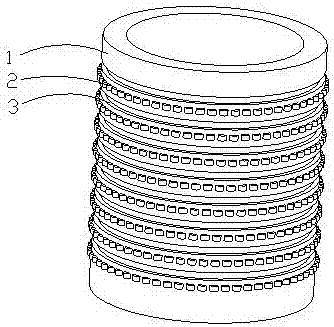

Aluminum cylinder jacket based on jagged surface structure and production method thereof

A surface structure and cylinder liner technology, which is applied to cylinders, cylinder heads, coatings, etc., can solve the difficulty in meeting the requirements of cylinder liner strength, wear resistance and cost, limited bonding force between cast iron cylinder liners and aluminum cylinder blocks, cylinder Overcome the problems of high production cost and achieve the effect of excellent wear resistance, low manufacturing cost and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Step 1, initial co-infiltration

[0048] After the cylinder liner is preheated at 300~350℃, it is sent into the salt bath for salt bath co-infiltration treatment. 100 minutes, wash after salt bath co-infiltration treatment, remove the salt and carbon on the surface of the cylinder liner after co-infiltration;

[0049] Step 2, secondary co-infiltration

[0050] Apply a layer of co-penetration agent evenly on the inner surface of the cylinder liner treated in step 1, then place the cylinder liner on the idler roller of the machine tool, and then insert the plasma torch nozzle into the inner surface of the cylinder liner, and the cylinder liner is driven by the horizontal idler roller The fixed axis rotates, and the plasma torch nozzle makes a reciprocating linear motion, and scans a spiral hardening zone on the inner surface of the cylinder liner to be processed, which completes the secondary co-infiltration process.

[0051] Wherein, the co-infiltration agent consists ...

Embodiment 2

[0054] Step 1, initial co-infiltration

[0055] After the cylinder liner is preheated at 330°C, it is sent into the salt bath for salt bath co-infiltration treatment. After cleaning, remove the salt and carbon on the surface of the cylinder liner after co-infiltration;

[0056] Step 2, secondary co-infiltration

[0057] Apply a layer of co-penetration agent evenly on the inner surface of the cylinder liner treated in step 1, then place the cylinder liner on the idler roller of the machine tool, and then insert the plasma torch nozzle into the inner surface of the cylinder liner, and the cylinder liner is driven by the horizontal idler roller The fixed axis rotates, and the plasma torch nozzle makes a reciprocating linear motion, and scans a spiral hardening zone on the inner surface of the cylinder liner to be processed, which completes the secondary co-infiltration process.

[0058] Wherein, the co-infiltration agent consists of 35 parts by weight of boron carbide powder wi...

Embodiment 3

[0061] Step 1, initial co-infiltration

[0062] After the cylinder liner is preheated at 350°C, it is sent to the salt bath for co-infiltration treatment. The temperature of the salt bath is 520 °C, and the mass concentration of cyanate in the salt bath is 40%. After cleaning, remove the salt and carbon on the surface of the cylinder liner after co-infiltration;

[0063] Step 2, secondary co-infiltration

[0064] Apply a layer of co-penetration agent evenly on the inner surface of the cylinder liner treated in step 1, then place the cylinder liner on the idler roller of the machine tool, and then insert the plasma torch nozzle into the inner surface of the cylinder liner, and the cylinder liner is driven by the horizontal idler roller The fixed axis rotates, and the plasma torch nozzle makes a reciprocating linear motion, and scans a spiral hardening zone on the inner surface of the cylinder liner to be processed, which completes the secondary co-infiltration process.

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com