Fabricated concrete-filled steel tube pile foundation and construction method thereof

A steel pipe concrete pile and assembly technology, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of poor quality of pouring, temperature stress of expansion and deformation, and large amount of steel used for steel piles, etc., so as to save installation formwork and the steps to remove the formwork, improve the compressive bearing capacity, and facilitate transportation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

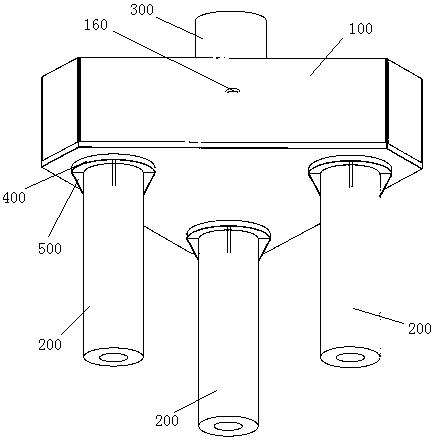

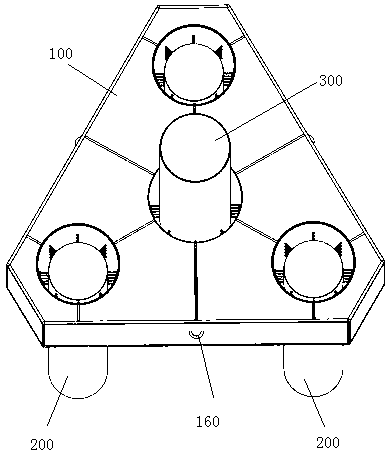

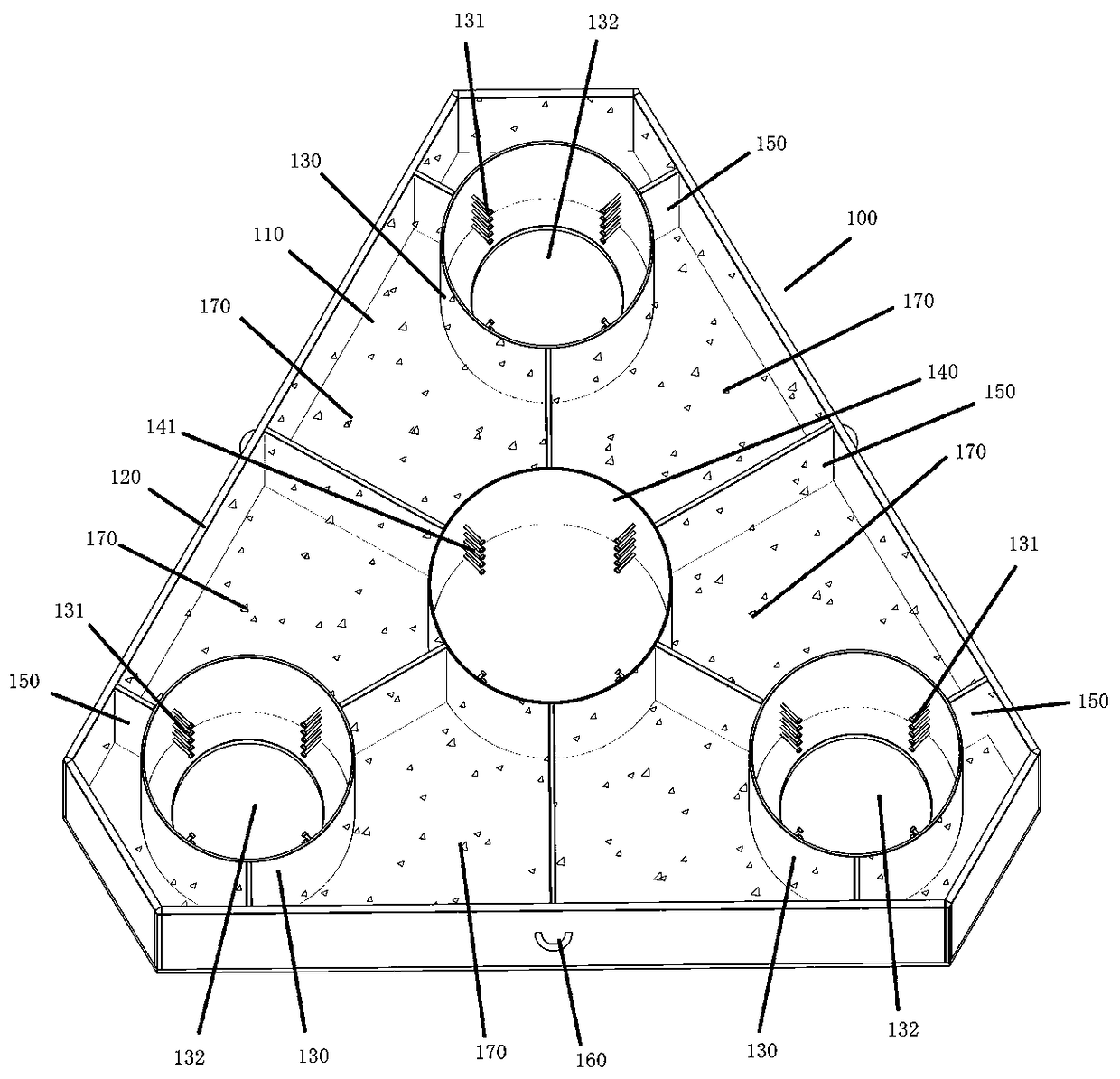

[0030] Such as Figure 1~8 As shown, a prefabricated steel pipe concrete pile foundation includes a cap 100 , a support pile 200 for supporting the cap 100 is arranged under the cap 100 , and a support column 300 extending upward is arranged at the upper end of the cap 100 . The support pile 200, the cap 100, and the support column 300 are arranged in a modular manner, which is convenient for overall fabrication and installation.

[0031] In this embodiment, an annular corbel 400 is provided between the supporting pile 200 and the cap 100 , a stiffening rib 500 is provided below the annular corbel 400 , and a shear peg A210 is provided at the upper end of the supporting pile 200 . The ring-shaped corbel 400 can support the cap 100 , and the stiffener 500 can prevent the corbel 400 from being unstable and enhance the bearing capacity of the corbel 400 .

[0032] In this embodiment, the platform 100 includes a bottom plate 110, on the outer periphery of the bottom plate 110, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com