System and method for testing of seal materials

a technology of sealing materials and testing methods, applied in the direction of machine parts testing, structural/machine measurement, instruments, etc., can solve the problems of leakage between the two mating flanges, the effect of the sealing member may diminish additionally, and the sealing force of the sealing member may also decreas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]Reference will now be made in detail to specific aspects or features, examples of which are illustrated in the accompanying drawings. Wherever possible, corresponding or similar reference numbers will be used throughout the drawings to refer to the same or corresponding parts.

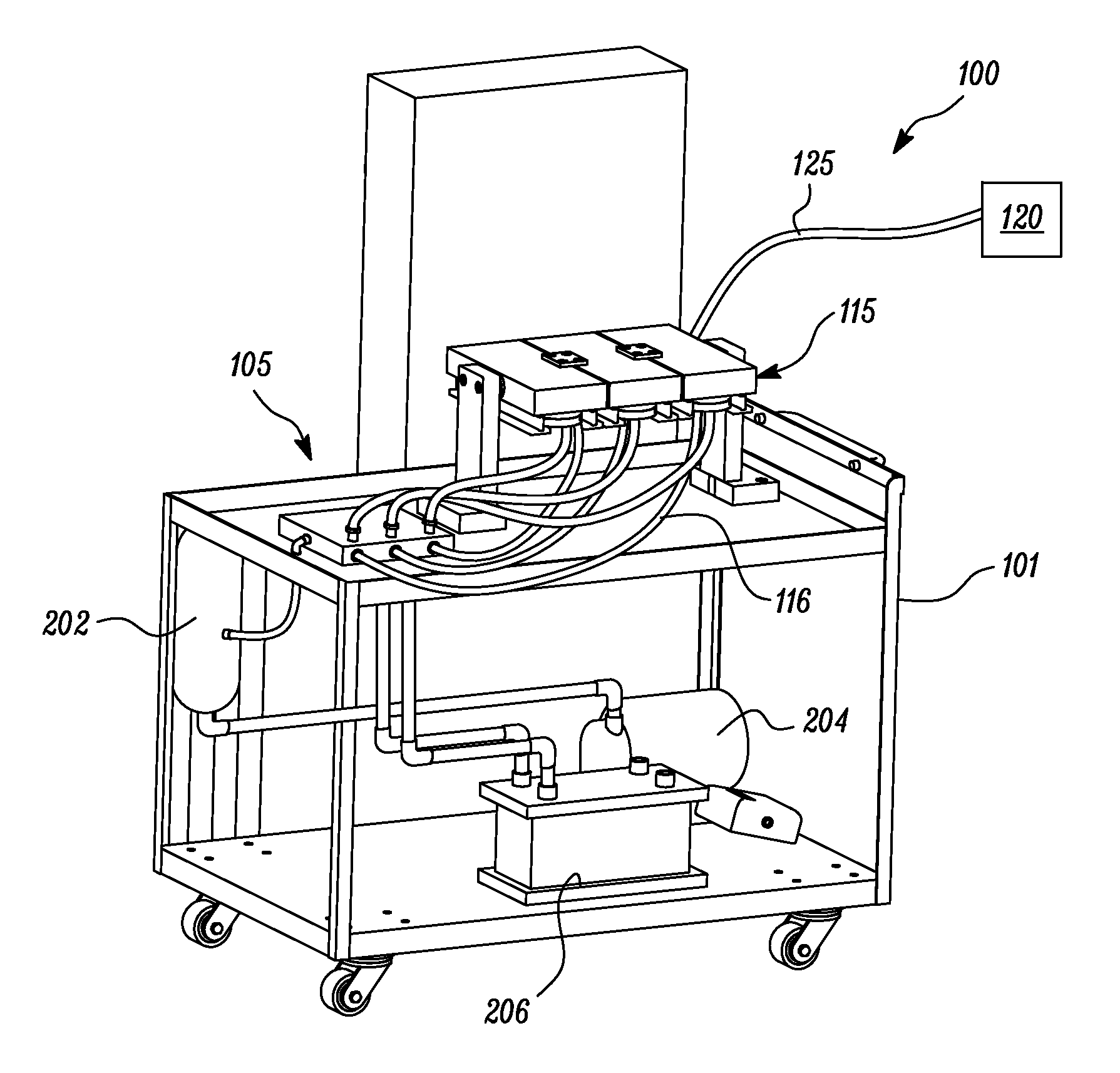

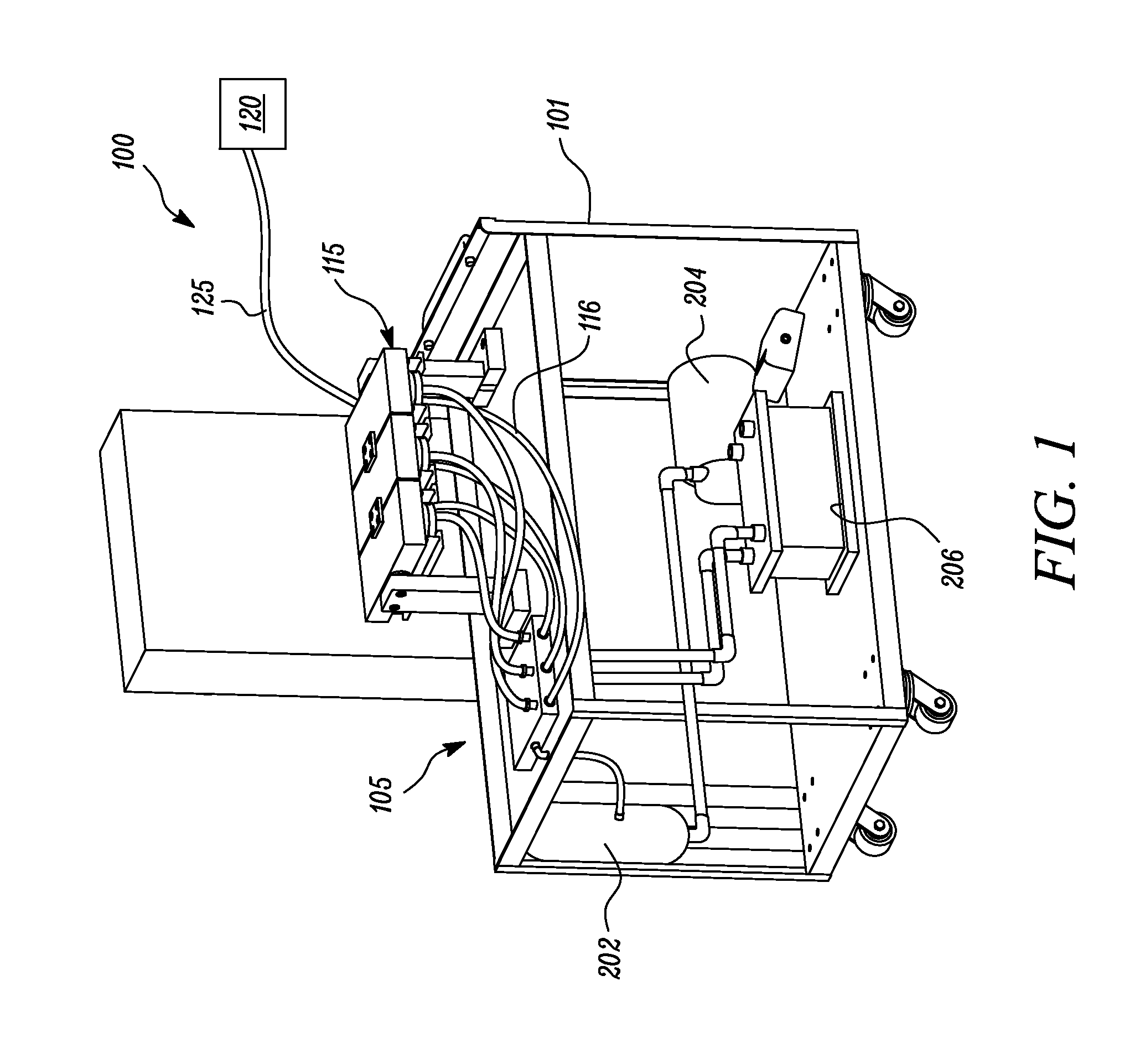

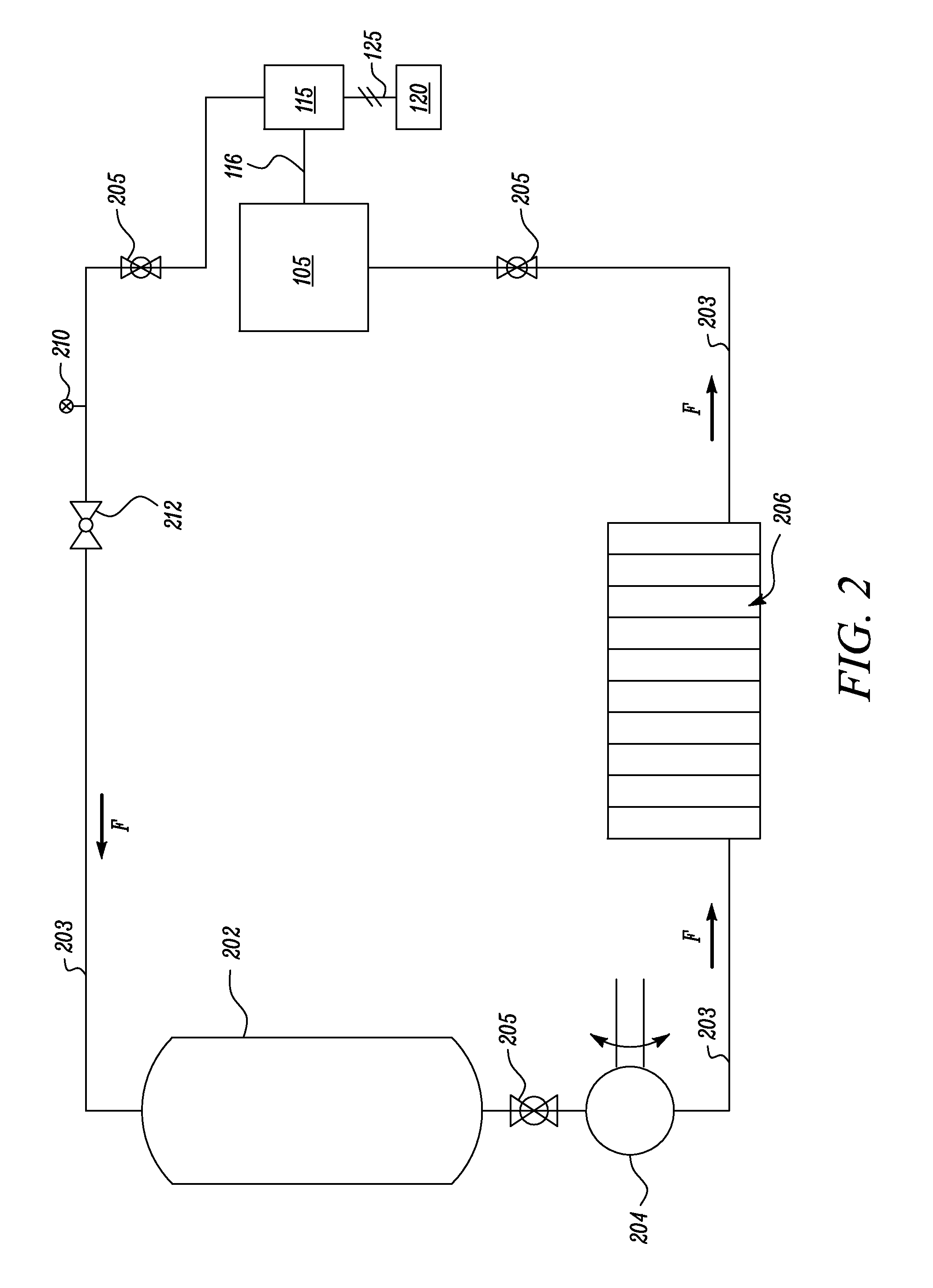

[0015]FIG. 1 illustrates an exemplary test apparatus 100, according to one embodiment of the present disclosure. The test apparatus 100 includes a test bench 101, a fluid manifold 105 placed on the test bench 101. FIG. 2 is an exemplary hydraulic circuit associated with the test apparatus 100. Referring to FIGS. 1 and 2, the fluid manifold 105 is configured to transfer a volume of an aging fluid, such as a coolant. Alternatively, the fluid may include a fuel, oil, an emulsion, and the like depending upon a test to be conducted by the test apparatus 100. The fluid manifold 105 is in communication with a testing fixture 115. In an embodiment, the fluid manifold 105 is coupled to the testing fixture 115 via ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com