Elastic self-locking full roller bearing and robot reduction gear thereof

A full-roller, elastic technology, applied in the field of elastic self-locking full-roller bearings and their robot reducers, can solve the problems of scattered rollers, inner rings and outer rings, reduced bearing performance, not standard parts, etc. Achieve the effect of preventing roller skew, reducing axial force and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

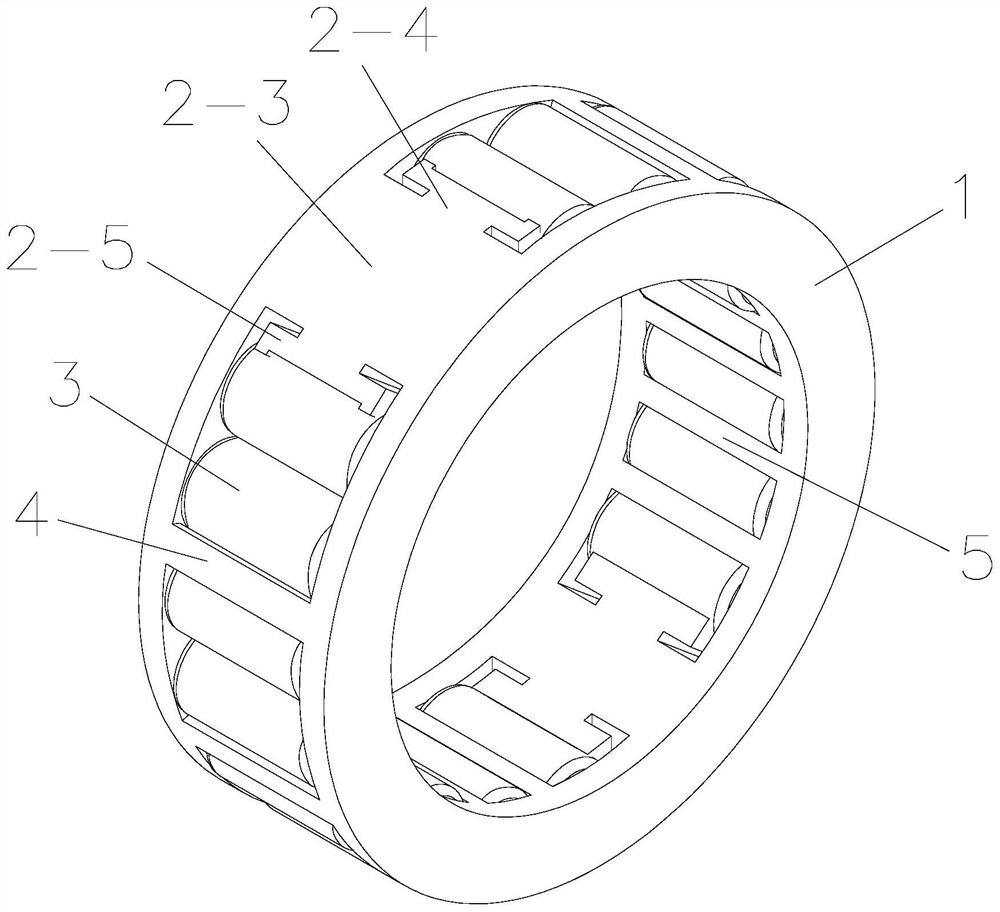

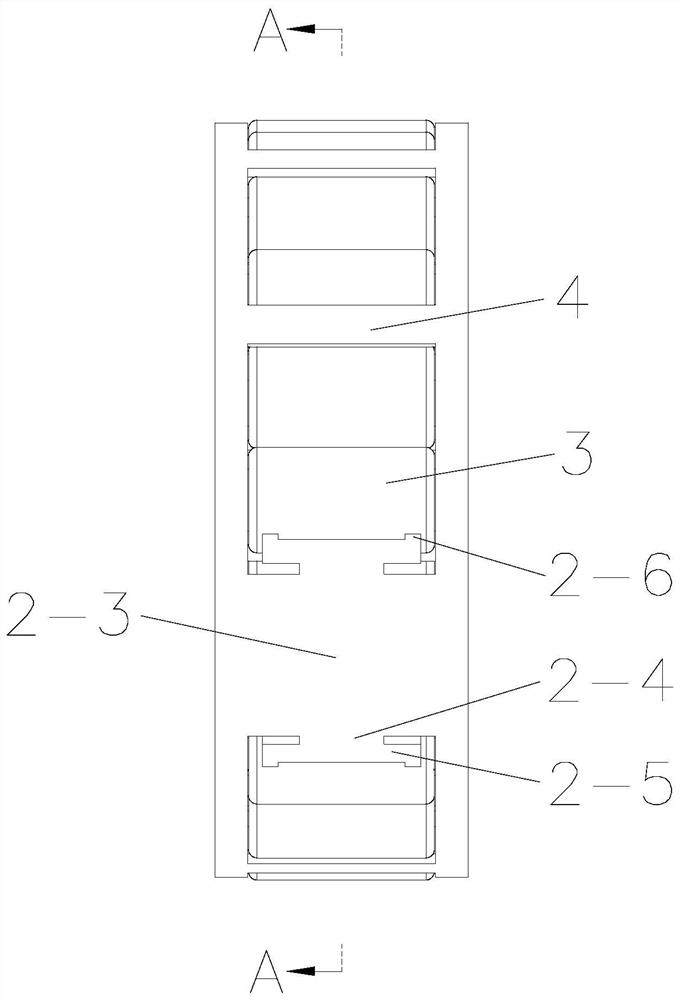

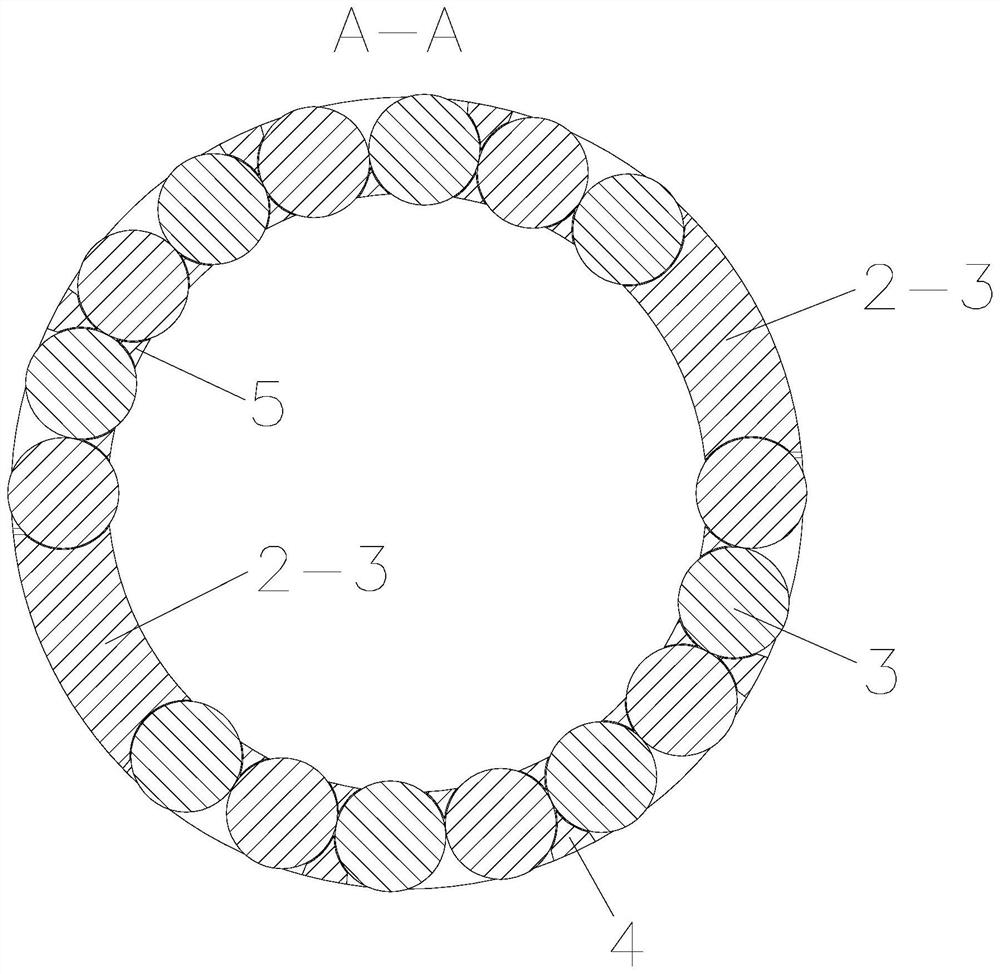

[0040] Such as Figure 1-Figure 5 The shown elastic self-locking full roller bearing includes a cage, and the cage includes two ring-shaped baffles 1, and also includes an elastic main beam, which includes a beam body 2-3, and a beam body 2- 3 Connected between two baffles 1, the two ends of the beam body 2-3 are respectively fixedly installed with the first elastic body and the second elastic body, and the space between the first elastic body and the second elastic body is fully filled with rollers 3 , the elastic main beam is used to adjust the circumferential gap between the rollers 3, so that two adjacent rollers 3 are set in contact.

[0041] Both the first elastic body and the second elastic body include a connecting block 2-4 and an elastic plate 2-5, the connecting block 2-4 connects the beam body 2-3 and the elastic plate 2-5, and the two ends of the elastic plate 2-5 extend Out of the connection block 2-4, the two ends of the elastic plate 2-5 are fixedly equipped w...

Embodiment 2

[0047] Such as Image 6 As shown, the difference between Embodiment 2 and Embodiment 1 is only that the elastic main beam has a single baffle plate with several rollers 3 evenly distributed between the first guide surface 2-1 and the second guide surface 2-2. 1 circle.

Embodiment 3

[0049] Such as Figure 7 with Figure 8 Compared with Embodiment 1, the shown embodiment 3 differs only in that: in order to realize that the rollers 3 are fully filled between the first guide surface 2-1 and the second guide surface 2-2, the outer lock 4 on the cage The number of -1 is consistent with the number of rollers 3 and corresponds one by one. The number of inner locks 5-1 on the cage is half of the number of outer locks 4-1, and the number of inner locks 5-1 is used to limit two The roller 3, the outer lock 4-1, the first limiting pocket 6 and the second limiting pocket 7 are all used to limit a single roller 3. Use two baffles 1 to axially fix the roller 3 to reduce the axial force during the operation of the bearing. The outer side of the roller 3 is limited by the outer lock 4-1 to prevent it from falling out of the pocket hole. The inner side of the child 3 is limited by the inner lock 5-1 to prevent it from falling out of the pocket, wherein the inner lock 5-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com