Device with middle lead screw and tailstock for numerical control lathe

A technology of CNC lathes and tailstocks, which is applied in the direction of feeding devices, tailstocks/tops, turning equipment, etc. It can solve the problems of cumbersome installation and debugging of machine tools, large overall quality of CNC machine tools, and inability to carry tailstocks, etc., to achieve loading and unloading Easy, small driving torque, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

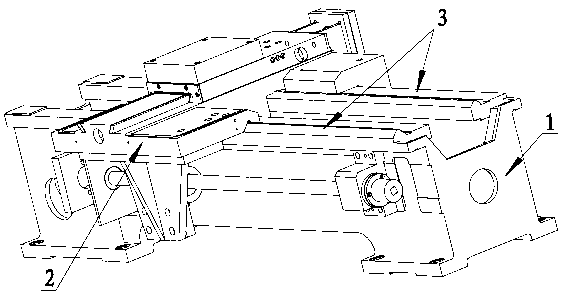

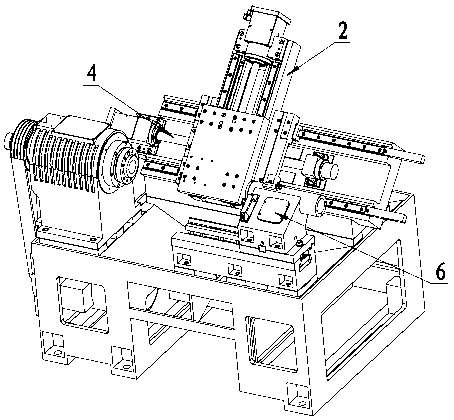

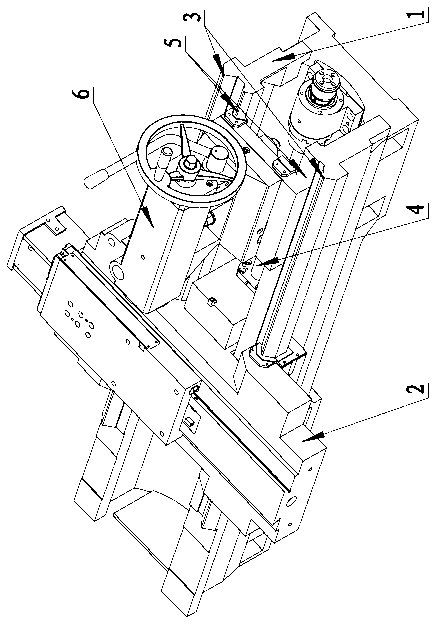

[0018] See attached image 3 , the structure shown in the figure is the first embodiment of the screw rod with tailstock device in the middle of the CNC lathe, including two guide rails 3 integrated with the bed 1, the large carriage 2 installed on the guide rail 3, and the large carriage 2 is connected to the screw rod 4 that controls the movement of the large carriage 2 on the guide rail 3; wherein: the screw rod 4 is arranged between the two guide rails 3, and a tailstock guide rail is arranged on the bed 1 next to the two guide rails 3 5. A tailstock 6 that moves along the tailstock guide rail 5 is provided on the tailstock guide rail 5 , and the tailstock 6 is located directly above the screw rod 4 . The threaded mandrel 4 is arranged in the mounting groove after the bed 1 sinks. This structure is based on the existing structure of the bed, the screw r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com