Self-locking type safety clamp capable of being rapidly mounted and detached

A self-locking and safe technology, applied in the direction of friction clamping detachable fasteners, connecting components, mechanical equipment, etc., can solve the safety hazards of installation fixtures, insufficient bolt tightening, easy loss of bolts and other problems. Achieving the effect of avoiding potential safety hazards, convenient assembly and disassembly, and avoiding man-made losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

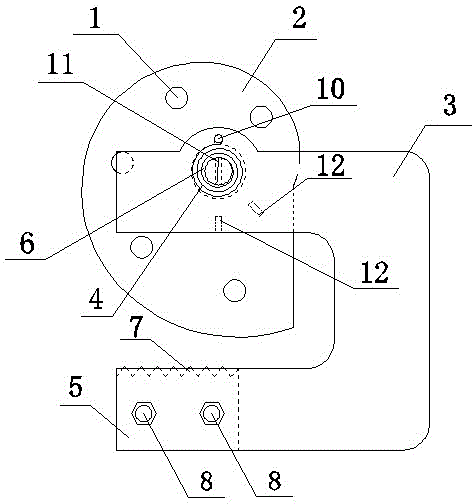

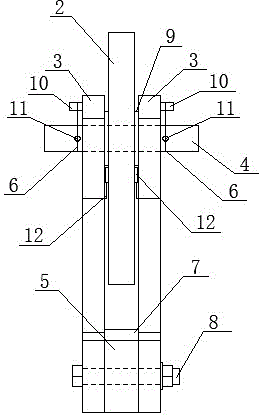

[0032] in accordance with image 3 , The safety net clamp of the present embodiment works on a flange steel plate with a plate thickness of 12mm.

[0033] Installation steps: Rotate the locking part counterclockwise to open, insert the opening of the U-shaped splint against the flange steel plate, then release the locking part, and use the elastic force of the shaft spring itself to fix the clamp on the flange steel plate. After the fixing is complete, select as image 3 As shown in the lanyard hole, the installation is completed by hanging the end of the safety net in the lanyard hole. At this time, the horizontal distance from the tangent point between the outer edge of the locking member and the steel plate to the center of the rotating shaft of the locking member is 7 mm.

Embodiment 2

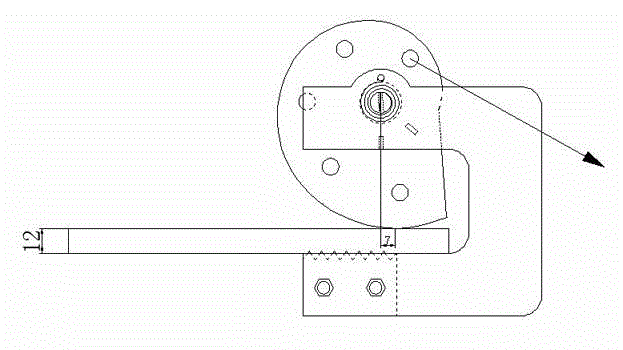

[0035] in accordance with Figure 4 , The safety net clamp of the present embodiment works on a flange steel plate with a plate thickness of 40mm.

[0036] Installation steps: Rotate the locking part counterclockwise to open, insert the opening of the U-shaped splint against the flange steel plate, then release the locking part, and use the elastic force of the shaft spring itself to fix the clamp on the flange steel plate. After the fixing is complete, select as Figure 4 As shown in the lanyard hole, the installation is completed by hanging the end of the safety net in the lanyard hole. At this time, the horizontal distance from the tangent point between the outer edge of the locking member and the steel plate to the center of the rotating shaft of the locking member is 7 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com