Asymmetric progressive safety gear

A safety gear, progressive technology, applied in the field of U-shaped leaf spring asymmetric progressive safety gear, can solve the problems of heavy weight and large volume, and achieve the effects of light weight, small volume, and improved safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

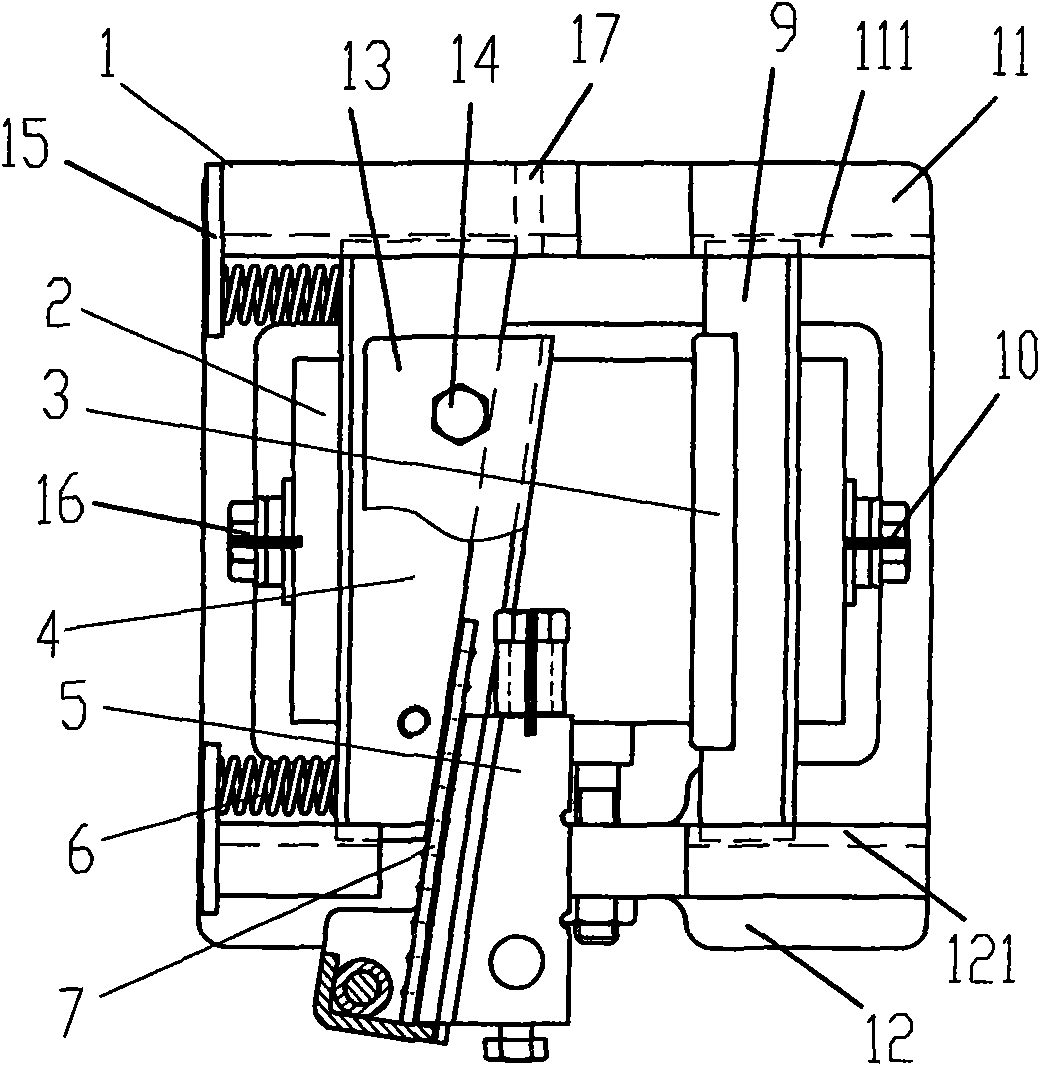

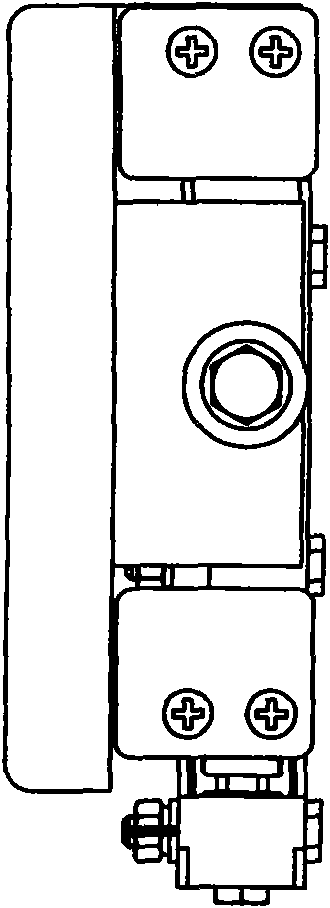

[0071] Embodiment one: if Figure 1-6 As shown, the safety gear includes a clamp body 1, a U-shaped leaf spring 2, a friction plate 3, a moving wedge 4, a sliding wedge 5, a return spring 6, a roller row 7, and a slider 9.

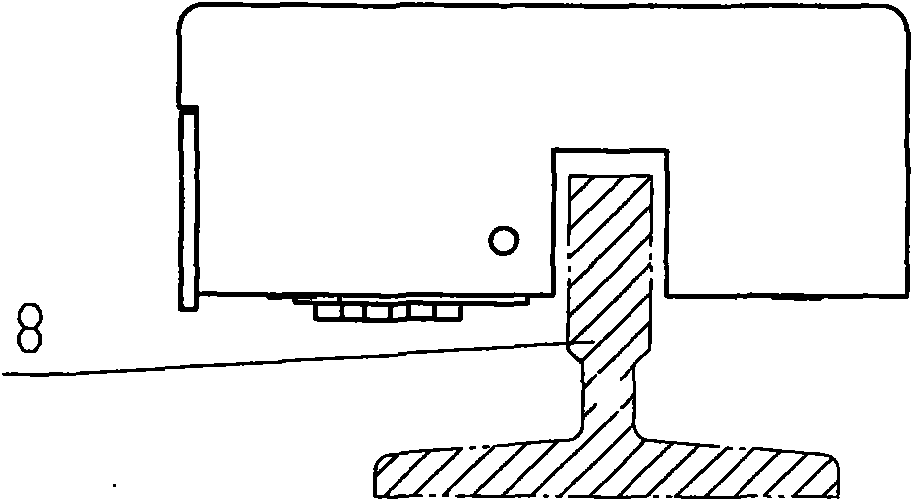

[0072] The pliers body 1 is fixedly installed on the elevator car or the counterweight, and the pliers body 1 is hollowed out to reduce its weight and save manufacturing cost. The upper and lower sides 11, 12 of the pliers body 1 respectively form a gap, and the gap on the lower side 12 is larger than the gap on the upper side 11. The elevator guide rail 8 passes through two gaps longitudinally, and the elevator guide rail 8 is not a part of the safety gear.

[0073] The top 11 and the bottom 12 of the pliers body offer slideways 111, 121, and the slideways 111, 121 correspond up and down. A slider 9 is slidably inserted between the upper and lower slideways 111 and 121 on the right side of the notch, and the inner surface of the slider 9 (that is, the s...

Embodiment 2

[0083] Embodiment two: if Figure 7-10 As shown, the structure of this embodiment is arranged symmetrically with that of Embodiment 1.

Embodiment 3

[0084] Embodiment three: as Figure 11-14 As shown, the return spring 6 is assembled on the right side of the pliers body 1, and the type of the return spring at this time is an extension spring. One end of a spring 6 is respectively fixed on the upper and lower parts of the outer surface of the slide block 9 , and the other end of the spring 6 is fixedly connected with the pliers body 1 .

[0085] Other content of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com