New-type sheet cutter

A technology of cutter and thin plate, which is applied in the direction of cutting device, shearing device, shearing machine equipment, etc. by nibbling action, which can solve the problems of not being on the entire circumference, scrapping after wear, unable to change, loose of the knife seat, etc. To achieve the effect of convenient cutting edge adjustment and transformation, convenient replacement and disassembly, and large axial punching and shearing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

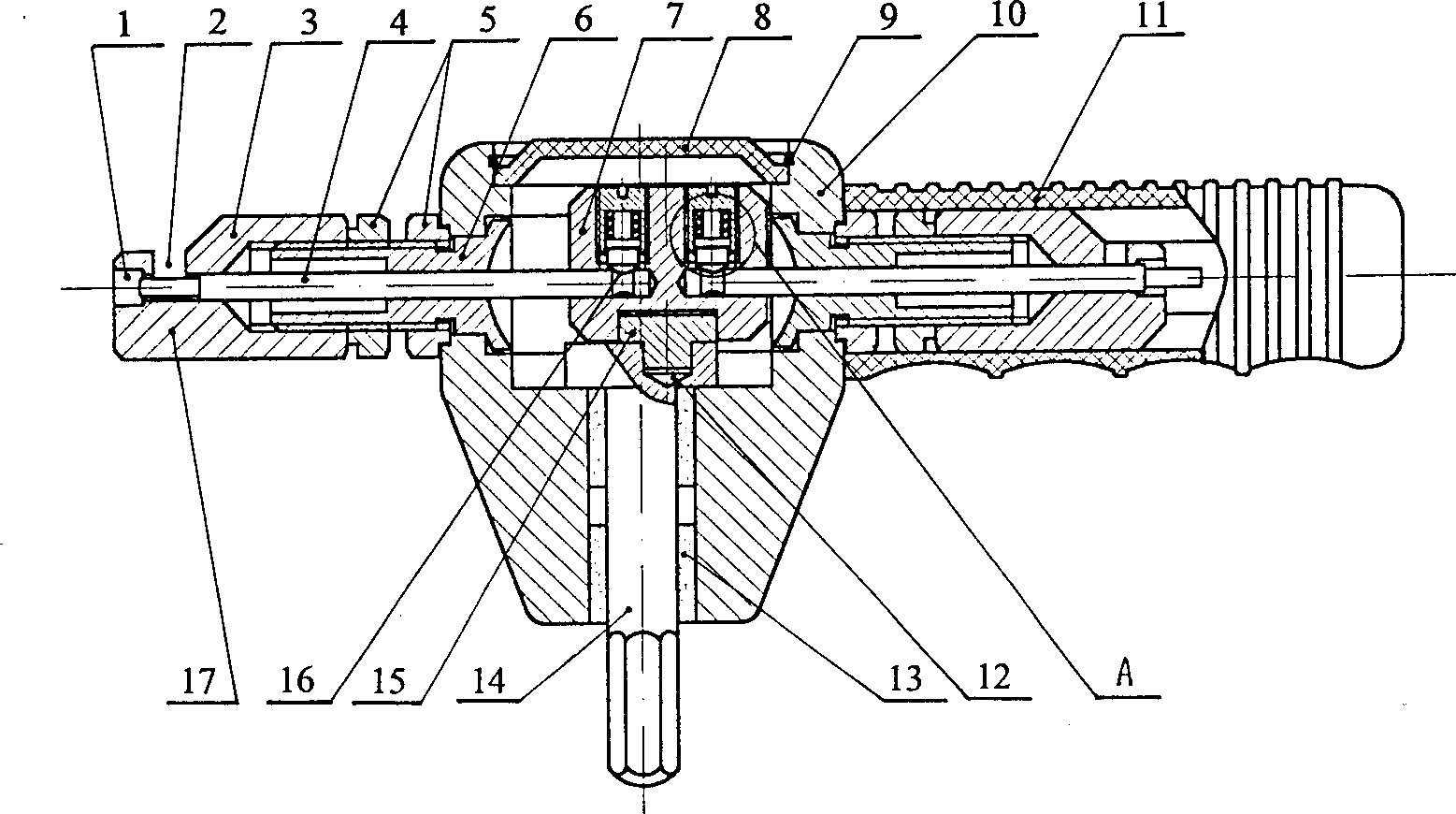

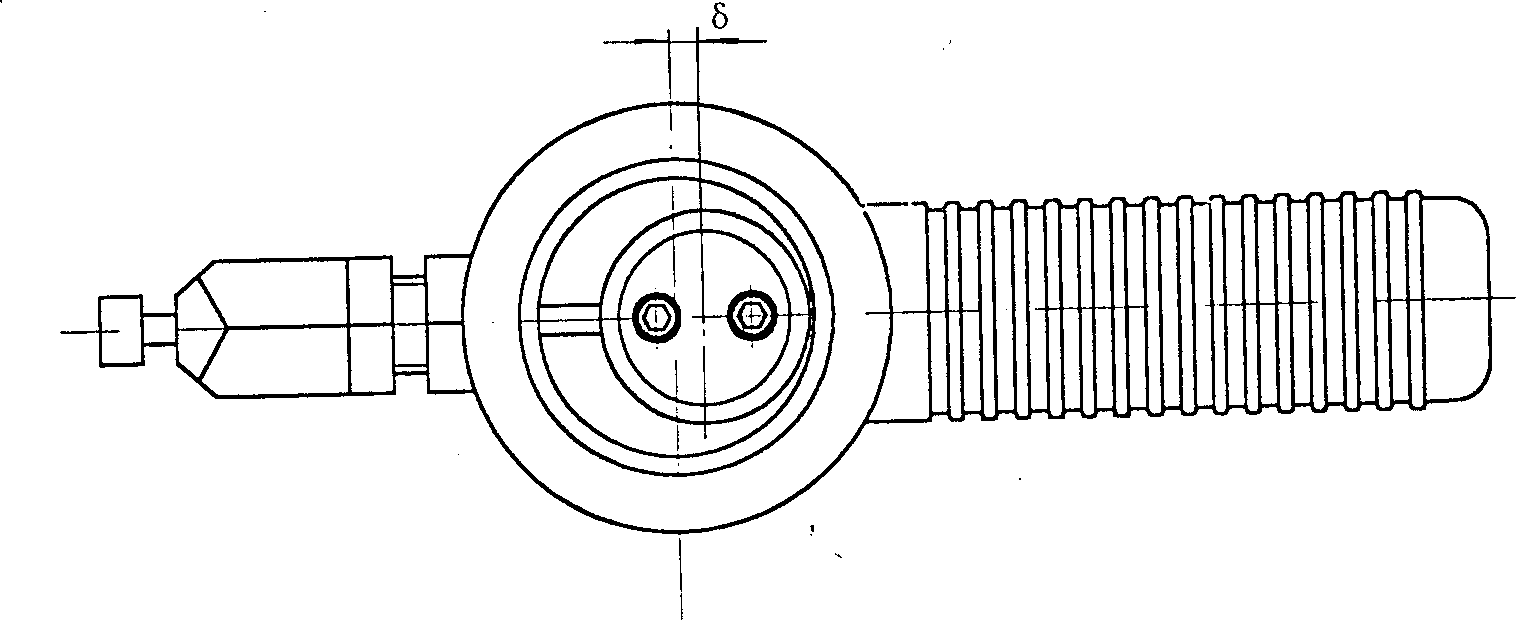

[0024] Such as Figure 1-13 As shown, the new sheet cutter is used in conjunction with a pistol electric drill, which can cut metal sheets below 2.2 mm or non-metal sheets below 5 mm, and can also cut arbitrary curves and round holes with a diameter greater than 25 mm. The cutting speed is fast, up to 1 m / min or more.

