Double-cylinder electric nail fixing device

A double-cylinder, electric technology, applied in the direction of nailing tools, staple nailing tools, manufacturing tools, etc., can solve the problems of unstable nailing effect, difficulty in realizing the limit of the firing pin, small volume of the small cylinder, etc. The process of reset and pressurized energy storage is stable, the control method is simple and effective, and the effect of prolonging the gas supply cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

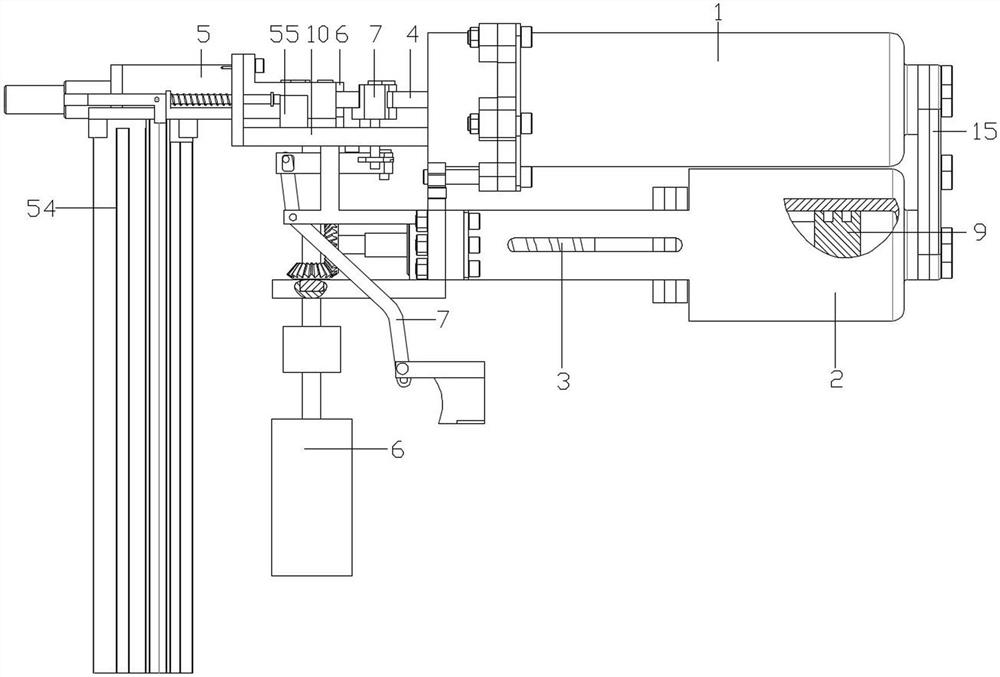

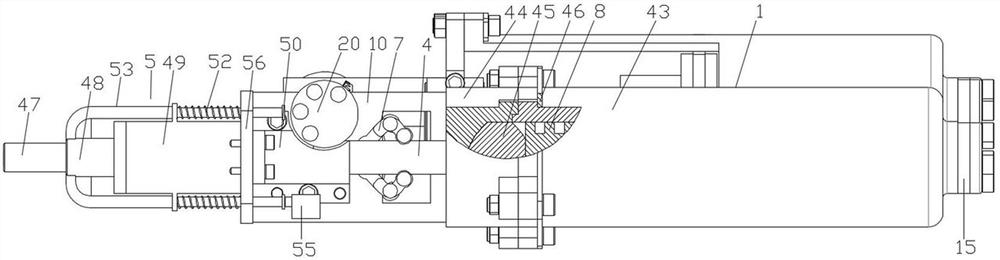

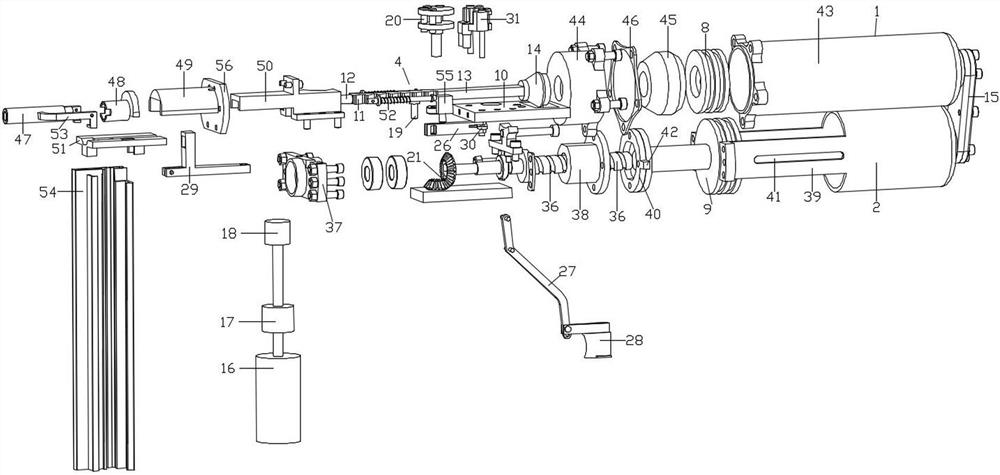

[0067] As a basic embodiment of the present invention, the present invention discloses a double-cylinder electric nail fixer, such as Figure 1-3 As shown, the stapler includes a main cylinder 1 , a secondary cylinder 2 , a linear motion mechanism 3 , a firing needle 4 , a needle tube assembly 5 , a drive mechanism 6 and a limit release mechanism 7 . Taking the direction shown as an example, the left end of the master cylinder 1 and the left end of the sub cylinder 2 are set as the front end, and the right end of the master cylinder 1 and the right end of the sub cylinder 2 are set as the rear end. Among them, the structure, position and connection relationship of each component are as follows:

[0068] The main cylinder 1 is fixedly connected with the auxiliary cylinder 2 , and preferably, the fixed main cylinder 1 is located directly above the auxiliary cylinder 2 . The main cylinder 1 and the auxiliary cylinder 2 are respectively provided with the main piston 8 and the aux...

Embodiment 2

