Shield tunneling machine articulation mechanism seal performance test device and test method

A hinged mechanism and sealing performance technology, applied in the sealing of the hinged mechanism between the rear shield, the middle shield, and the front shield, can solve the problem of affecting the sealing performance of the hinged mechanism, the life of the sealing ring, the test of the sealing performance and life of the sealing ring, and the impact of the sealing ring Sealing performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

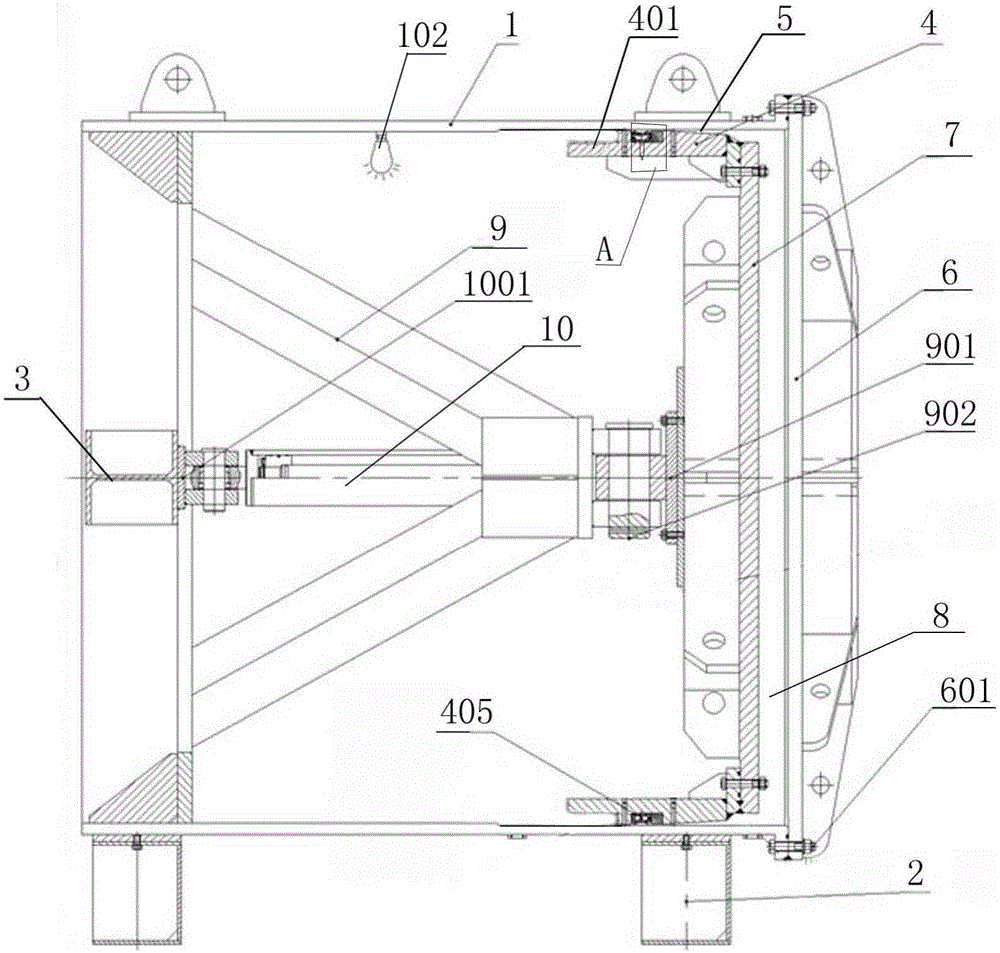

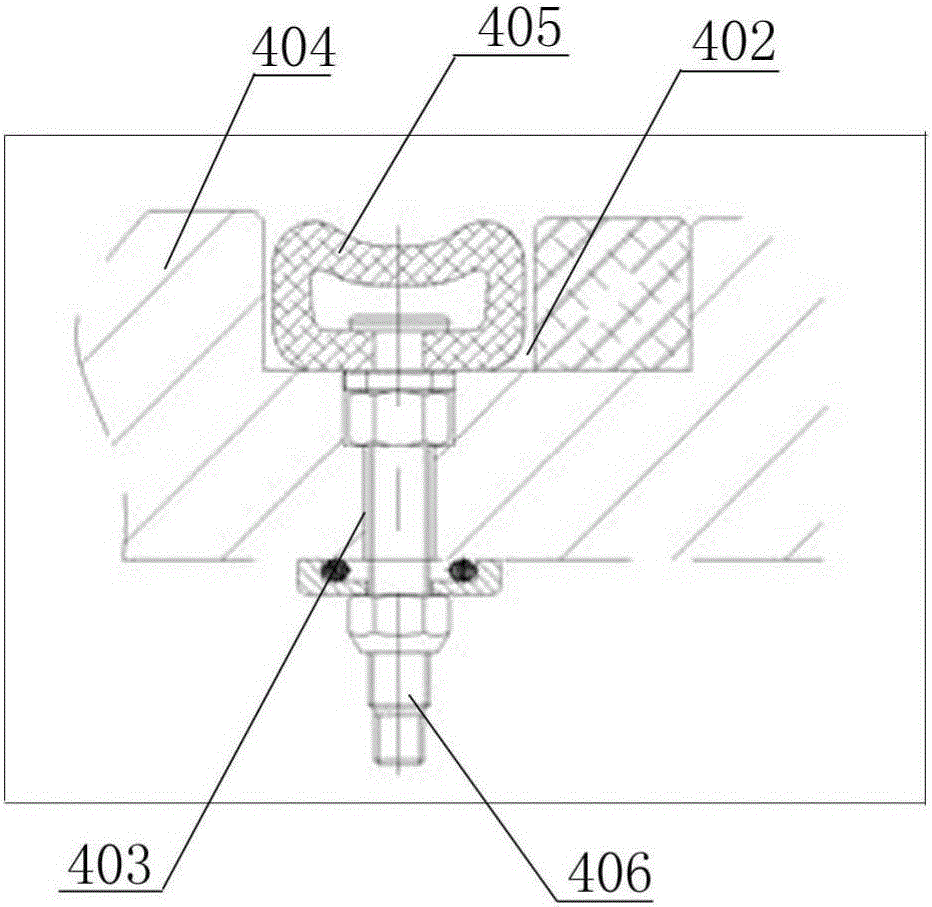

[0039] Please also refer to figure 1 and figure 2 , figure 1 It is a longitudinal sectional view of Embodiment 1 of the sealing performance test device of the shield machine hinge mechanism of the present invention, figure 2 yes figure 1 Enlarged view of part A in .

[0040] The sealing performance test device of the shield machine hinge mechanism of the present invention includes: an outer cylinder 1 and a mounting frame 2, the outer cylinder 1 is fixed on the mounting frame 2, and the rear end of the outer cylinder 1 is provided with a supporting beam 3; it also includes a hinged sealing ring 4, The hinged seal ring 4 is coaxially sleeved on the front end of the outer cylinder 1 , and a gap 5 is formed between the