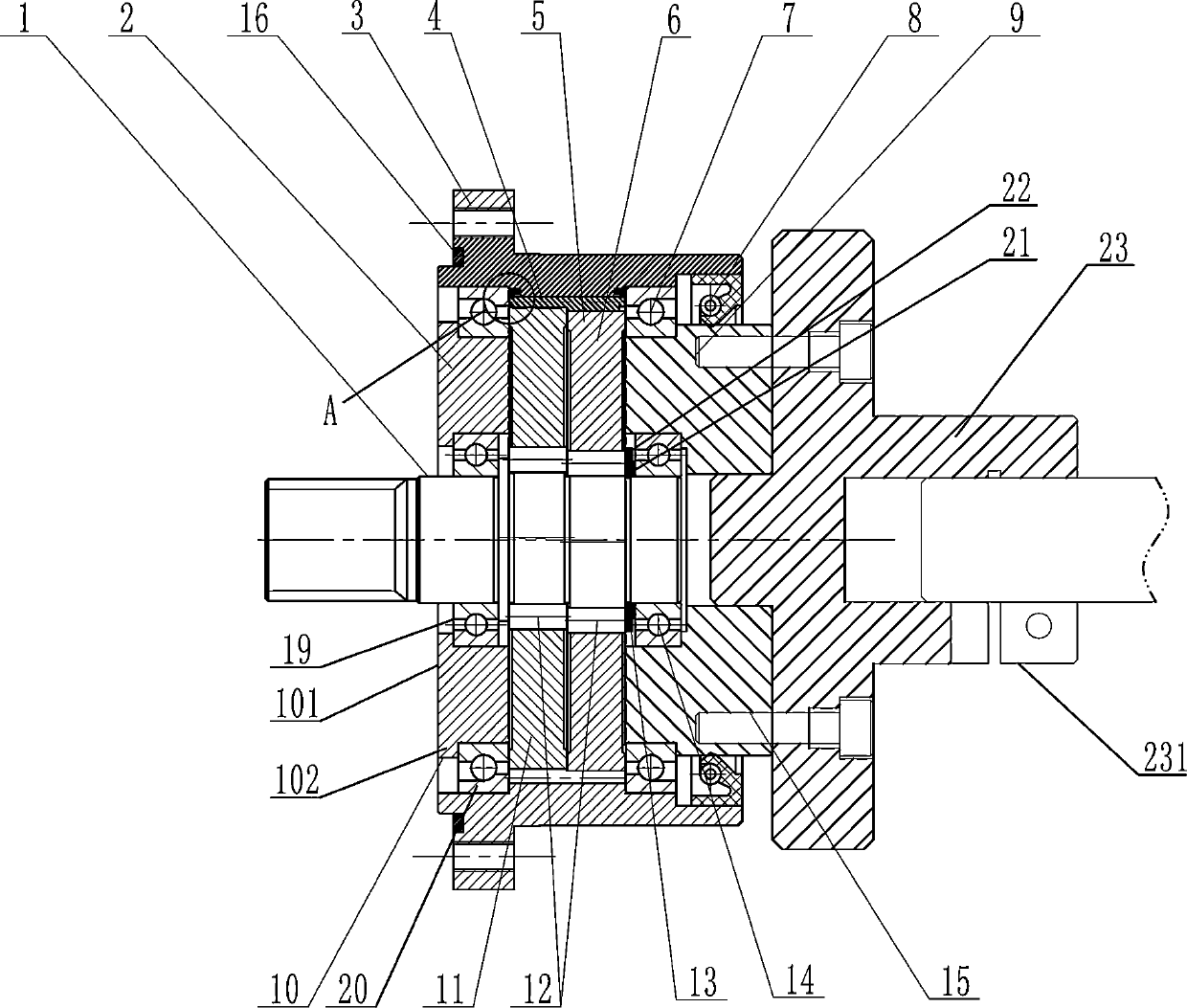

Output rapid chaining mechanism and speed reducer

A technology of output mechanism and reducer, applied in mechanical equipment, belt/chain/gear, transmission parts, etc., can solve the problems of damage to reducer, coaxiality error, long coupling installation time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

