Sealing performance testing machine for sealing ring of bearing

A bearing sealing and ring sealing technology, applied in the field of bearing sealing performance testing, can solve the problems of inability to test and study the bearing sealing ring, inability to simulate the performance of the sealing ring, inconvenient replacement, etc., to save the test cost and occupy a small space. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

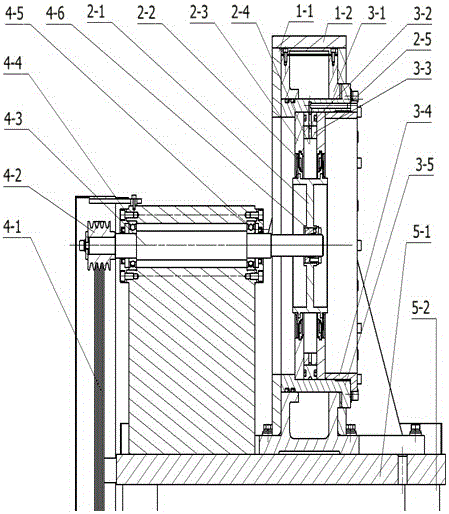

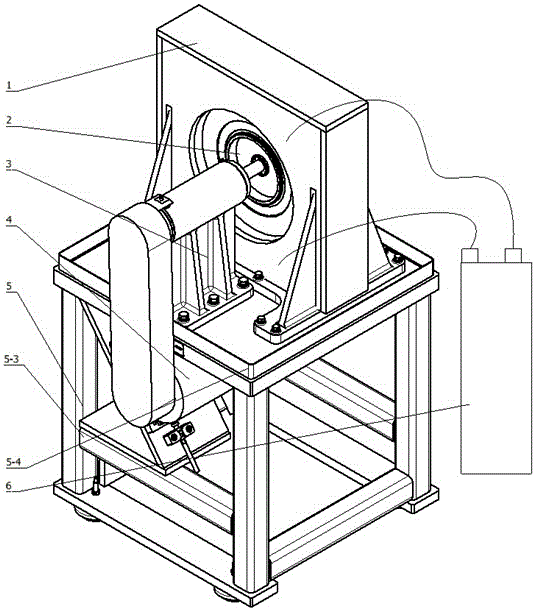

[0013] see figure 1 and figure 2 , the sealing performance testing machine of the bearing sealing ring proposed by the present invention comprises a thermal insulation part 1, a tooling part 2, a supporting part 3, a driving part 4, a body part 5 and a high and low temperature integrated machine 6, and is characterized in that the workpiece in the driving part 4 One end of the shaft 4-3 is connected with a pulley 4-2, and the other end is connected with the tooling wheel 2-1 in the tooling part 2 through the keyless bushing 4-6, and the two bolts at the outer ends of the keyless bushing 4-6 are tightened , can achieve the purpose of quickly replacing the tooling wheel 2-1, the workpiece shaft 4-3 is located inside the shaft box above the support body 3-1 in the support part 3, and is fixed on the shaft box by two sets of the same working bearing 4-5 Inside, the workpiece shaft 4-3 can rotate inside the shaft box, and the two ends of the workpiece shaft 4-3 are pressed throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com