outer wall of the hinged seal ring 4 and the inner wall of the outer cylinder 1 , and the gap 5 constitutes a turning space for the hinged seal ring 4 relative to the outer cylinder 1 . The front end of the hinged sealing ring 4 is tapered, and the diameter o...

Embodiment 2

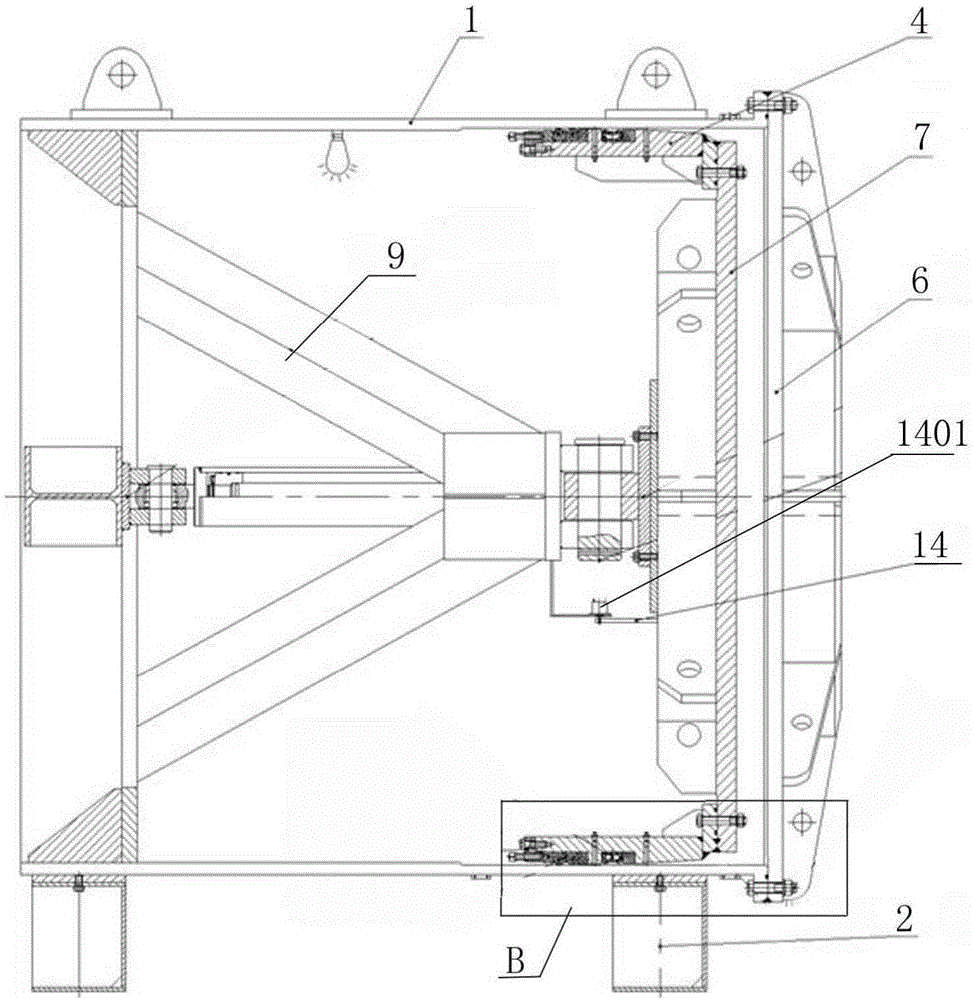

[0046] Please also refer to Figure 3 to Figure 6 , image 3 It is a longitudinal sectional view of Embodiment 2 of the sealing performance test device of the shield machine hinge mechanism of the present invention, Figure 4 yes image 3 Enlarged view of part B in, Figure 5 It is a cross-sectional view of Embodiment 2 of the sealing performance test device of the shield machine hinge mechanism of the present invention, Figure 6 It is a structural schematic diagram of the joints on the pressure storage tank and the first baffle in Example 2 of the sealing performance test device for the shield machine hinge mechanism of the present invention.

[0047] Embodiment 2 is a further improvement to Embodiment 1. In Embodiment 2, the rear end of the hinged sealing ring 4 is provided with an adjustment assembly (such as Figure 4 shown), the adjustment assembly includes a bar 11 that is in contact with the rear end of the elastic sealing ring to be tested, a pressure block 12 fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com