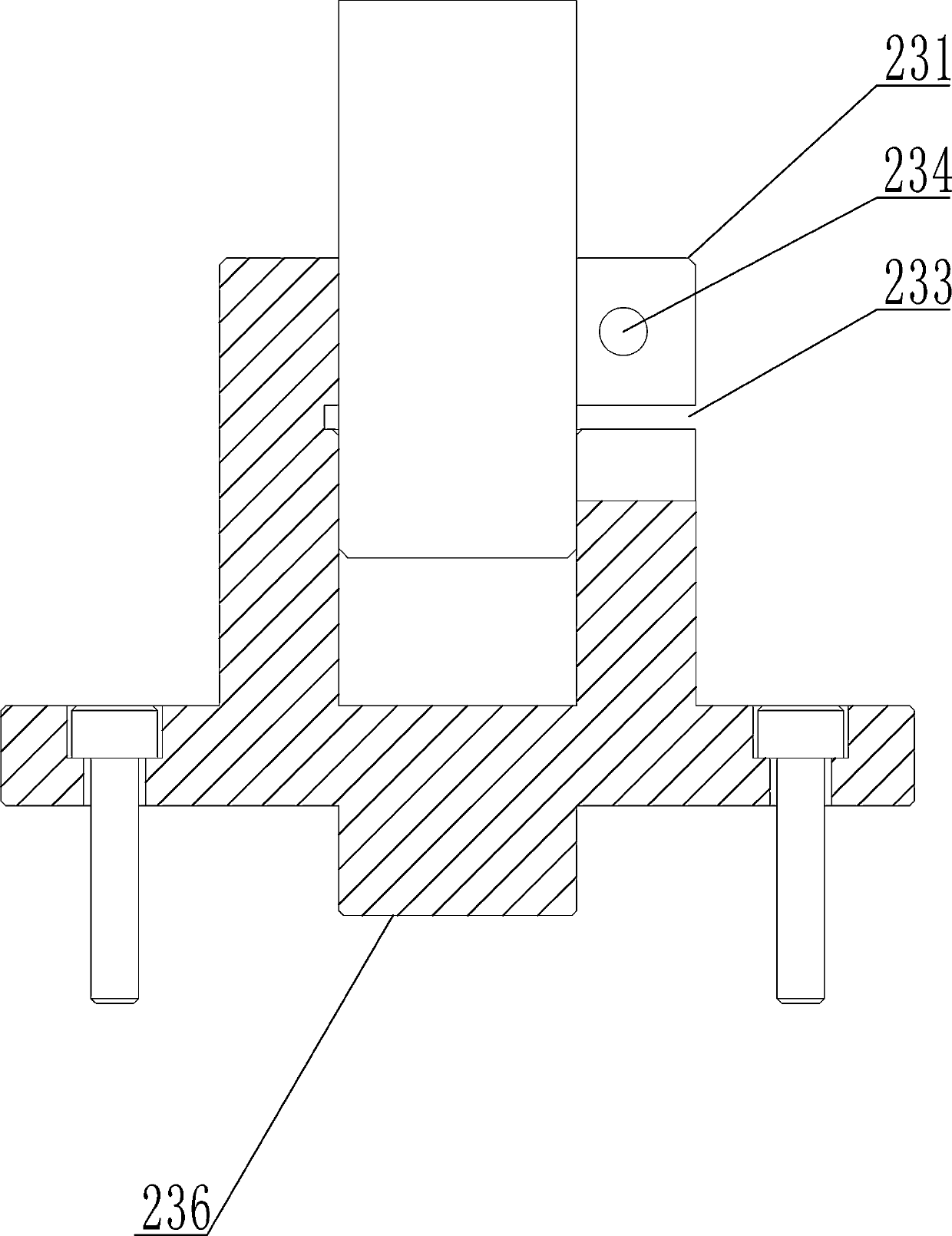

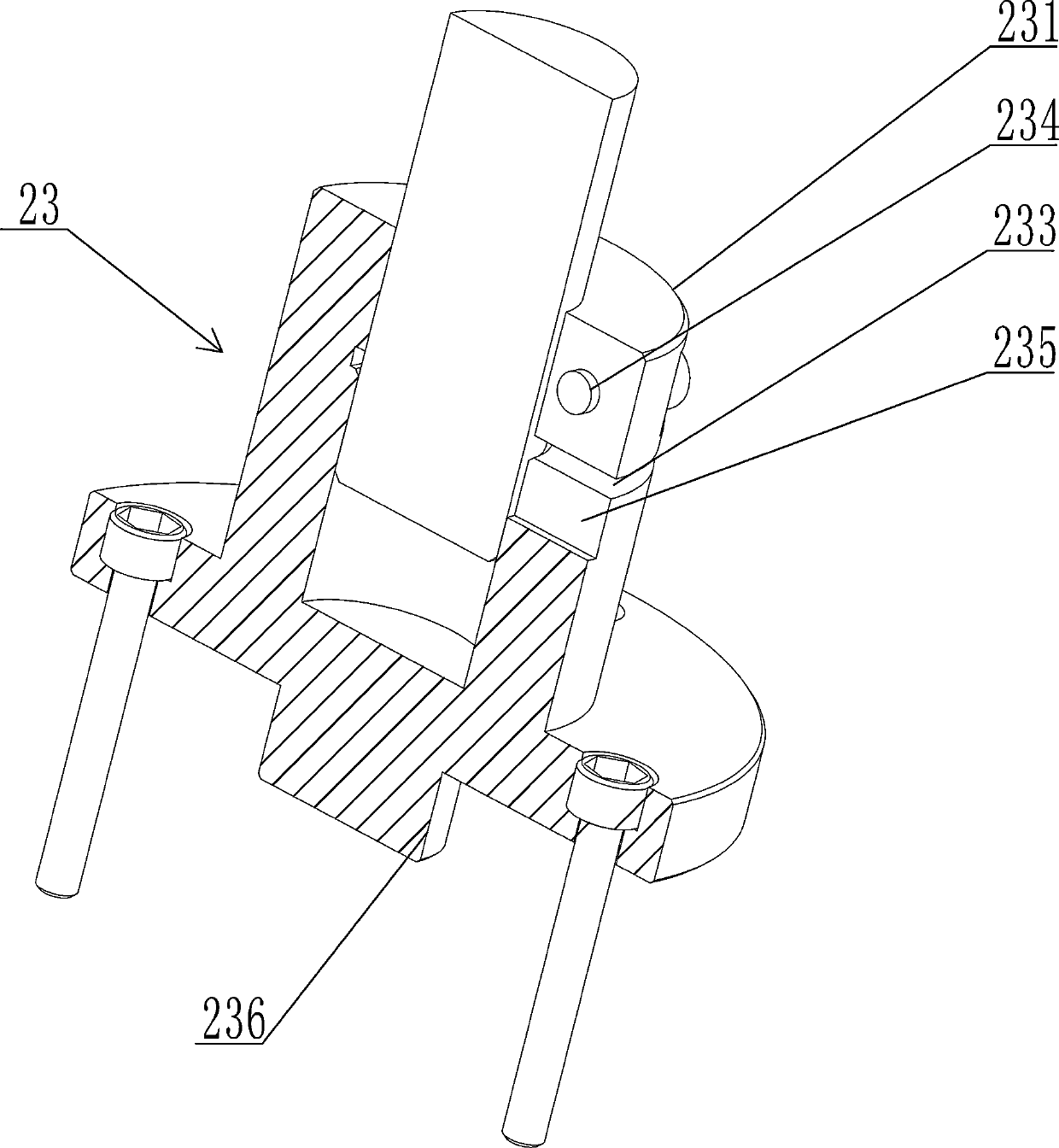

[0052] In combination with Embodiment 1, the installation method of the pin tooth positioning flange includes:

[0053] 1) Install one of the needle-tooth positioning flanges 24, install the positioning pin 25 on the positioning groove 31 inside the housing 3, and align the flange positioning groove 241 of the needle-tooth positioning flange 24 with the positioning pin 25 on the positioning groove 31 Cooperate to position the pin-tooth positioning flange 24, which plays the role of positioning and also plays the role of anti-rotation;

[0054] 2) After positioning, carry out cold fitting of the pin tooth positioning flange 24. After the installation is completed, install the pin tooth pin 4, cycloidal wheel 5, output seat 9 and input shaft 1. After the installation, install the second pin tooth Locate the flange 24, the installation method is the same as above, and the installation sequence prevents the problem that the cycloidal wheel 5 cannot be installed during installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com