Satellite element service life evaluation method based on aging test data before assembly

A technology of test data and evaluation method, applied in the field of life evaluation of satellite components, can solve the problems of unpredictable on-site reliability, expensive implementation, and inaccurate reliability prediction results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0170] In the following, the present invention will be further described in detail in conjunction with the accompanying drawings and a life evaluation case of a typical satellite component.

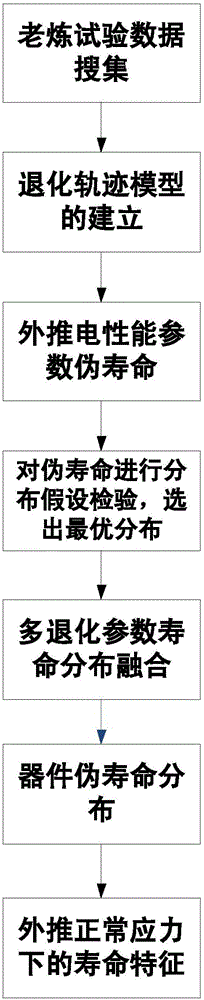

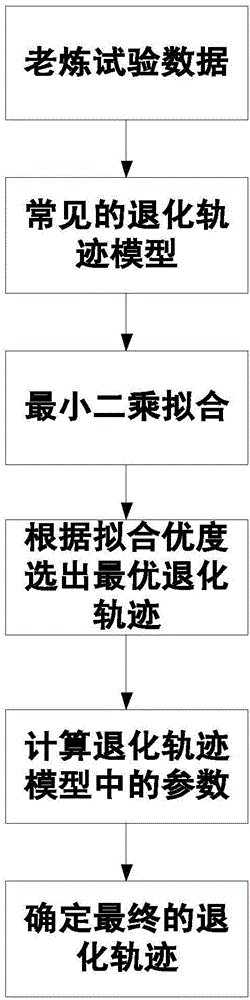

[0171] The invention relates to a method for evaluating the life of satellite components based on aging test data before installation. The specific steps are as follows:

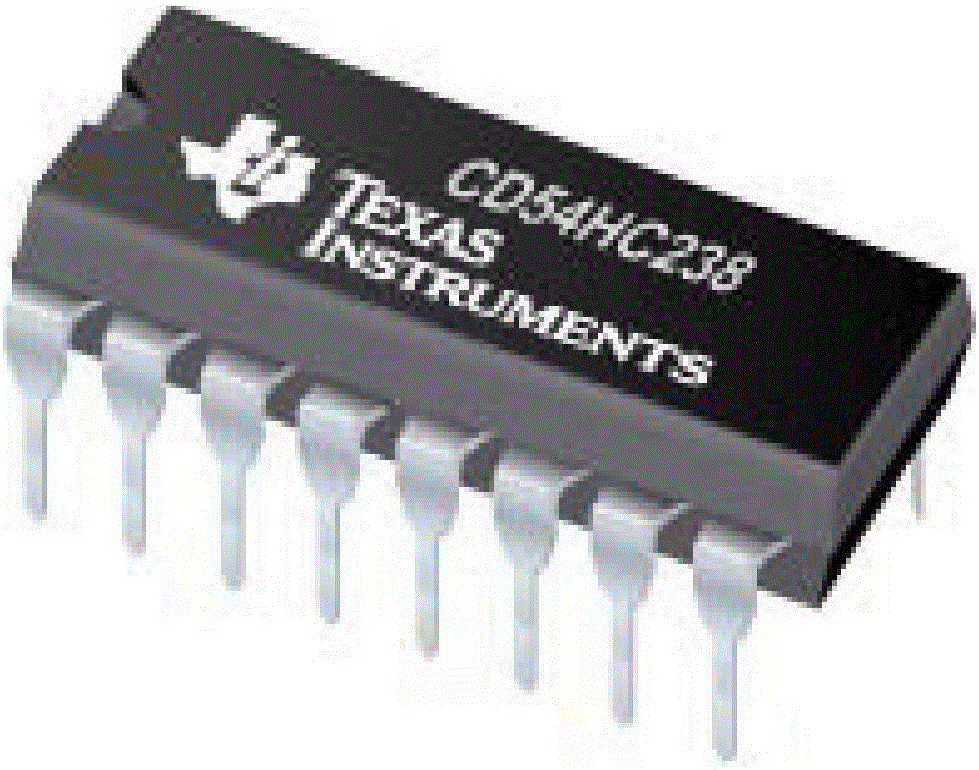

[0172] Step 1: Data Collection

[0173] The selected model is CD54HC238 typical star components, such as figure 2 shown. The burn-in test data is collected and organized as follows: a total of 124 components of this type have been subjected to burn-in tests, and the electrical performance parameters of the devices are tested at time 0, 48h and 96h respectively. There are 4 performance parameters, and the data obtained from the time 0, 48h and 96h tests are shown in Table 3 to Table 5. Due to the large number of devices, the first five devices are used as an example. If there is no explanation, the following are all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com