Cam roller type numerical control indexing head

A technology of roller type and indexing head, which is applied in the direction of metal processing machinery parts, precision positioning equipment, metal processing equipment, etc., can solve the problem of poor rigidity ratio, small friction force, and limit the processing range of cam roller type CNC indexing head and other problems, to achieve the effect of improving transmission rigidity, improving stability, and maintaining motion processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

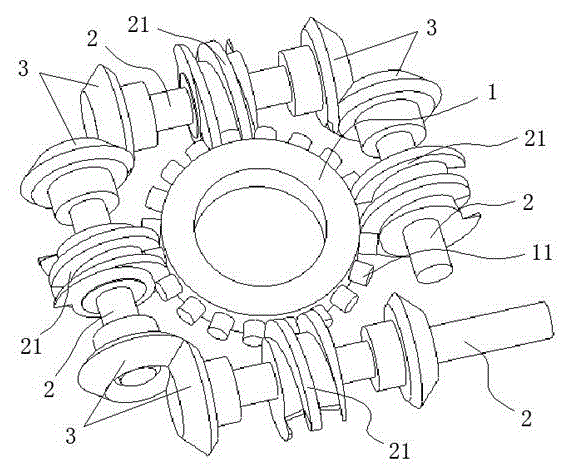

[0013] Such as figure 1 As shown, a cam-roller type numerical control indexing head mainly includes an indexing plate 1 and an arc-shaped cam 21 positioned on the transmission shaft 2, and the periphery of the indexing plate 1 is provided with a plurality of rollers evenly distributed on the circumference. Needle bearings 11 , each needle bearing 11 can engage with the arc cam 21 on the transmission shaft 2 in sequence.

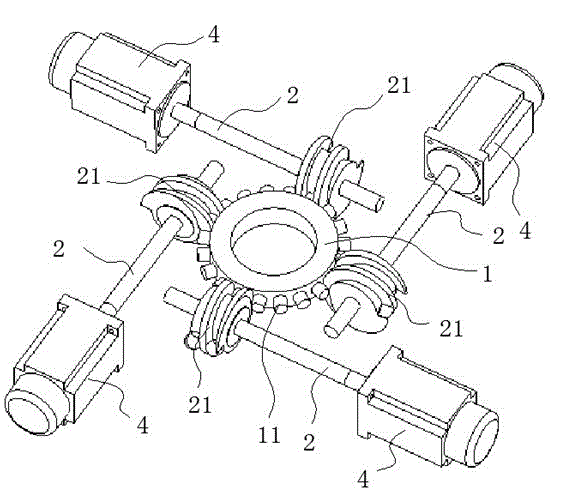

[0014] Here, in the present invention, there are at least two transmission shafts 2 with arc cams 21, and four transmission shafts 2 in this embodiment example, but in practice it can be set to two, three or more roots. The above transmission shafts 2 are sequentially connected to the transmission or driven synchronously by their own drive motors. In this embodiment, the structure of the transmission from the top to the bottom is adopted. In practice, it can be as follows: figure 2 As shown, each transmission shaft 2 is synchronously driven by its own driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com