Sealing system having leakage sensing function

a technology of leakage sensing and sealing system, which is applied in the direction of fluid loss/gain rate measurement, fluid tightness measurement, instruments, etc., can solve the problems of high manufacturing cost, difficult maintenance, and complex structure of mechanical seal type rotary sealing device, so as to maximize the time of use of sealing member, quick and accurate sense of sealing member, and the effect of leakage acciden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053]Reference will now be made in detail to embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to the like elements throughout. The embodiments are described below in order to explain the present invention by referring to the figures.

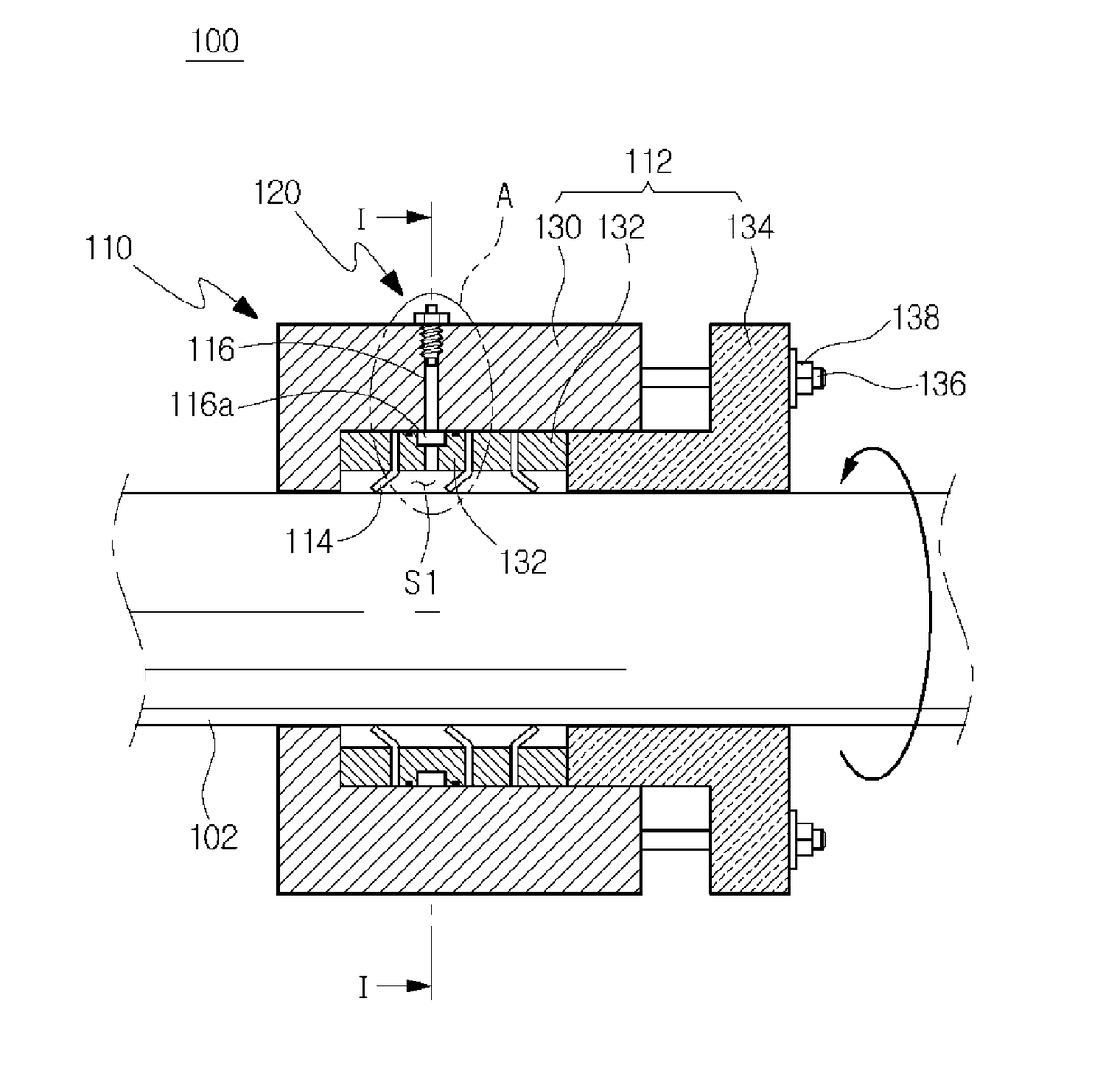

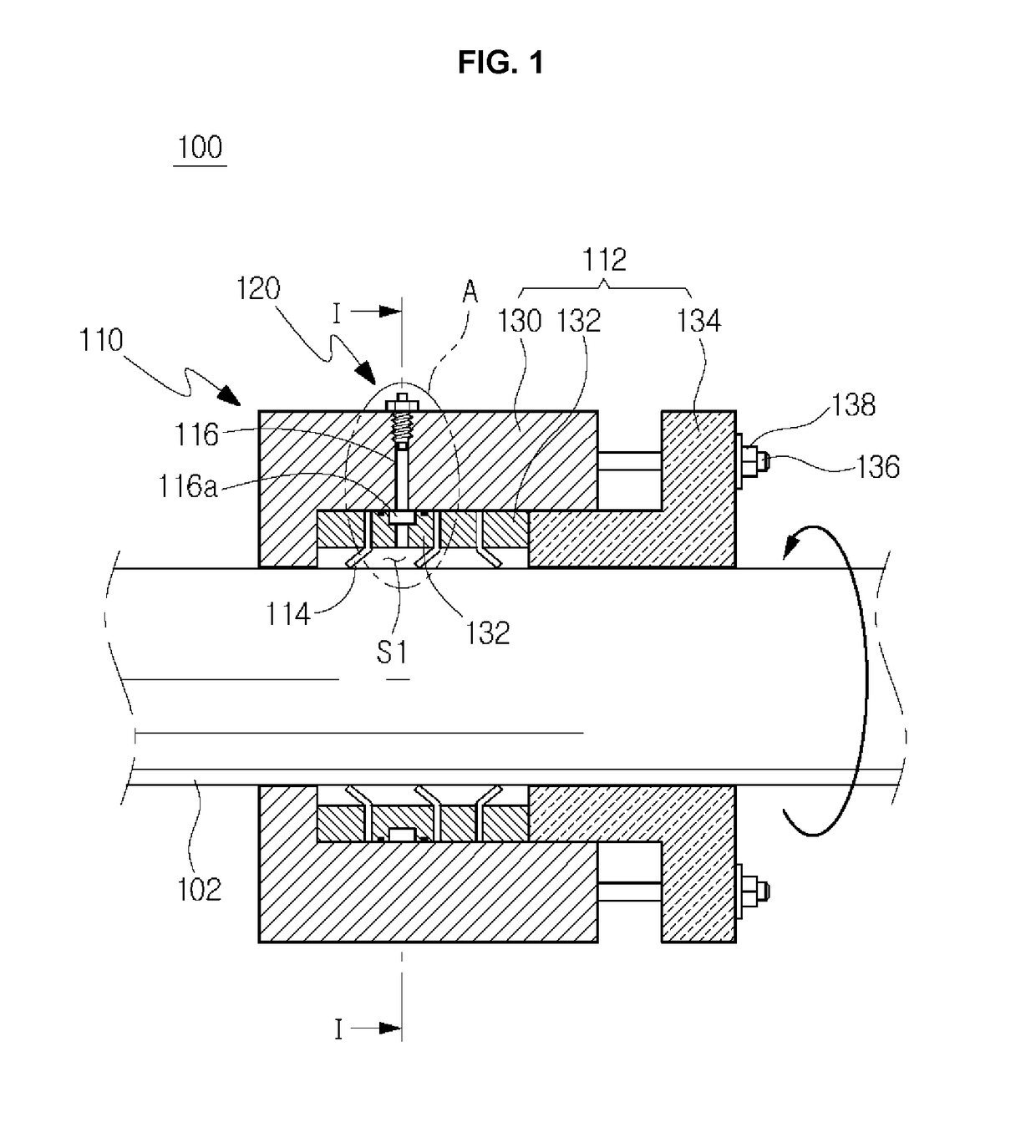

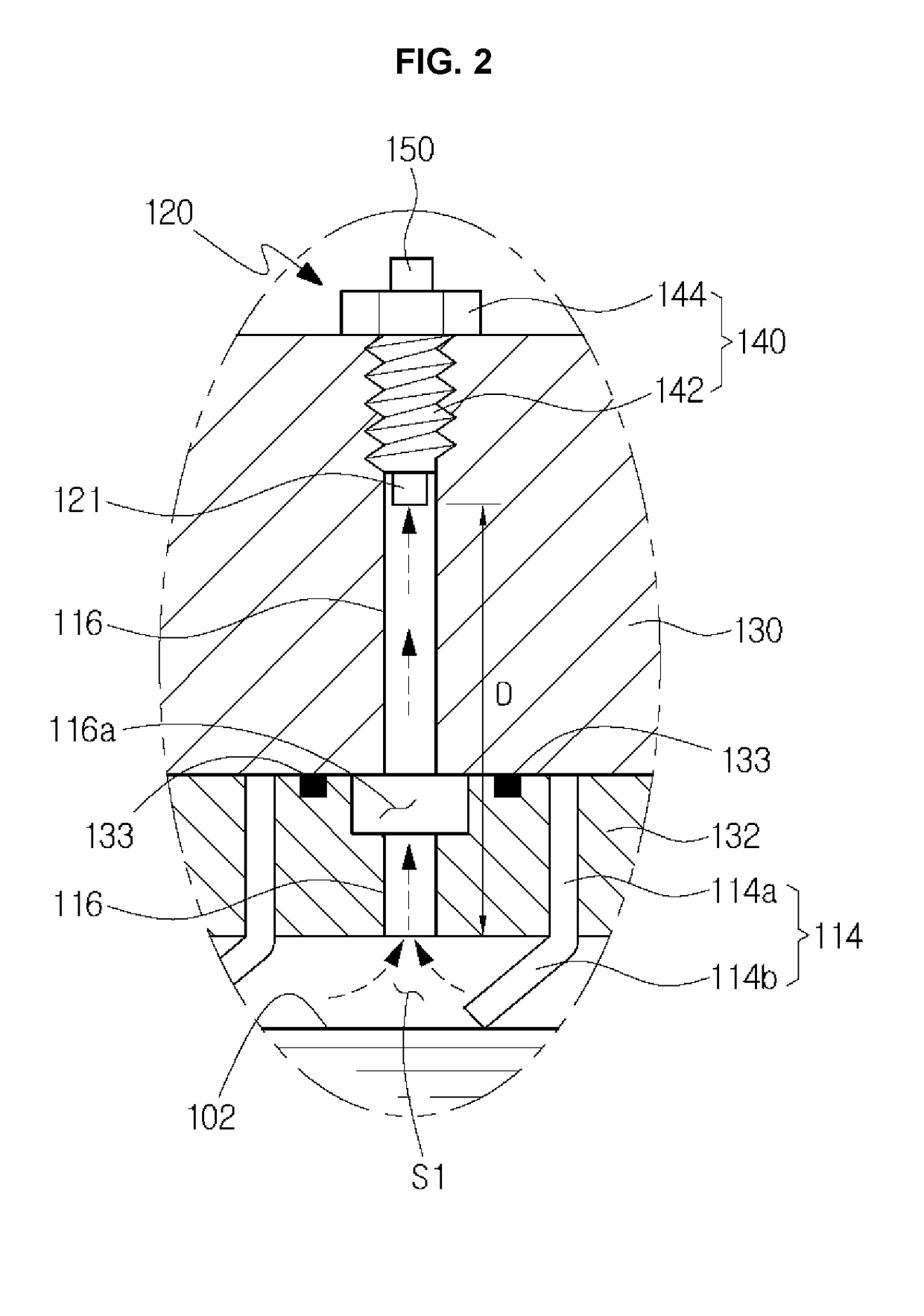

[0054]FIG. 1 illustrates a sealing system 100 having a leakage sensing function according to an embodiment. FIG. 2 is an enlarged view of a portion A of FIG. 1, and FIG. 3 is a cross-sectional front view cut along a line I-I of FIG. 1.

[0055]Referring to FIGS. 1 through 3, the sealing system 100 having a leakage sensing function includes a sealing device body 110 and a leakage sensing unit 120.

[0056]In general, mechanisms such as a stirrer, a reactor, and a mixer are widely used in the fields of petrochemistry, fine chemistry, medical science, pharmacy, and food. The mechanisms may each include a drive shaft that performs a rotary motion or a reciprocating rectilin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com