Fixed-axis cycloid transmission device

A transmission device and fixed shaft technology, which is applied in the direction of transmission device, gear transmission device, belt/chain/gear, etc., can solve the problem of reducing transmission efficiency, transmission stability and carrying capacity, complicated installation and disassembly process, and high assembly precision requirements, etc. problem, to improve the transmission efficiency and transmission stability, simplify the installation and disassembly process, and expand the layout space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

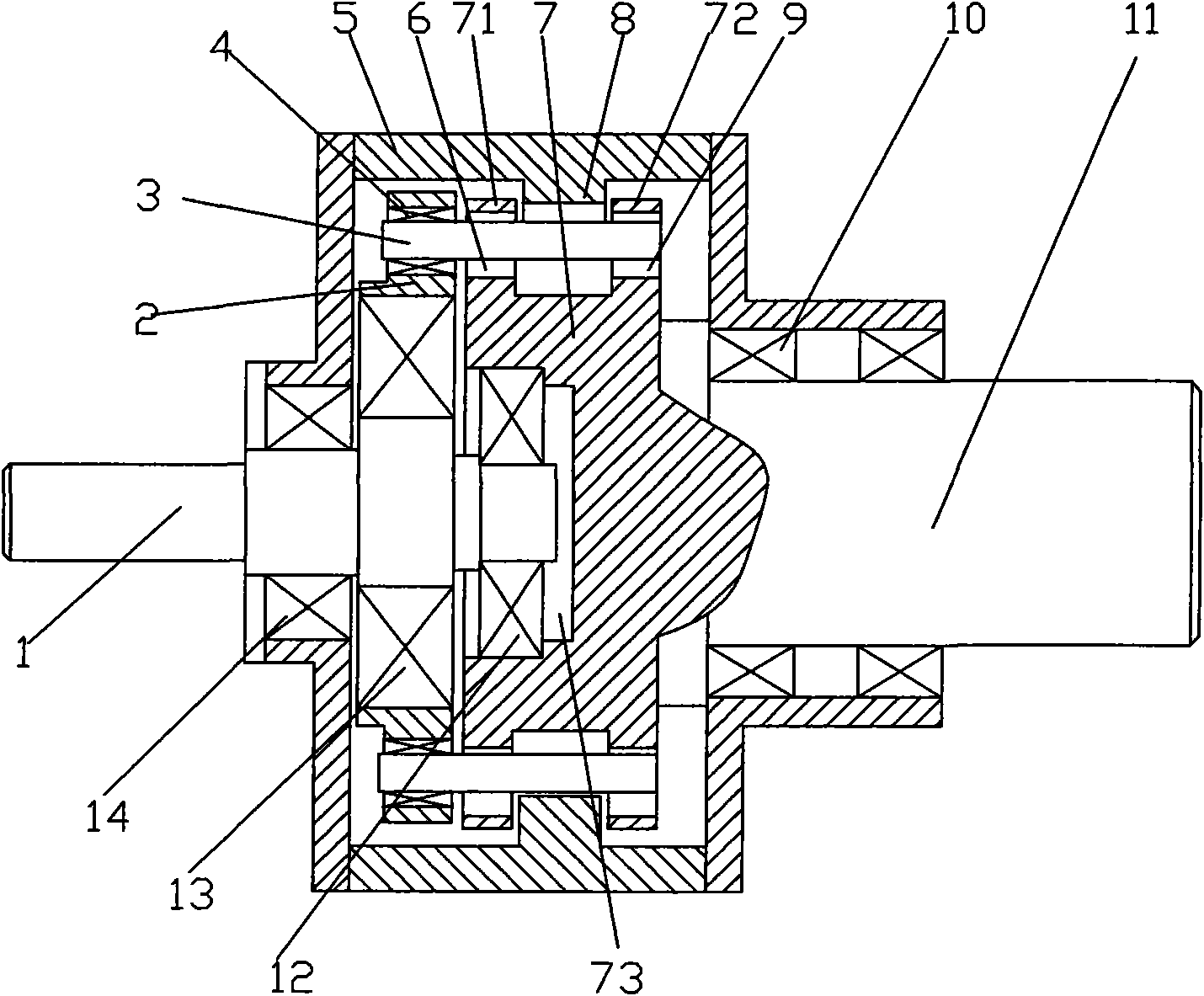

[0018] The accompanying drawing is a structural schematic diagram of the present invention, as shown in the figure: the fixed-axis cycloid transmission device of this embodiment includes a housing 5, a power input shaft 1 and a power output shaft that are coaxially arranged and respectively rotatably matched with the housing 5 11. In the figure, the power input shaft 1 and the power output shaft 11 are rotationally matched with the housing 5 through the rolling bearing 14 and the rolling bearing 10 respectively; The power take-off disk 7 is set in cooperation. In this embodiment, the power take-off shaft 11 and the power take-off disk 7 are fixedly matched in the circumferential direction by making one body to achieve the purpose of transmission cooperation; the drive disk 2 and the power take-off disk 7 Arranged side by side in the axial direction; evenly distributed along the circumferential direction of the driving disc 2, the transmission pin 3 is arranged to form a pin whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com