Anti-reversed integrated cross circular-groove gas fuel spraying and mixing device

A gas fuel, injection mixing technology, applied in the direction of fuel supply device, charging system, combustion engine, etc., can solve the problem of reverse leakage of the injection valve, and achieve the goal of increasing the intake air volume, increasing the flow area, and increasing the flow coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

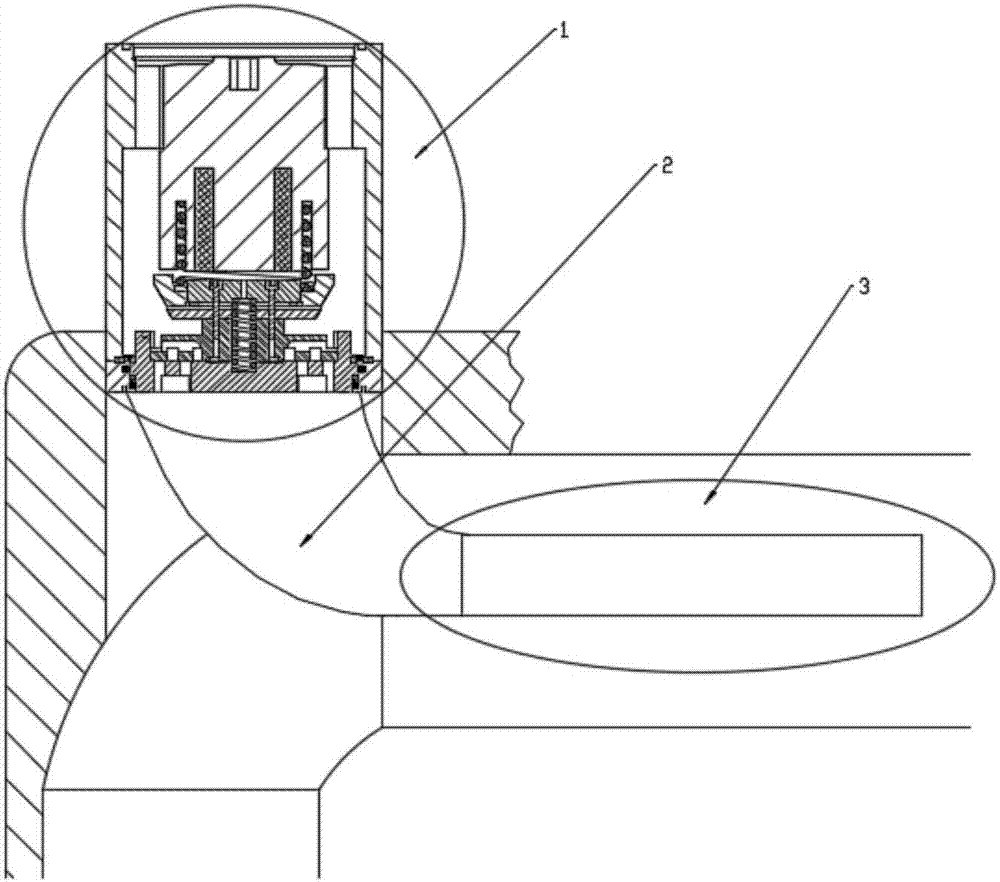

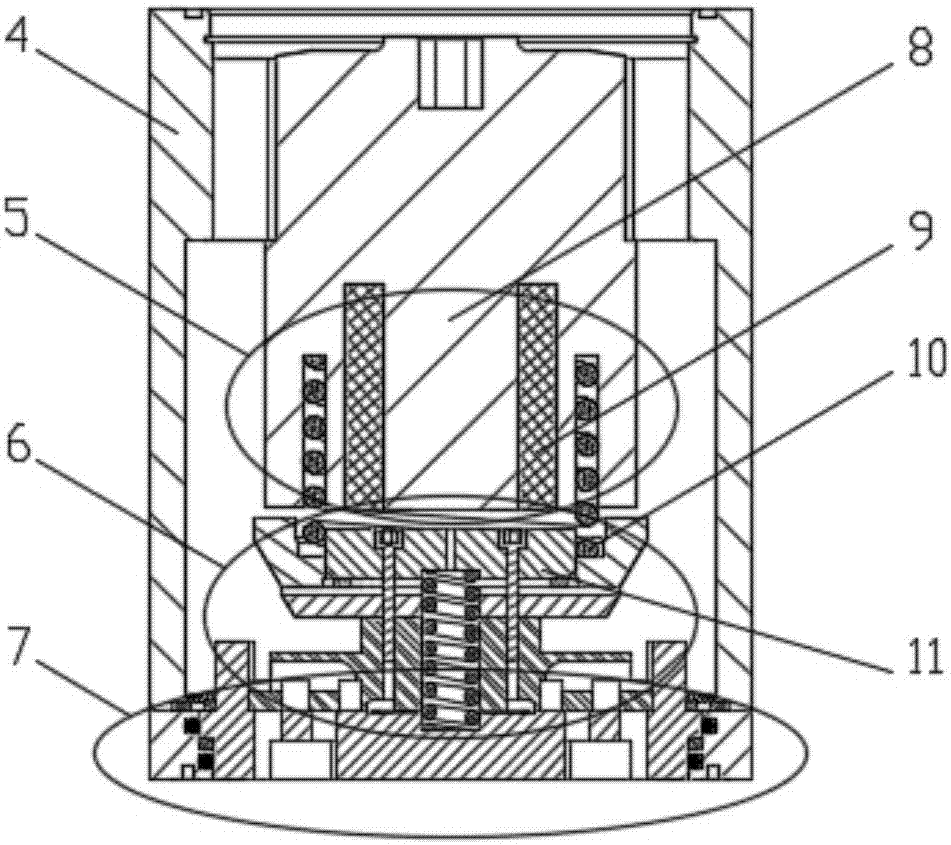

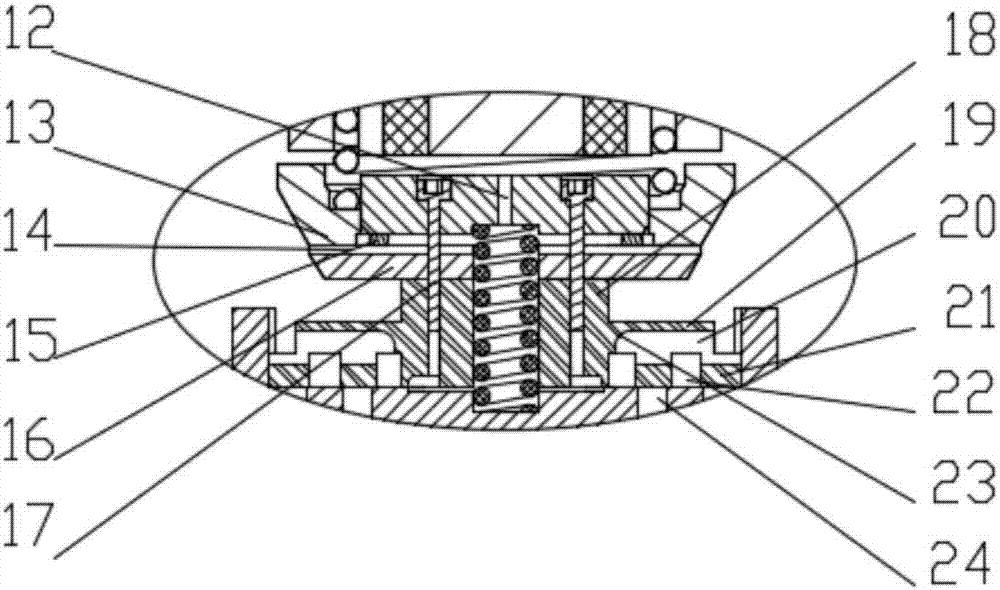

[0021] combine Figure 1-7 , an anti-reverse integrated cross-ring groove gas fuel injection mixing device in the present invention is divided into a fuel injection valve 1, a connecting gas cover 2 and a fuel diffusion pipe 3. The fuel injection valve is mainly composed of four parts: a valve body 4, an electromagnet 5, a valve core assembly 6, and a floating valve seat 7. The electromagnet 5 is connected with the valve body 4 through the upper screw thread. The electromagnet 5 is mainly composed of an iron core 8 and a coil 9. Both sides of the iron core 8 are provided with annular grooves for arranging a return spring 10 . A valve core assembly 6 is arranged below the electromagnet. Below the valve core assembly 6 is a floating valve seat 7 structure. The floating valve seat 7 and the valve body 4 are not fixed with screws, and the connection between the two i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com