Wiper arm

A technology of wiper arm and fixing parts, applied in the field of wiper arm, can solve the problems of the loss of the support force of the wiper arm, the shortening of the spring length, etc., and achieve the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

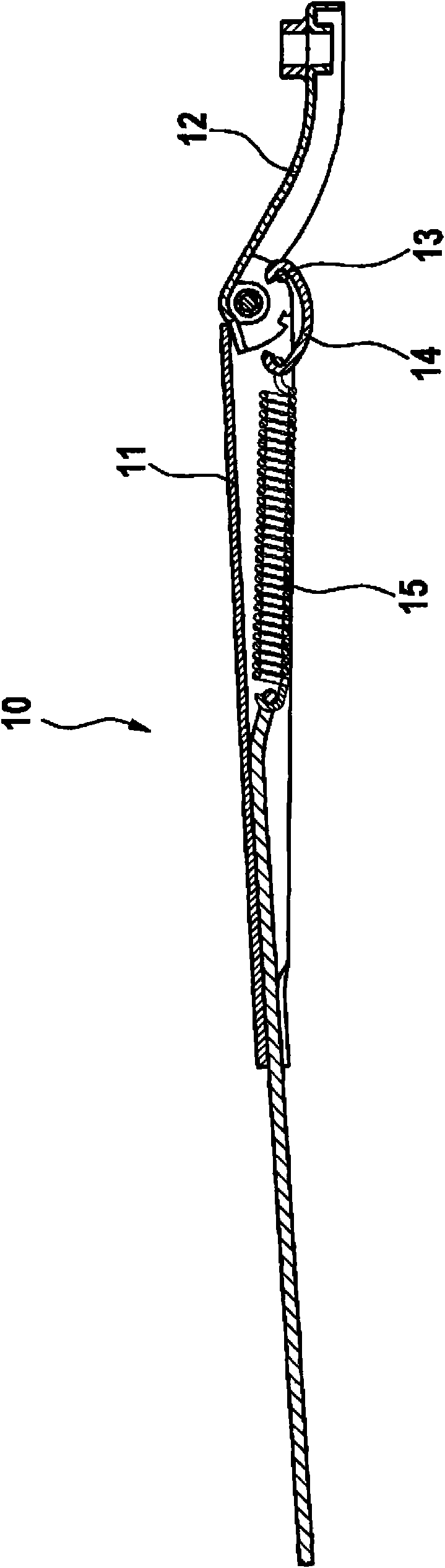

[0027] figure 1 Wiper arm 10 is shown with hinged part 11 and fastening part 12 . The articulation part 11 is articulated on the fastening part 12 , so that a wiper blade, not shown in detail here, is pivotably arranged on the wiper arm 10 . In this way, the wiper blade can be pivoted away from the window glass and can be pivoted into engagement on the window glass.

[0028] A C-shaped hook 14 is hung at the bolt bar 13, a spring 15 is hung in the hook, and the spring 15 is hung at the hinge 11 again in the same way.

