Method for producing milling grooves in soil and groove wall milling device

A technology of milling device and groove wall, which is applied in excavation, earthmoving machine/shovel, mechanically driven excavator/dredging machine, etc. Daily output, the effect of efficient milling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

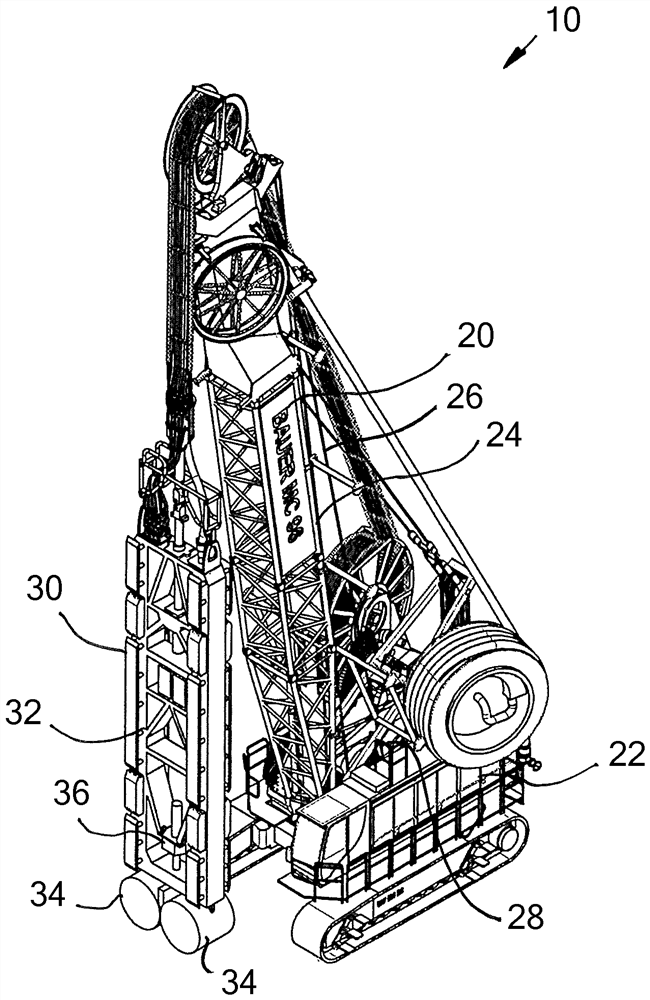

[0026] The slot wall milling device 10 according to the figure has a carrier 20 with a carrier device 22 provided with a crawler running gear. At the carrier device 22, the mast 24 is positioned approximately vertically pointing, and the carrier cable 26 is guided on the mast head of the mast.

[0027]At the free end of the carrying cable 26, a substantially known slot wall milling cutter 30 and a scaffold-like milling cutter frame 32 are suspended. The carrier cable 26 is connected to the slot wall mill 30 at the upper end thereof. The other end of the load-carrying cable 26 is led to the only sketched winch 28 at the load-carrying device 22 . The slot wall milling cutter 30 can be lifted and lowered vertically by means of the winch 28 .

[0028] A total of four milling wheels 34 are respectively arranged in pairs at the lower end of the milling cutter frame 32 of the slot wall milling cutter 30 , as shown only schematically in the figures. The milling wheel 34 can be brou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com