Transmission connection structure of fan impeller of sweeper truck

A fan impeller and connection structure technology, which is applied in the field of sanitation machinery, can solve the problems of flat key wear, large vibration, and large noise, and achieve the effects of reducing torque and force, prolonging service life, and reducing easy breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

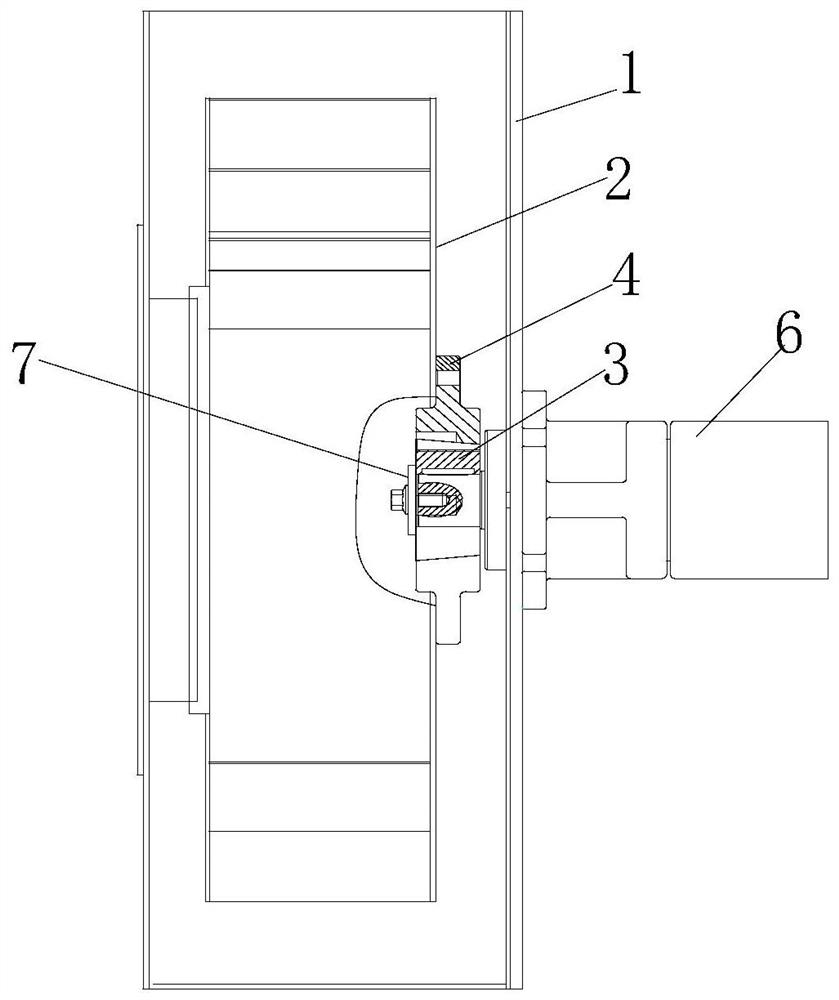

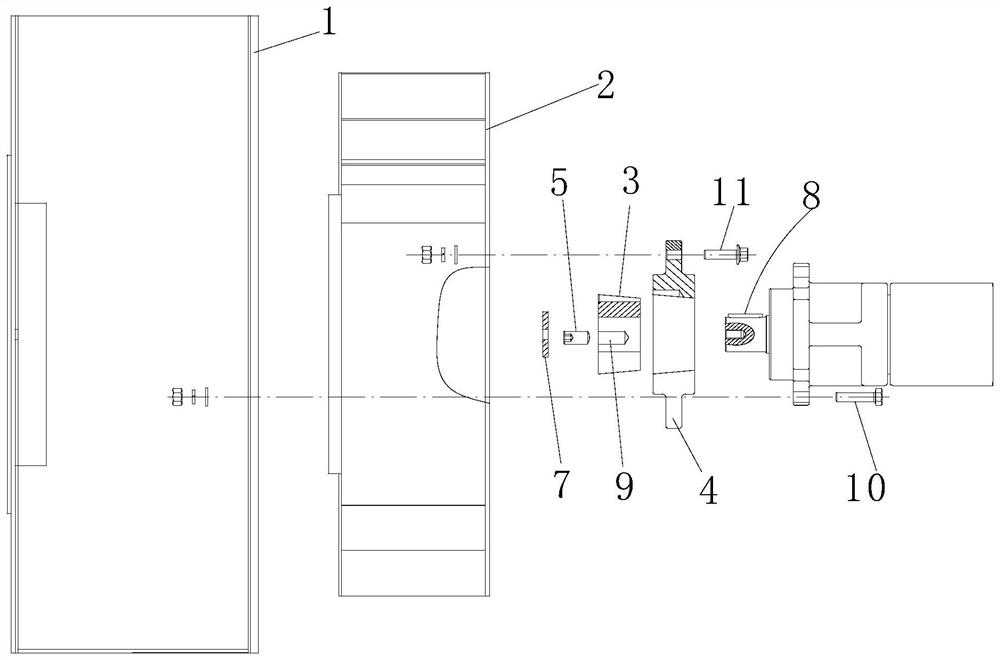

[0022] The transmission connection structure of the fan impeller of the road sweeper of the present embodiment is installed with the fan and the motor as follows: figure 1 and figure 2 As shown, it includes volute 1, impeller 2 inside the volute, tapered bushing 3, impeller flange 4, screw (set screw) 5, motor output shaft 6 and pressure plate 7; volute 1 and motor 6 Fix it with the first fastener 10, fix the impeller flange 4 and the impeller 2 with the second fastener 11, and connect the output shaft (shaft extension) of the motor 6 with the tapered bushing 3 through the flat key 8.

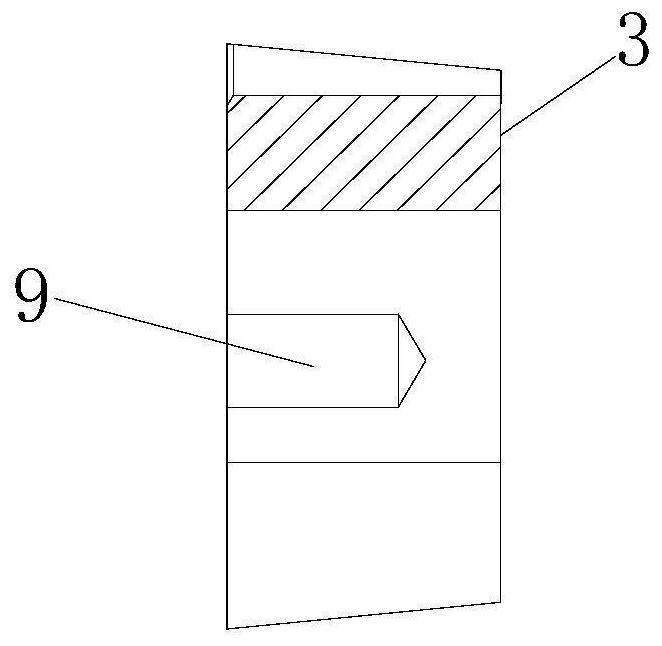

[0023] Such as image 3 As shown, the outer circumference of the tapered bushing 3 forms an outer tapered surface; as Figure 5 As shown, the hollow circumference of the impeller flange 4 forms an inner tapered surface matched with the outer tapered surface of the tapered bushing 3; as figure 1 and figure 2 As shown, the tapered bushing 3 extends into the hollow of the impeller flange fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com