Crystallizing tank for boiling sugar

A crystallization tank and sugar cooking technology, which is applied in sugar crystallization, sugar production, food science, etc., can solve the problems of crystallization tank without forced circulation device, uneven grain size, and increased color value of finished sugar, so as to avoid circulation obstruction , Reduce the loss of sugar and reduce the waste of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

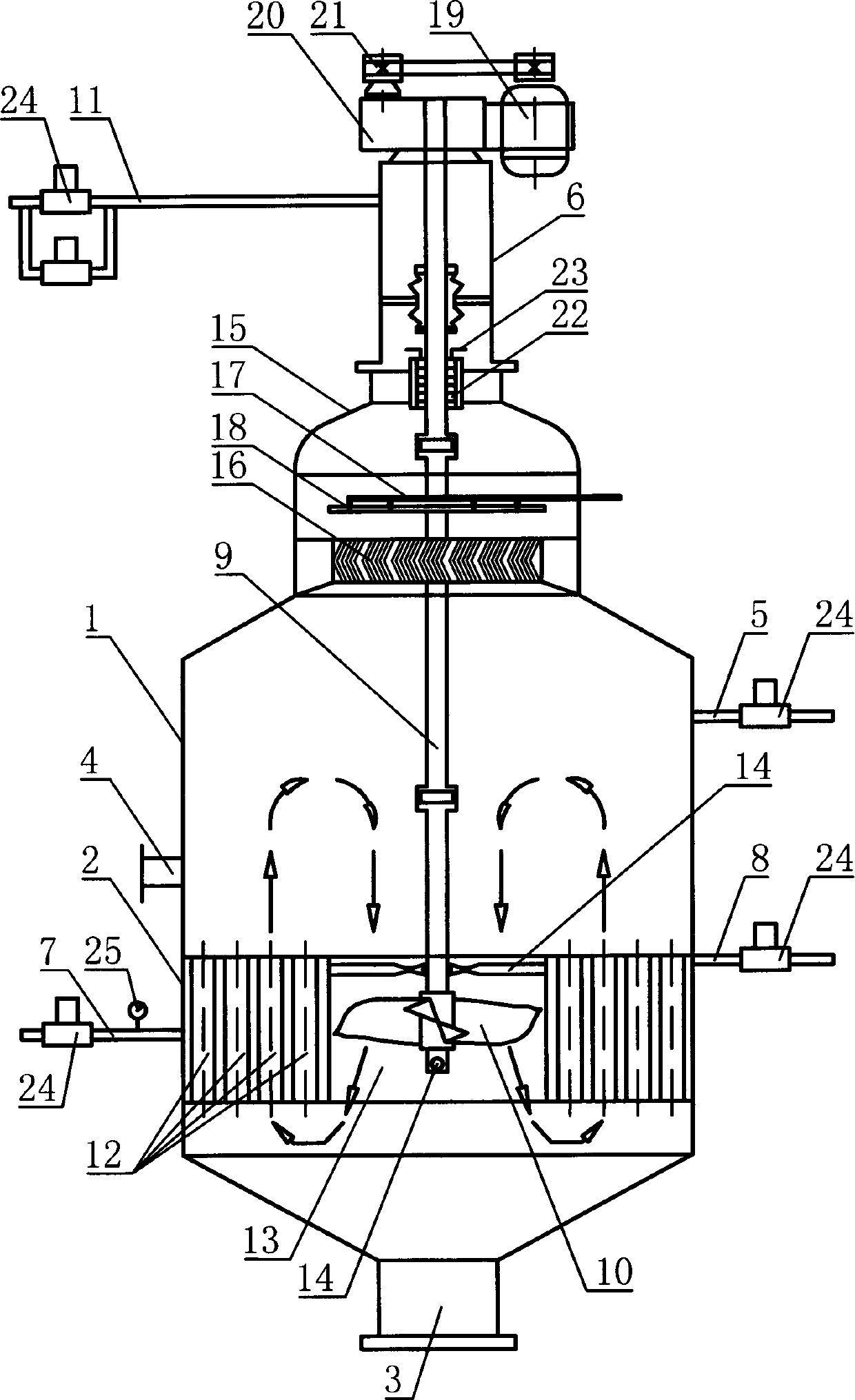

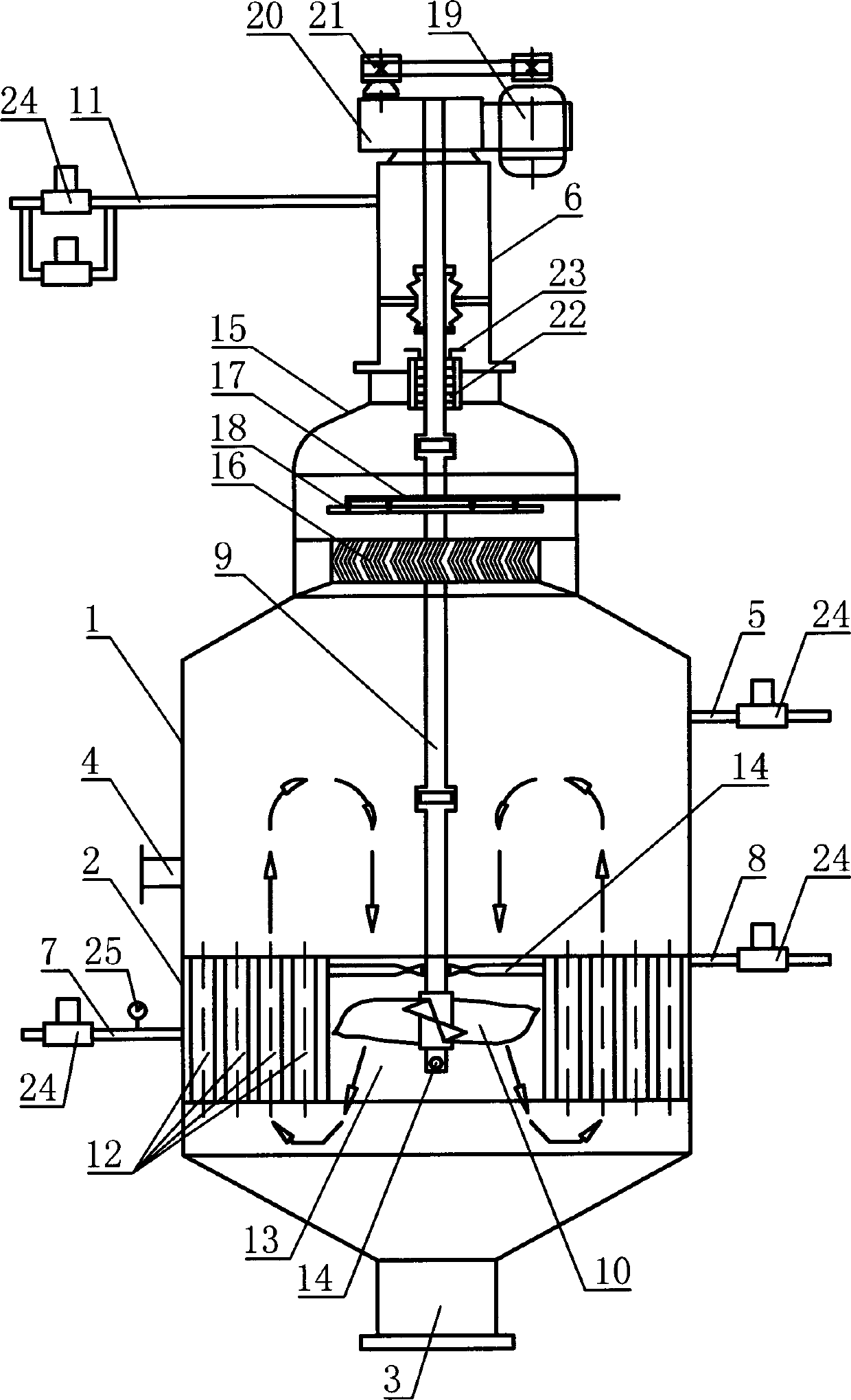

[0021] A boiling sugar crystallization tank according to the present invention comprises a tank body 1, an evaporator 2 arranged inside the tank body 1, a discharge opening 3 arranged at the bottom of the tank body 1, and a feed inlet 4 arranged on the side wall of the tank body 1 And the vent pipe 5 is installed on the drive device above the tank body 1 through the support base 6, connected to the drive device and connected to the main shaft 9 extending into the inside of the tank body 1, connected to the vacuum tube 11 on one side of the support base 6; The part corresponding to the evaporator 2 inside the tank body 1 is a heating chamber, and the part above the evaporator 2 is an evaporation chamber; the steam input pipe 7 and the seed input pipe 8 are respectively communicated with the heating chamber; the main shaft 9 extends into the tank One end in the body 1 is equipped with a forced circulation paddle 10 arranged in the center of the evaporator 2 .

[0022] When using...

example 2

[0024] A sugar crystallization tank of the present invention, as shown in the figure, its evaporator 2 is a central circulation tube evaporator, composed of a heating tube 12 and a downcomer 13; the inner diameter of the downcomer 13 is larger than the forced circulation paddle The outer diameter of 10 is set in the middle; the heating tubes 12 are several vertical beam tubes, which are set around the downcomer 13. Adopting this central circulation tube evaporator can effectively improve the evaporation speed and efficiency, thereby The sugar cooking time is saved, the sugar cooking efficiency is improved, and energy saving and environmental protection are achieved.

[0025] Wherein, the top and bottom of the forced circulation paddle 10 are respectively symmetrically provided with stirring rods 14 installed on the main shaft 9, and the top and bottom stirring rods 14 are arranged perpendicular to each other, which can effectively improve the stirring effect of the forced circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com