Ram type main transmission mechanism for milling machine

A main transmission and ram technology, applied in the direction of driving devices, metal processing machinery parts, clamping, etc., can solve the problems of low installation and maintenance efficiency, large ram structure, poor transmission rigidity, etc., and achieve simple structure and transmission rigidity Good, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

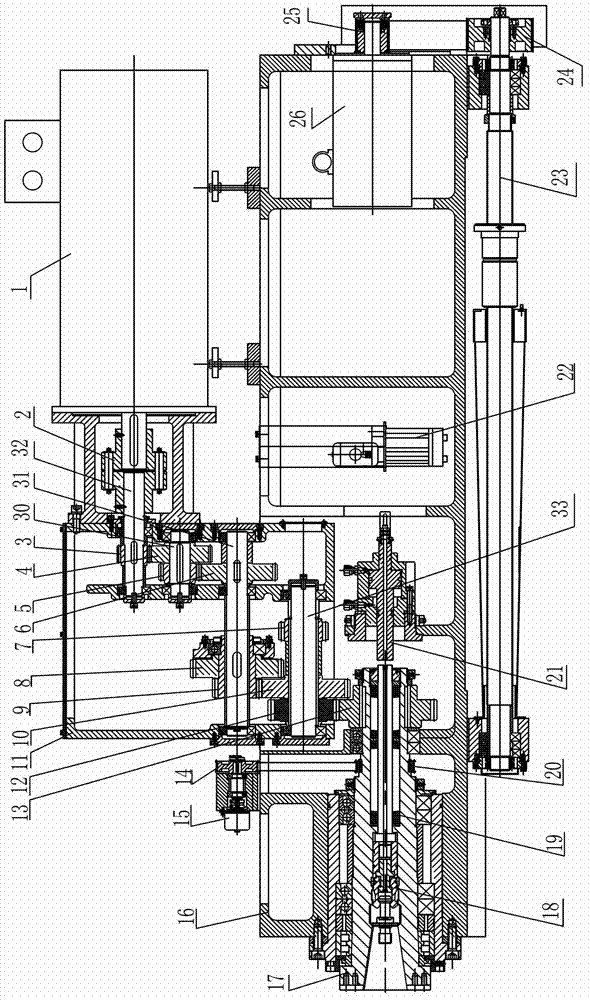

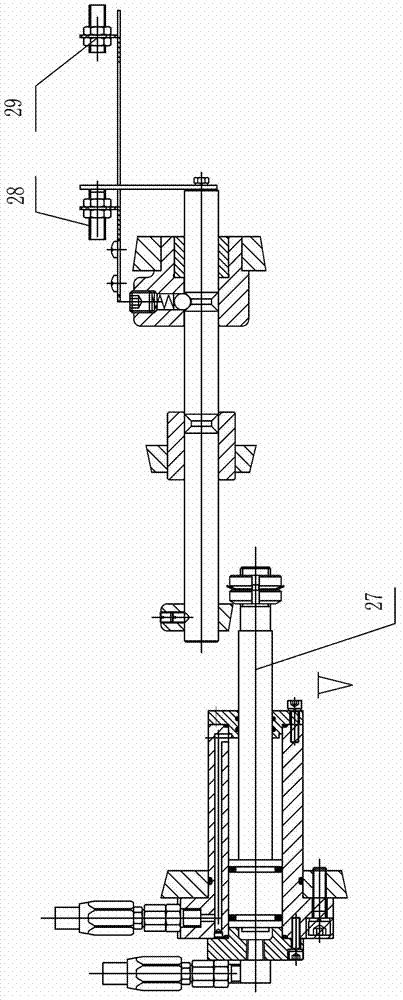

[0016] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] The ram-type main transmission mechanism of the milling machine of the present invention transmits the power of the drive motor (spindle drive servo motor 1) to the machine tool spindle 17 through the transmission device, and the machine tool spindle 17 drives the tool to rotate to realize milling.

[0018] Described machine tool main shaft 17 is arranged on ram 16 front parts, machine tool main shaft gear 13 and machine tool main shaft 17 are coaxially fixed, and machine tool main shaft 17 is provided with the automatic purging device that constitutes main shaft assembly, automatic broaching device 18, hydraulic pressure unclamping device. Device 21 and disc spring tensioning device 19, the tensioning and loosening of the tool are controlled by PC, when automatic tool changing, the automatic purging device starts to work to clean the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com