Self-positioning internally-installed steel bar U-shaped composite beam

A composite beam, self-positioning technology, applied in the direction of structural elements, building components, long-strip structural components for load-bearing, etc. Cost requirements, do not reflect the huge advantages of steel-concrete structures, etc., achieve significant social and economic benefits, high concrete compressive bearing capacity, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

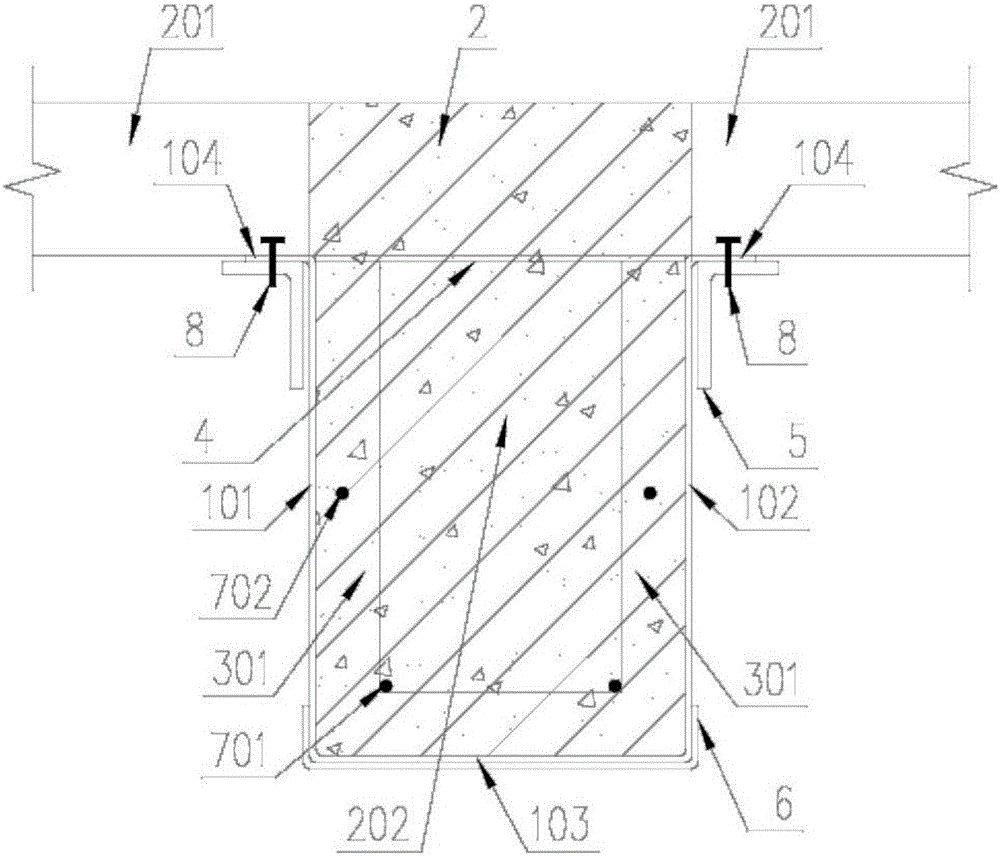

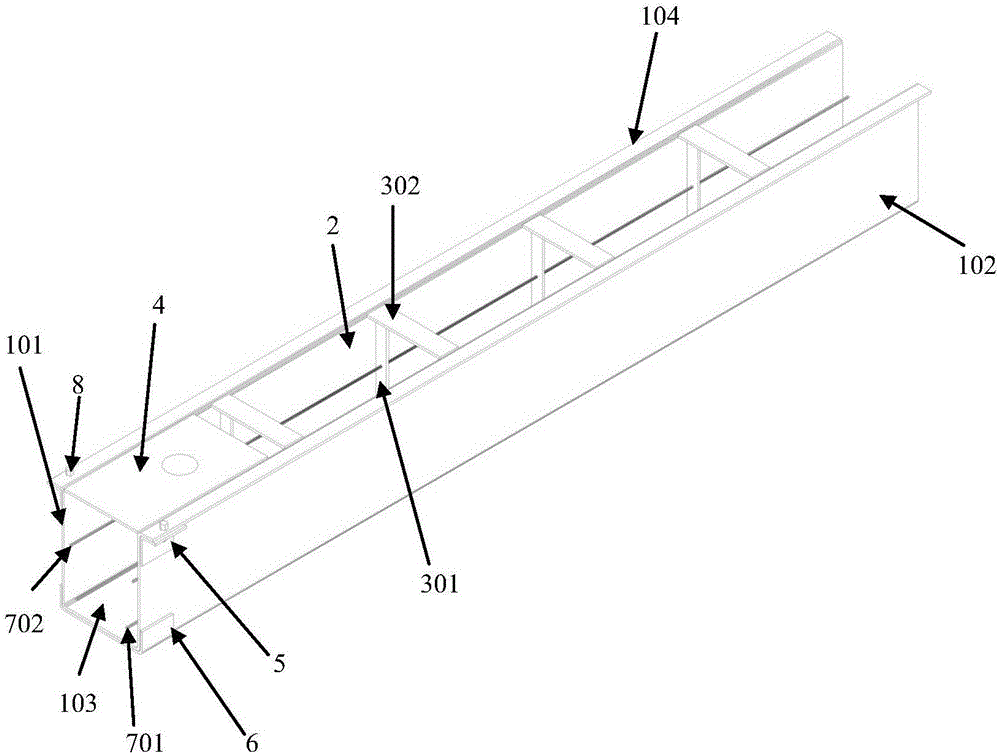

[0020] see figure 1 , the object of the present invention is to provide a self-positioning U-shaped composite beam with built-in reinforcement to overcome the defects in the prior art.

[0021] The U-shaped composite beam includes a U-shaped steel beam shell 1, a concrete girder 2, a reinforcement plate 3 and an upper cover plate 4, angle steel 5, channel steel 6, steel bars 7, and positioning pins 8;

[0022] The U-shaped steel beam shell 1 according to the claims, comprising a left side plate 101, a right side plate 102, a bottom plate 103 and a flange plate 104;

[0023] The bottom of the left side plate 101 and the bottom of the right side plate 102 are respectively connected with the two sides of the bottom plate 103, and are connected into one body, and the end of the flange plate 104 is connected with the left side plate 101 It is integrated with the top of the right side plate 102 and is perpendicular to the left side plate 101 and the right side plate 102;

[0024] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com