Cross compression sample holder for dual-axis loading system and loading method

A sample fixture and shaft loading technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that the accuracy of the experiment cannot be compared with the biaxial loading system, the biaxial compression cannot be solved, and the structure of the test equipment is complex, etc., and the weight can be achieved. Lightweight, simple device structure, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

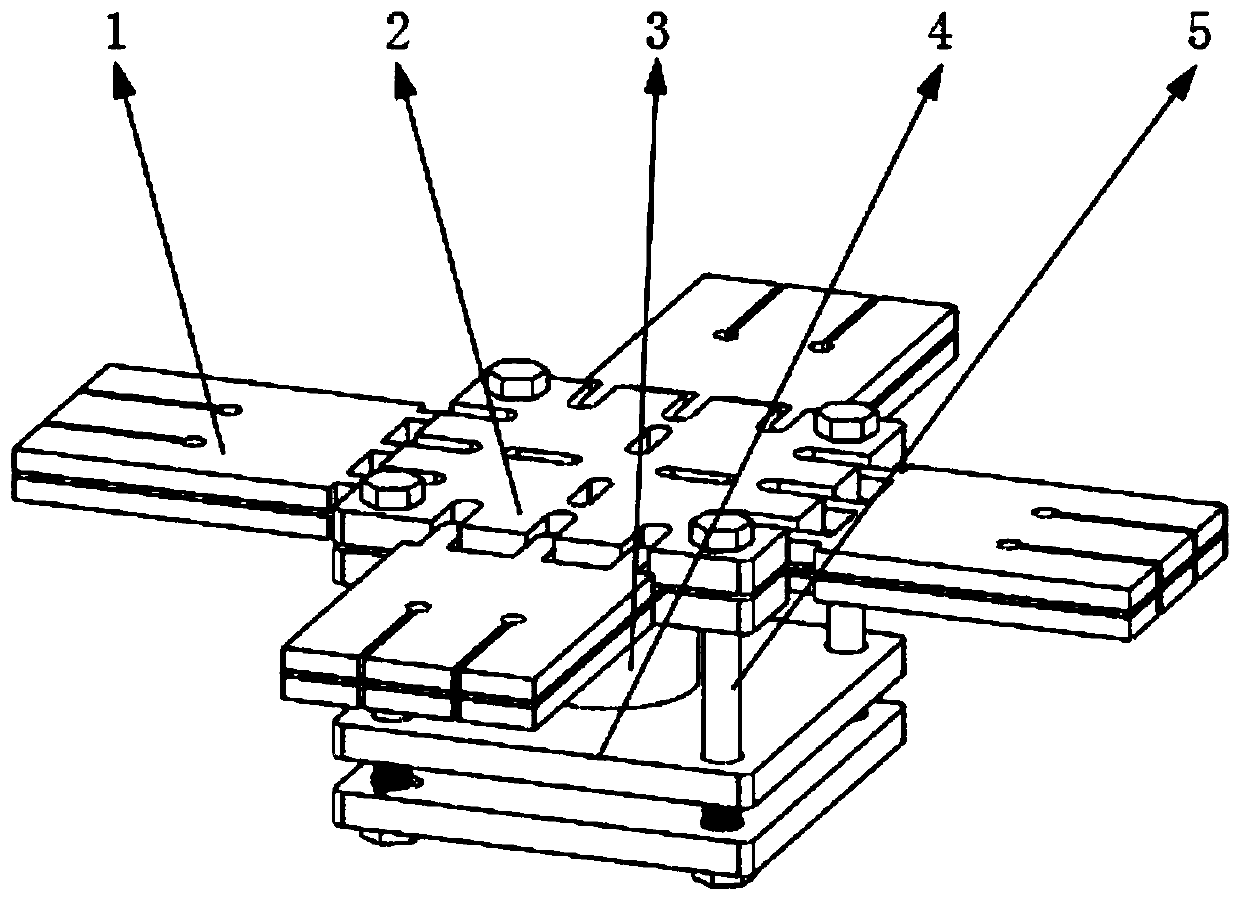

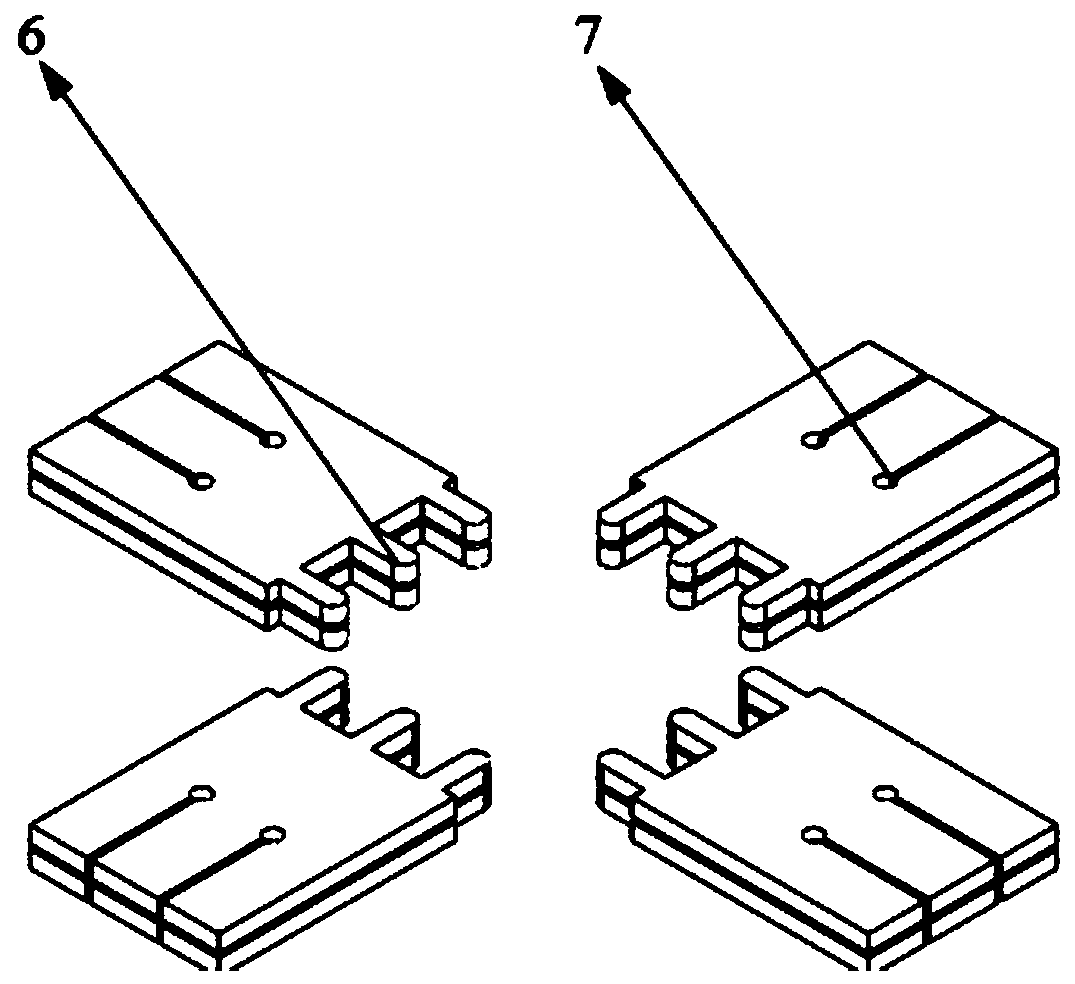

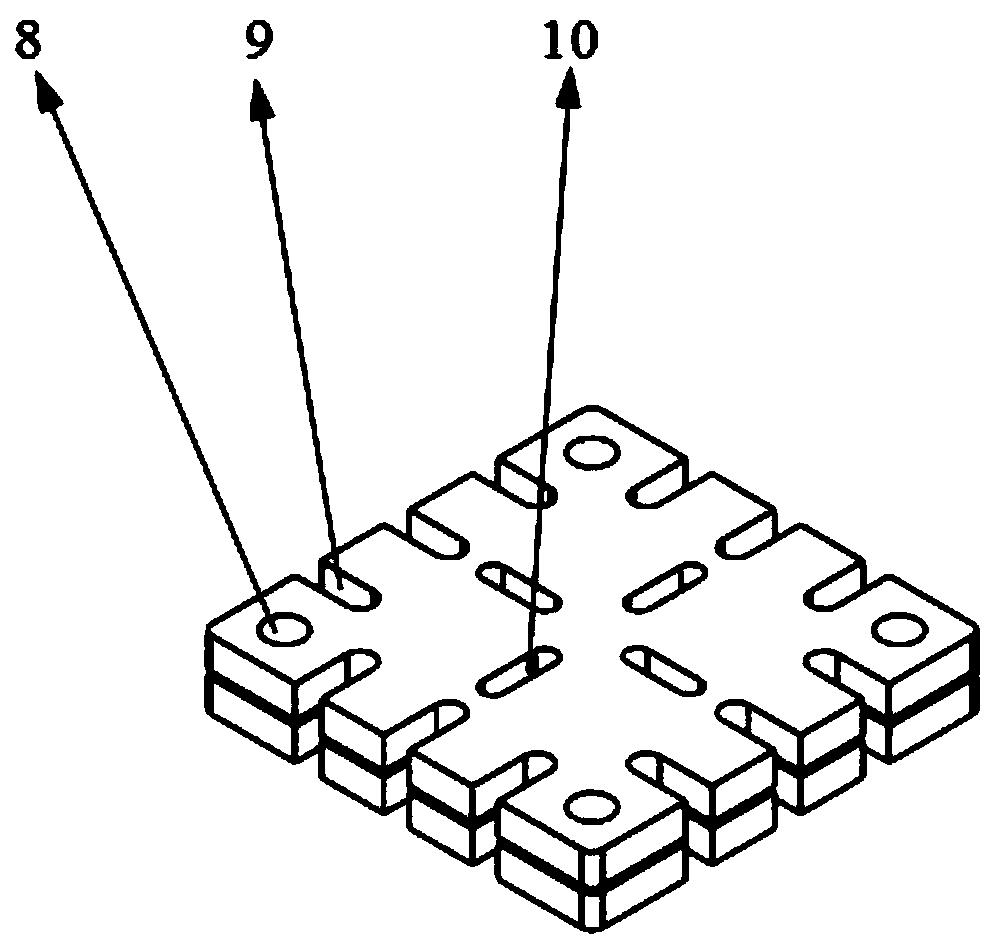

[0039] like Figure 1-6 As shown, this embodiment provides a cross-compression specimen fixture for a biaxial loading system, which consists of four clamping ends 1 , a loading block 2 , a pressure sensor 3 , and a base 4 . The four clamping ends 1 are respectively located on each loading arm of the cross compression sample 13, and the clamping end 1 is provided with a positioning hole 7, which is convenient for adjusting the position and fixing of the cross compression sample 13, and the loading pressure block 2 acts on the cross compression sample 13 to receive force area to avoid bending during compression.

[0040] In this embodiment, the clamping end 1 is provided with upper and lower layers, which is a detachable structure, and the cross compression sample 13 is placed in the middle of the clamping end 1, and fixed with the clamping end 1 through the positioning hole 7 by the bolt 5; For samples with different thicknesses, nuts of different sizes can be used for adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com