Nut locking structure for screw press

A technology of screw pressure and nut, which is applied in the field of improvement of the anti-loosening structure of the nut, which can solve problems such as easy gaps, loose nuts, and affecting the working efficiency of the press, and achieve the effect of improving the radial bearing capacity and increasing the tightening force

Inactive Publication Date: 2005-01-19

SHANGHAI YUNLIANG FORGING PRESS

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This kind of nut anti-loosening structure, because the cylindrical pin is difficult to bear the large radial force from the press in the working state, so there is a gap between the screw and the nut, which will cause the nut to loosen until it is damaged, which directly affects the pressure of the press. work efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

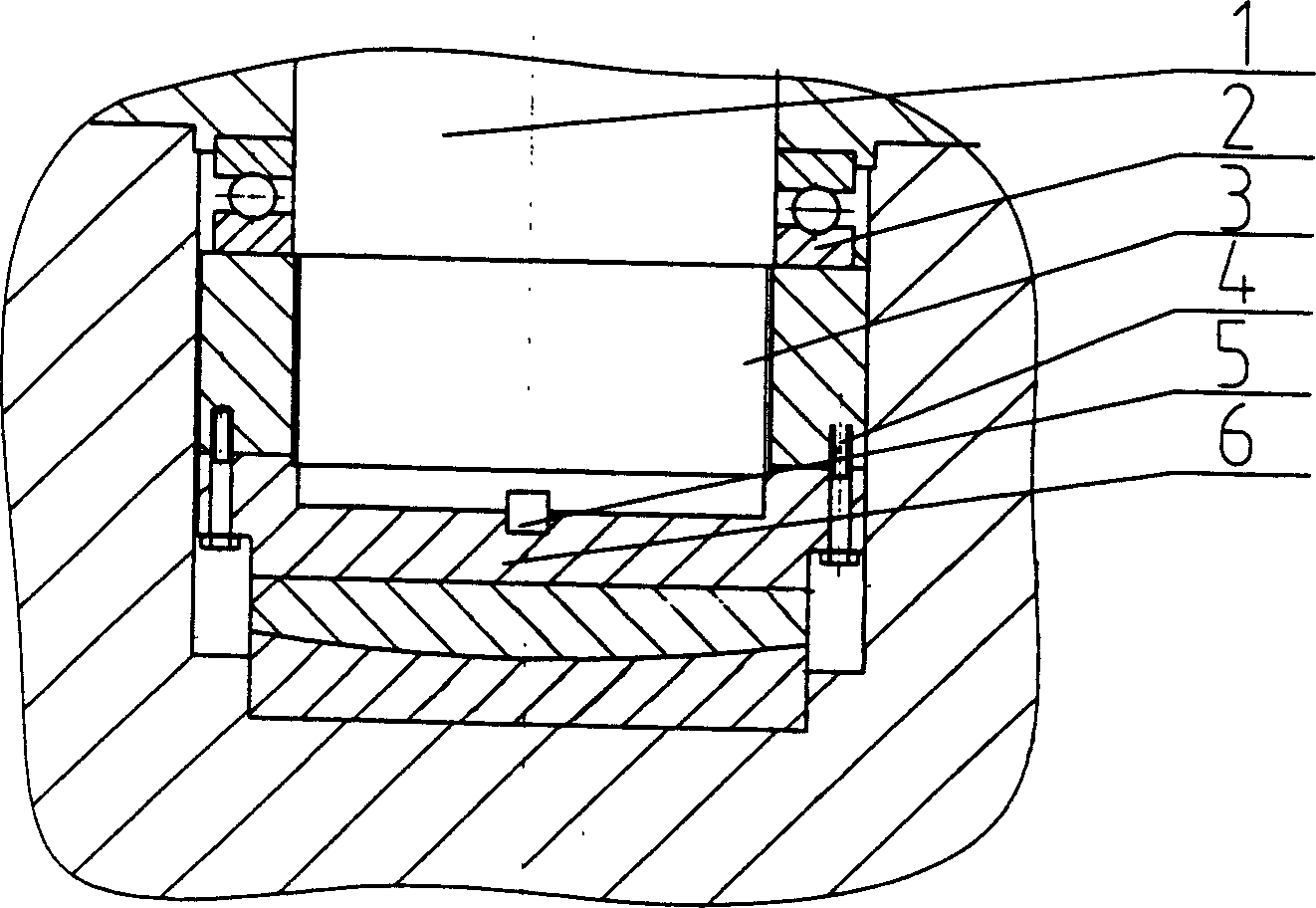

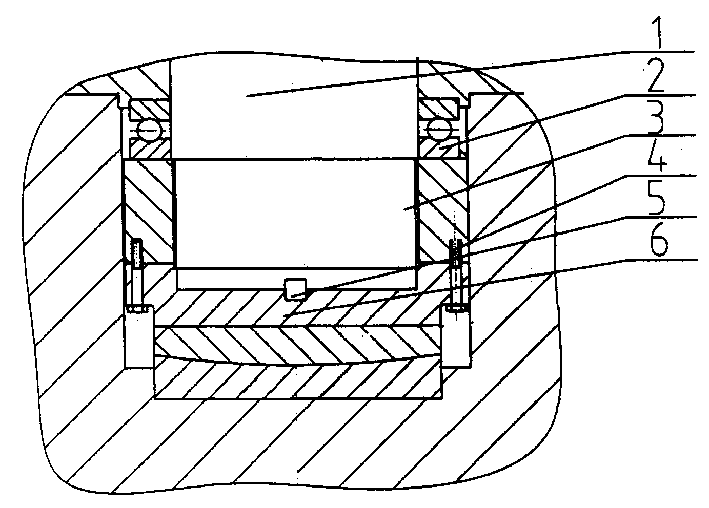

[0008] Screw press nut anti-loosening structure, the bottom of the nut 3 has a keyway, the upper part of the nut seat 6 has a keyway, and the keyway between the nut 3 and the nut seat 6 is fixedly connected by a flat key 5. The nut 3 and the outer edge of the nut seat 6 are fixedly connected by bolts 4 . During use, the screw rod 1 is connected with the nut 3 through the bearing 2 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a nut looseness preventing structure applicable for screw press especially improvement of nut looseness preventing structure in bolt and slide block device of screw press. The nut has a slot on bottom, a slot on upper part of nut seat, and the two slots are connected and fixed by a flat key. The nut and nut seat outer rim are connected and fixed by a bolt. By dividing the nut into two parts of nut and nut seat and replacing the original straight pin by a flat key, the nut radial bearability can be improved greatly.

Description

technical field [0001] The invention relates to a nut anti-loosening structure applied to a screw press, in particular to the improvement of the nut anti-loosening structure in the screw rod and slider device in the screw press. Background technique [0002] Screw rod and slide block device in the existing screw press machine, its structure is, screw rod and nut are threadedly connected, beat a cylindrical pin on screw rod and nut again and fix to prevent loosening. This kind of nut anti-loosening structure, because the cylindrical pin is difficult to bear the large radial force from the press in the working state, so there is a gap between the screw and the nut, which will cause the nut to loosen until it is damaged, which directly affects the pressure of the press. work efficiency. Contents of the invention [0003] In order to overcome the shortcomings of the above-mentioned prior art, the present invention provides an improved anti-loosening structure for screw press ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B30B15/00

Inventor 陆友荣

Owner SHANGHAI YUNLIANG FORGING PRESS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com