A reinforced coil spring

A tube reel, reinforced technology, applied in the direction of coil springs, springs/shock absorbers, mechanical equipment, etc., can solve the problems of coil springs not tightening, coil spring mechanical fatigue, time-consuming and labor-intensive pulling of tubes and wires, etc. Achieve the effects of enhanced tightening force, low production cost and good overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

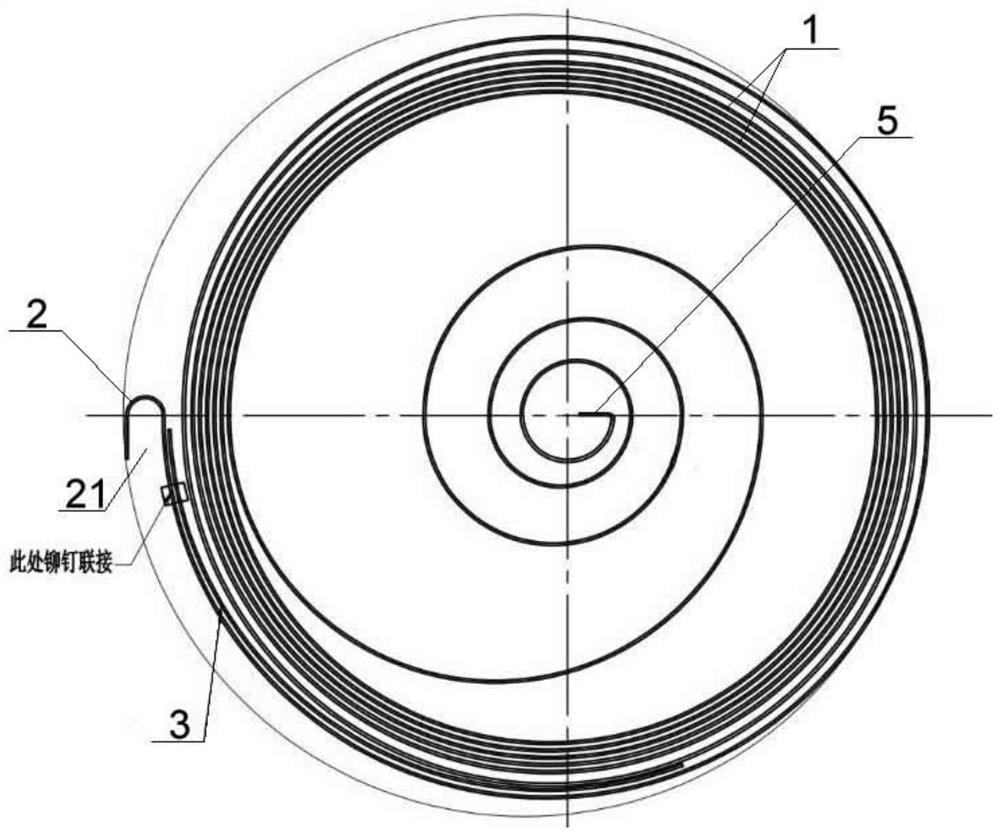

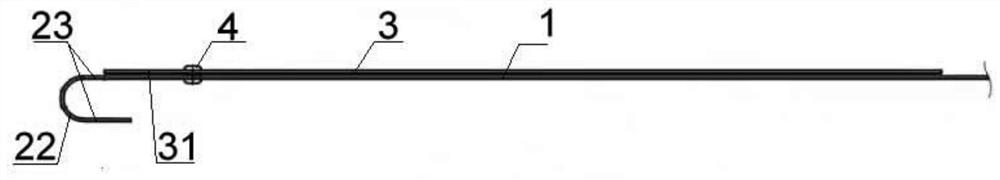

[0020] Example 1: refer to the attached Figure 1-Figure 2 . A reinforced coil spring, comprising a coil spring 1 formed by a coil spring sheet, the outer end of the coil spring 1 is bent to form an ear hook 2, and the opening 21 of the ear hook 2 is located in the outermost ring On the outside of the coil spring, the inner side of the outermost coil spring is provided with a piece of spring steel sheet 3 and the outer end of the spring steel sheet 3 is fixedly connected with the outermost coil spring. The inner end is located between the outermost coil spring and the secondary outer coil; that is, only the outer end of the spring steel sheet 3 is fixedly connected to the outermost coil spring; The length is a quarter of the length of the outermost coil spring. The setting of the length, width and thickness of the spring steel plate 3 plays a role in thickening the outermost coil spring, so that the coil spring can be retracted during the retraction process. The outermost co...

Embodiment 2

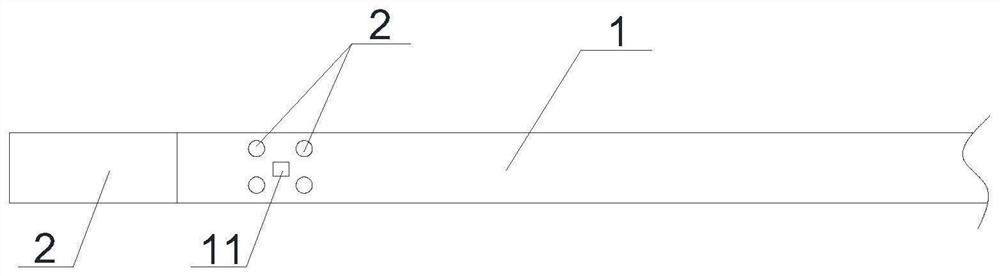

[0023] Example 2: On the basis of Example 1, refer to the attached Figure 3-Figure 5 . The spring steel sheet 3 and the coil spring are fixedly connected by one or more rivets 4. The spring steel sheet 3 is provided with a plurality of first rivet holes, and the back of the spring steel sheet 3 is provided with positioning protrusions. The outermost coil spring is provided with a plurality of second rivet holes, and the outermost coil spring is provided with positioning holes 11 and the positioning holes 11 is located between a plurality of second rivet holes, the positioning through hole 11 is a square hole, and the positioning protrusion 32 is square; the size of the square hole matches the size of the square positioning protrusion 32, and the positioning protrusion The first rivet hole on the spring steel sheet 3 and the corresponding second rivet hole on the outermost coil spring sheet are connected one-to-one with the positioning hole 11 concave and convex, so that the ...

Embodiment 3

[0025] Example 3: On the basis of Example 1 and Example 2, refer to the attached Image 6 . The outer end of the spring steel sheet 3 is bent to form an ear hook reinforcement portion 33, and the inner surface of the ear hook reinforcement portion 33 is in close contact with the outer surface of the ear hook 2, and the end of the ear hook reinforcement portion 33 is inwardly rolled. The end and the inner coil end buckle the hook head of the ear hook 2. After the coil spring 1 is formed by the coil spring, the spring steel sheet 3 is riveted with the outermost coil spring, and the outer end surface of the spring steel sheet 3 exceeds The outer end surface of the coil spring is then bent together with the outer end of the spring steel sheet 3 and the outer end of the coil spring by the bending device to form the ear hook 2 and the ear hook reinforcing part 33, and then the ear hook is strengthened. The end of the part 33 is crimped to fasten the hook head of the ear hook 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com