Uniform-load thrust sliding bearing group for downhole power drilling tools

A technology for thrust sliding bearings and power drilling tools, which is applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., and can solve the problem of bearing group load sharing design and lack of lubrication performance, which is difficult to adapt to ultra-deep well high temperature working environment, single-width bearings Unstable life of the bearing group and other problems, to achieve the effect of compact structure, good wear resistance and short length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

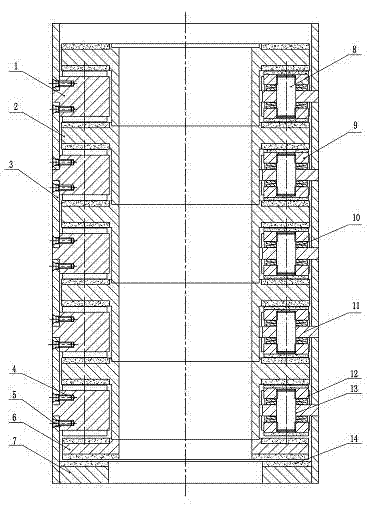

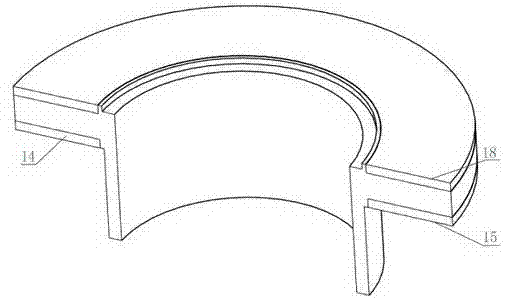

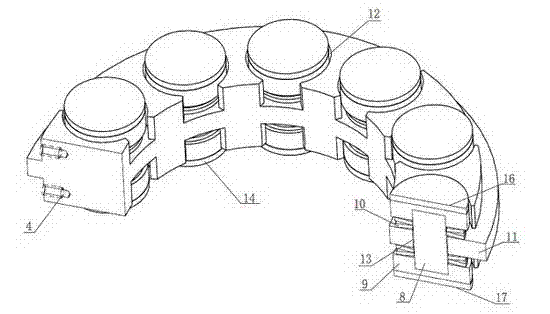

[0016] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a load sharing thrust sliding bearing group of a downhole power drilling tool according to the present invention is mainly composed of a static ring 1, a moving ring 2, an outer sleeve 3, an overload protection moving ring 6 and an overload protection static ring 7. The static ring is composed of a connecting stud 8, a thrust tile 9, a butterfly spring 10, and a static ring base 11; 10 to 16 counterbores 12 are evenly distributed on the circumference of the front and back sides of the static ring base 11, and the counterbores There is a through hole 13 in the center of 12; the connecting stud 8 passes through the through hole 13 and is threadedly connected with the thrust tile 9, and the butterfly spring 10 is fixed between the thrust tile 9 and the static ring base 11, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com