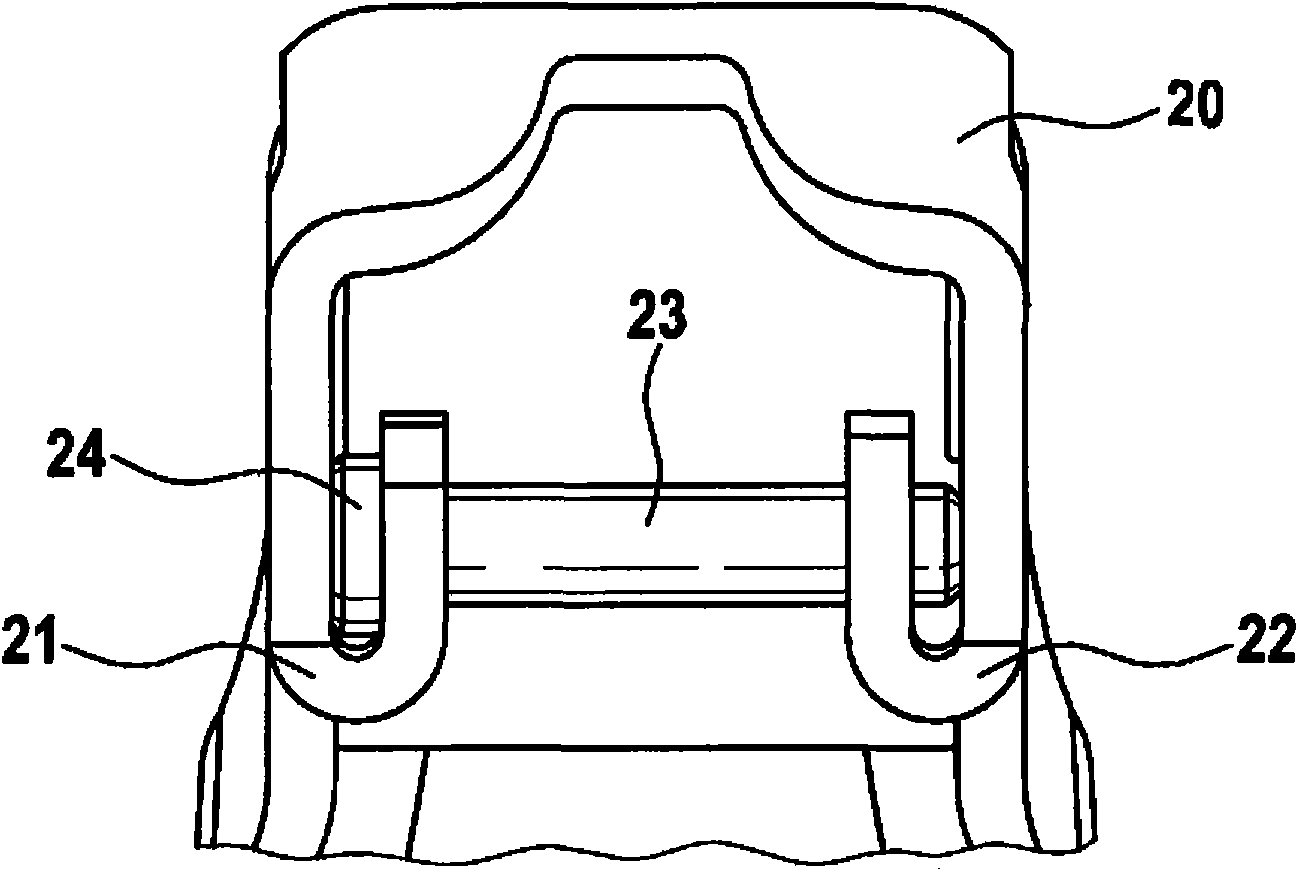

[0029] figure 2 A fastening part 20 with two webs 21 and 22 and a pin 23 is shown. The webs 21 and 22 are bent towards the inside of the fixing part 20 . As a result, the bolt rod 23 has a relatively short length. Due to the relatively short length of the pin 23 , deflections can be reduced and thus a maximum bearing force of the wiper arm 10 can be ensured.

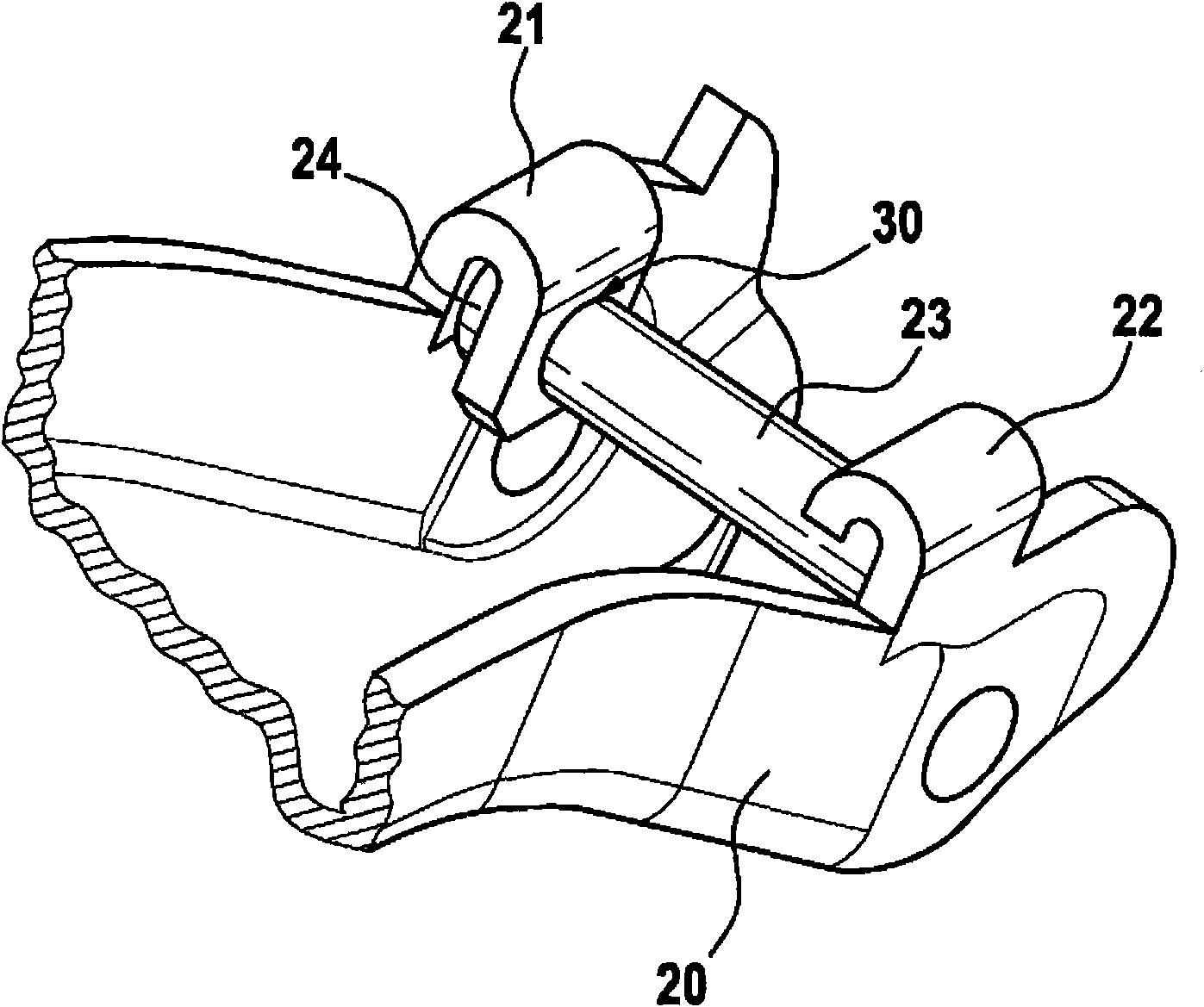

[0030] Tab 21 has a through hole 30 (see image 3 ), the bolt rod 23 passes through the through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com