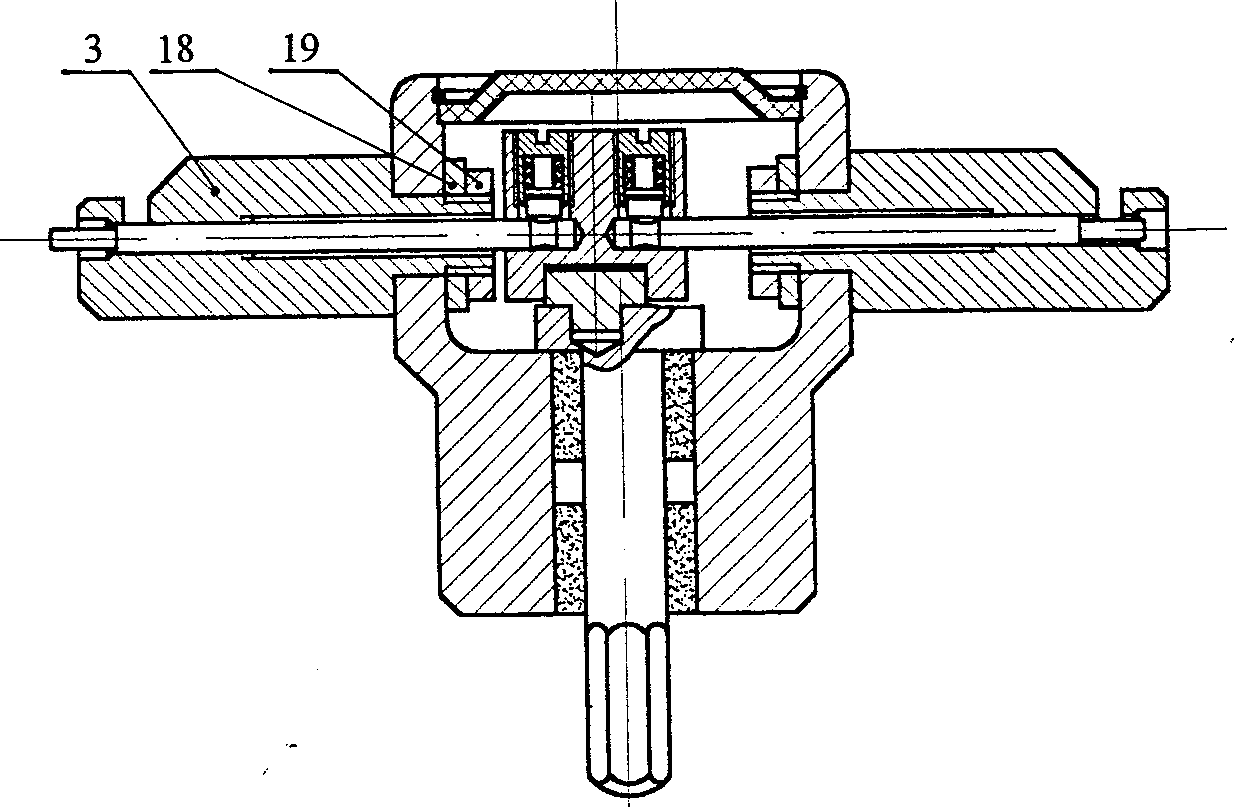

[0025] This cutter has a body 10 with a circular, conical or hexagonal shape, and the body has coaxial shaft holes that are perpendicular to each other and communicate with each other. figure 1 In the shaft hole in the vertical direction, there is an eccentric shaft 14 supported by an oil bearing 13 and driven by an external force with an eccentric distance δ of 2.5-3.5 mm. The eccentric shaft is embedded in the "T" shaft by a common "T" shaft The lower block 15 at the eccentric position of the end is formed, and a lubricating oil st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com