Method for construction of cast-in-place concrete anchor pile

A technology of concrete anchor and construction method, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of device assembly and construction trouble of pull-out force, and achieve simple construction method, high compressive bearing capacity, easy The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

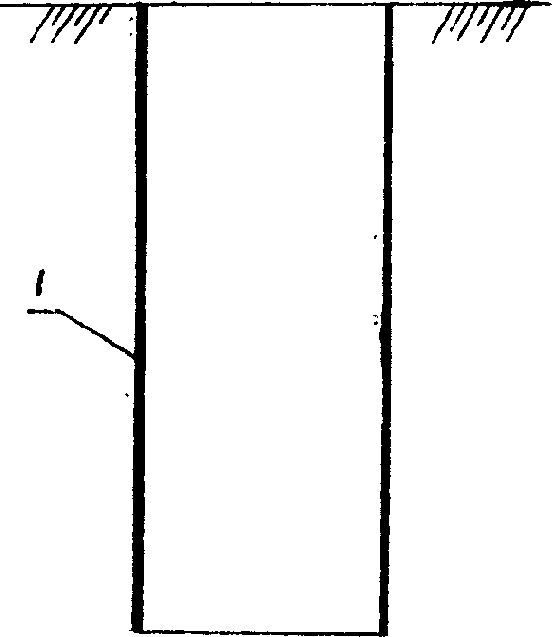

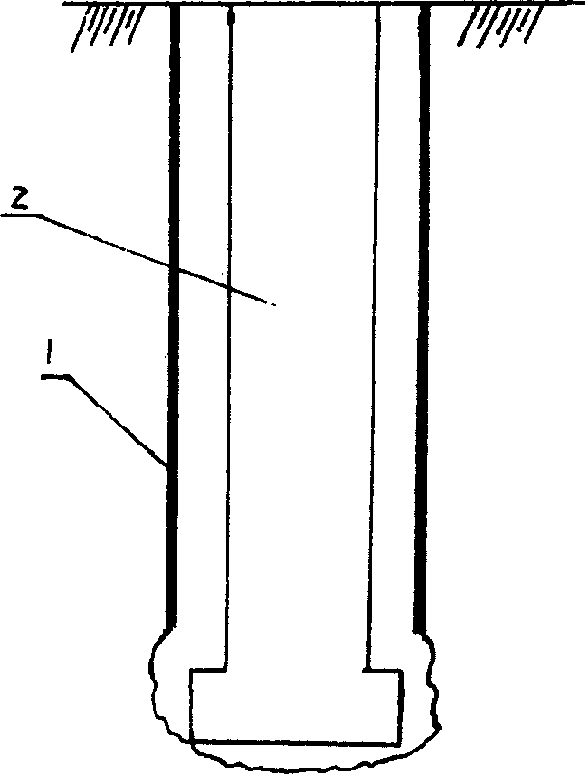

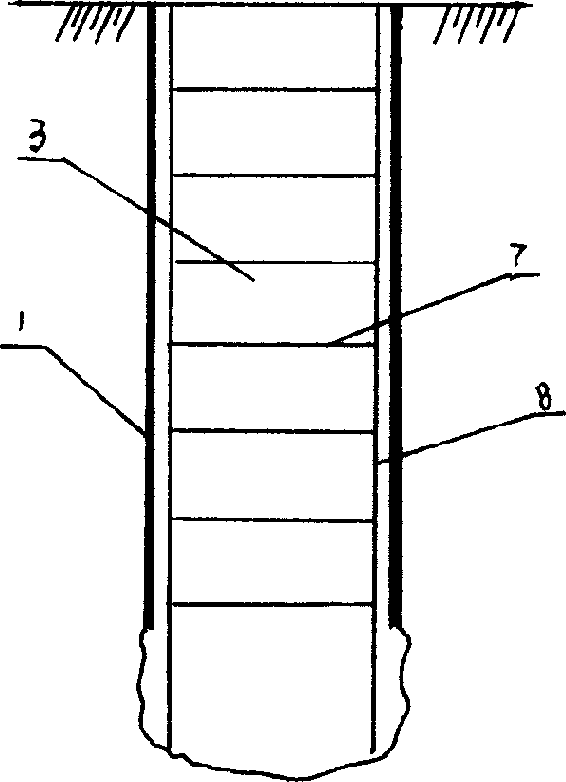

[0019] The construction method of cast-in-situ concrete anchor pile of the present invention is carried out like this, at first, as Figure 1a As shown, drive the outer casing 1 into the foundation until the specified depth, and then Figure 1b As shown, with the outer casing 1 as a guide, the heavy hammer 2 repeatedly rams the foundation soil at the bottom of the outer casing 1 up and down until the above-mentioned heavy hammer 2 extends downward for a specified distance from the bottom of the outer casing 1 and forms a pile end holes, then as in Figure 1c As shown, the above-mentioned weight 2 is lifted upwards from the top of the above-mentioned outer casing 1, and then a reinforcement cage 3 is inserted into the above-mentioned casing 1. The bottom of the reinforcement cage 3 is formed with an expandable diameter portion 6, and the diameter-expandable portion 6 It is mainly formed by longitudinal steel bars, and the part (upper part) in the steel cage 3 other than the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com