Accelerated degradation test prediction method based on fuzzy theory

A technology of accelerated degradation test and fuzzy theory, applied in the field of life prediction, which can solve problems such as the inability to describe engineering practice and the ambiguity of performance failure criteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

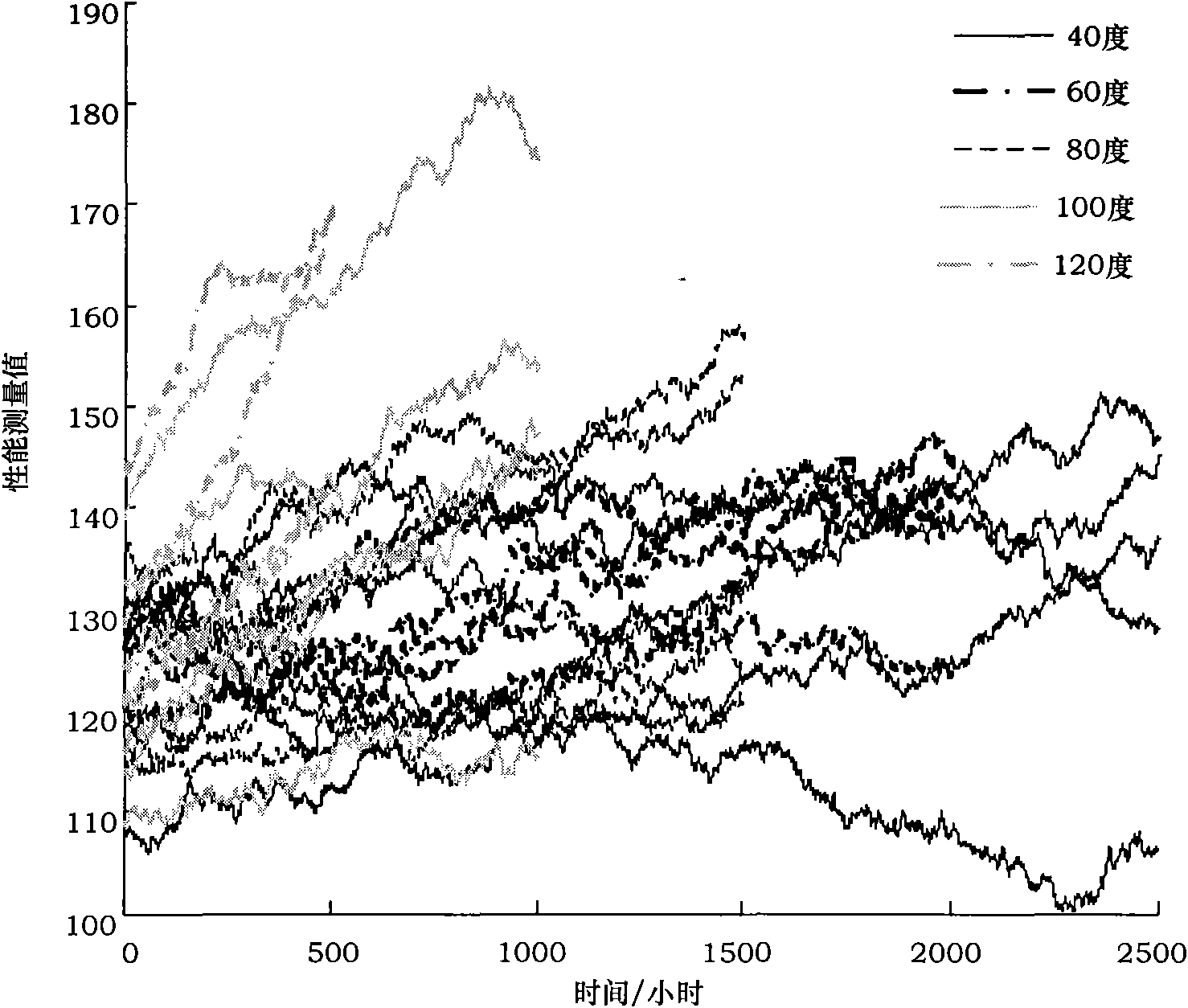

[0128] The method of the present invention adopts the Monte Carlo simulation method to verify its correctness.

[0129] Suppose there are 25 products equally divided into 5 groups for CSADT at 5 temperature levels. The test parameters are shown in Table 1.

[0130] Table 1 CSADT test parameters

[0131]

[0132]

[0133] In the simulation process, it is assumed that the product performance degradation process obeys the drift Brownian motion, and the drift coefficient d(s) is the Arrennius model. At this time, the stress s is written as the absolute temperature T, then d(T)=exp(A-B / T). Then the performance degradation drift Brownian motion of the product can be written as:

[0134] Y(t)=σB(t)+exp(A-B / T) t+y 0

[0135] Among them, suppose A=9000, B=4800, diffusion coefficient σ=0.25, initial value y 0 = 124. Then the performance degradation curve of the product is obtained by simulation as follows: image 3 shown. Depend on image 3 It can be seen that the black s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com