Highly-thrust-resistant pin structure for connecting constructional steel column with constructional steel pipe truss

A technology of steel pipe trusses and construction steels, which is applied in building construction and construction, and can solve the problems of small axial thrust bearing capacity, poor integrity, and limited use of pin-shaft connections, so as to improve the overall rigidity and strength, and the overall Effects of performance improvement and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

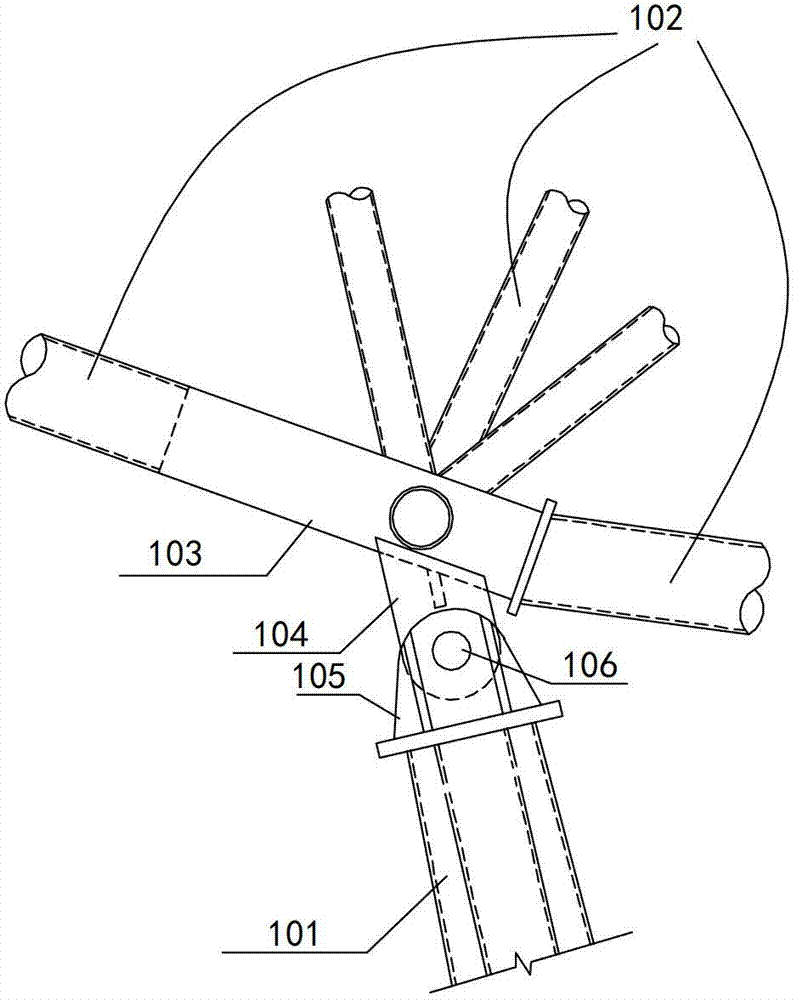

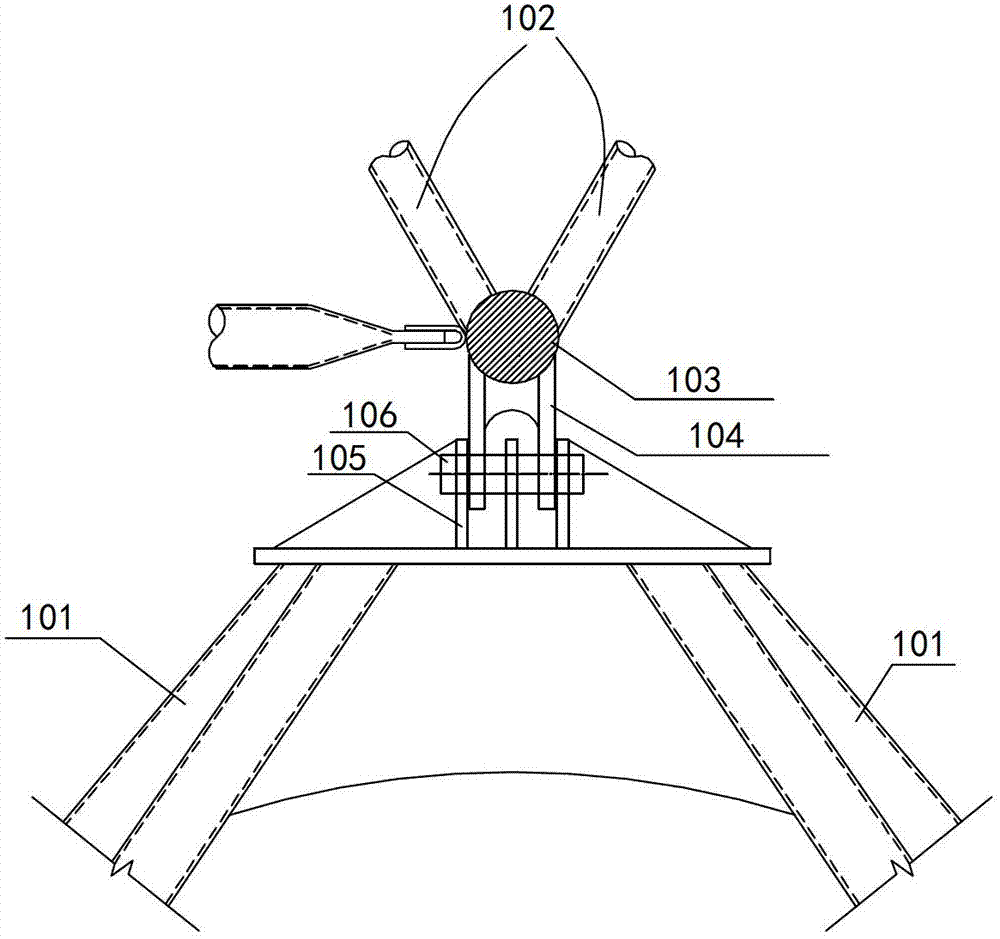

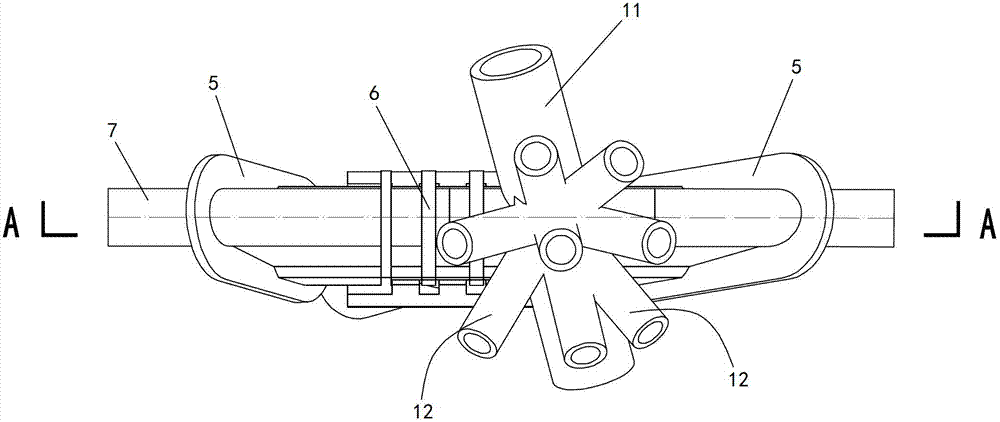

[0040] Such as Figure 3 to Figure 9 A large anti-thrust pin shaft structure for connecting building steel columns and steel pipe trusses is shown, including truss nodes, pin shaft connection seats, pin shafts 8 and anti-off safety caps 10, wherein the truss nodes are integrally cast and formed, and the truss The node is used to connect with the building steel pipe truss 102. The specific connection method is that the truss node is welded with the building steel pipe truss 102. The pin shaft connection seat is used for fixed connection with the building steel column. The truss node is an integrally cast steel casting. The connection seat is also an integrally cast steel casting, which is the existing high-toughness and high-strength weldable cast steel. Save material and reduce self-weight, the truss node and the pin connection seat have a structure that fits each other, and both the truss node and the pin connection seat have pin holes for the pin shaft 8 to pass through, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com