[0076] As a preferred embodiment of the present invention, on the basis of Embodiment 1, this embodiment further improves the master cylinder 1 . like Figure 2-3 As shown, the master cylinder 1 includes a cylinder block 43, a cylinder head 44, a damping pad 45 and a washer 46, the cylinder head 44 is sealed and fixed on the cylinder block 43 by bolts, and the washer 46 is provided with bolt holes around it, and the washer 46 It is fixed between the cylinder head 44 and the cylinder block 43 by bolts and bolt holes, and the shock absorbing pad 45 is fixed in the cylinder head 44 to reduce vibration during the use of the injection gun. The cylinder head 44 has a certain internal space. In order to improve the damping effect, it is preferable that the size and shape of the damping pad 45 are adapted to the internal space of the cylinder head 44, even if the internal space of the cylinder head 44 is completely covered by the damping pad Seat 45 is filled.

Embodiment 3

[0078] As another preferred embodiment of the present invention, on the basis of Embodiment 1, this embodiment further improves the needle tube assembly 5 . like Figure 1-3 As shown, the needle tube assembly 5 includes a needle tube 47 , a needle tube cover 48 , a firing needle guide cover 49 , a firing needle guide seat 50 , a bottom plate 51 and an elastic reset member 52 . The firing pin guide cover 49 has a semicircular structure, the rear end of which is fixed with a fixing plate 56 that is fixedly connected with the connecting piece 10 , and the bottom surface is flat, and a groove is formed on the flat surface. The main body of the firing pin guide seat 50 is a square structure, its bottom surface is provided with a firing channel for the firing pin 4 to move, its front end is matched with the groove on the firing pin guide cover 49, and its rear end and the upper part of the middle part are provided with fixed Structure, the front end of the firing pin guide seat 50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com