Pressure fluctuation fatigue test device for train door

A pressure pulsation and fatigue test technology, applied in the field of door fatigue test and pressure pulsation fatigue test device of train doors, can solve the problems of high cost, occupation of railway transportation resources, time-consuming and other problems, and achieve low cost, low energy consumption, and easy assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

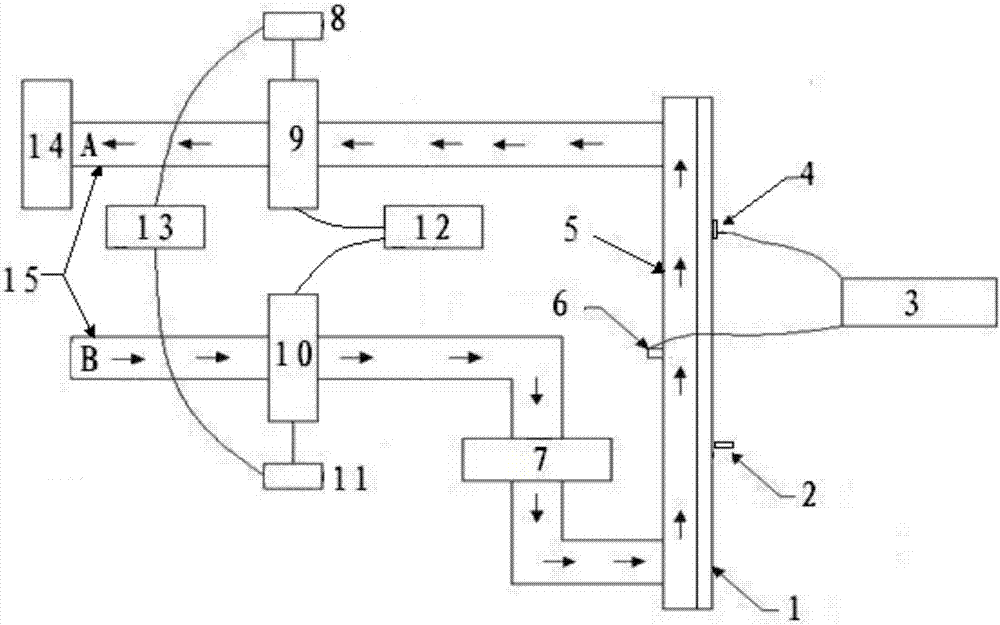

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] The invention is a pressure pulsation fatigue test device for train doors, which is used to generate pressure pulsations of positive pressure or negative pressure or zero-average positive and negative pressure on one side of the train door, and simultaneously measure the pressure pulsation value and the relationship between the door and the window. displacement and strain.

[0024] Such as figure 1 As shown, the test piece is a car door 1, and the test device of the present invention includes: a test circuit, a control assembly and a measurement assembly; wherein, the test circuit includes an installation tool 5 and a pipeline 15, and the control assembly includes a shut-off valve 7, a first electromagnetic valve 8. The first pneumatic valve 9, the second pneumatic valve 10, the second solenoid valve 11, the air source 12, the PLC controller 13 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com