Steel-wood combined column and combination method

A technology of steel-wood combination and combination method, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of weak links formed by wood components, affecting the ability of combination to deform under force, and uneven rigidity, so as to achieve the improvement and stress Performance, improve the compressive bearing capacity, improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

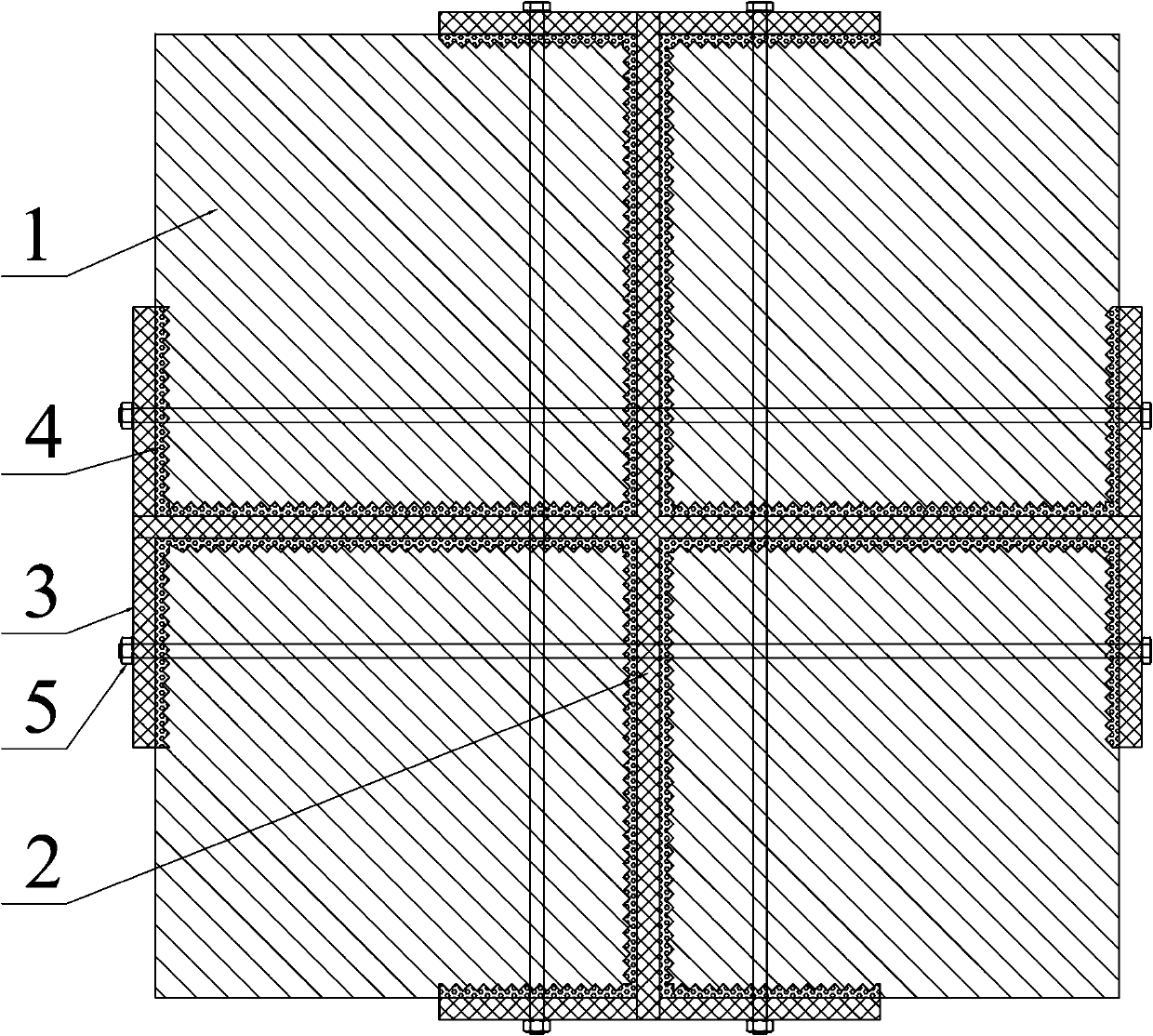

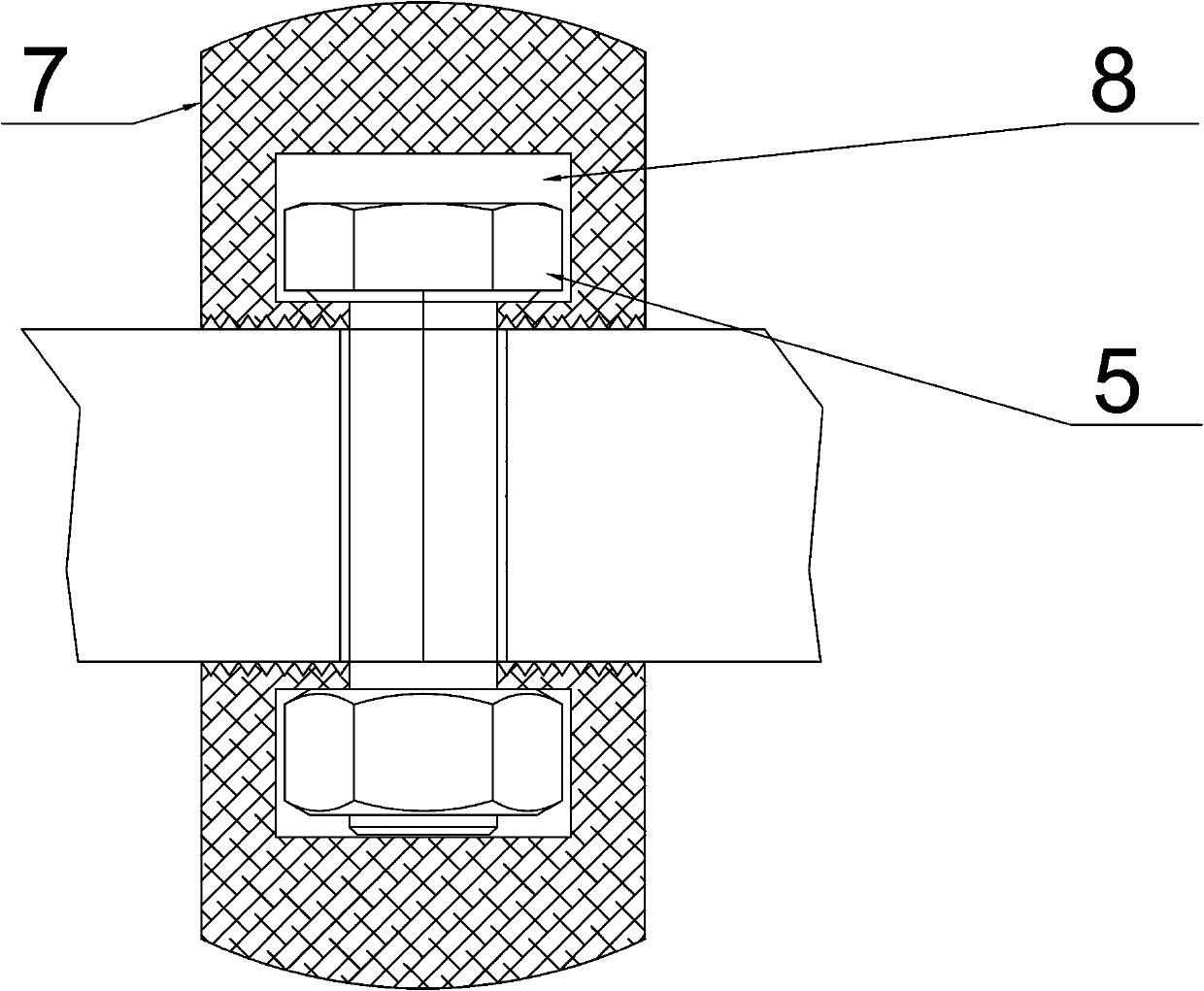

[0028] like figure 1 As shown, a steel-wood composite column includes section steel and glued wood 1, glued wood 1 is cross-glued wood, section steel includes cross-shaped steel 2 and short straight-shaped steel 3, cross-shaped steel 2 has four ends, and each end The two sides of the head are respectively welded with short straight steel 3, and the two sides of each end of the cross steel 2 are welded with short straight steel 3 to form a T shape, and the space between the cross steel 2 and the short straight steel 3 is sandwiched with glulam 1. The glulam 1, the cross-shaped steel 2 and the short-shaped steel 3 are all provided with preset holes corresponding to the positions, and multiple sets of bolts 5 pass through the short-shaped steel 3 on opposite sides around them, and the glulam 1 and the glulam 1 between them. The cross-shaped steel 2 locks and connects the whole into one body; the rubber pad 4 is sandwiched between the steel and the glued wood 1, and the side of th...

Embodiment 2

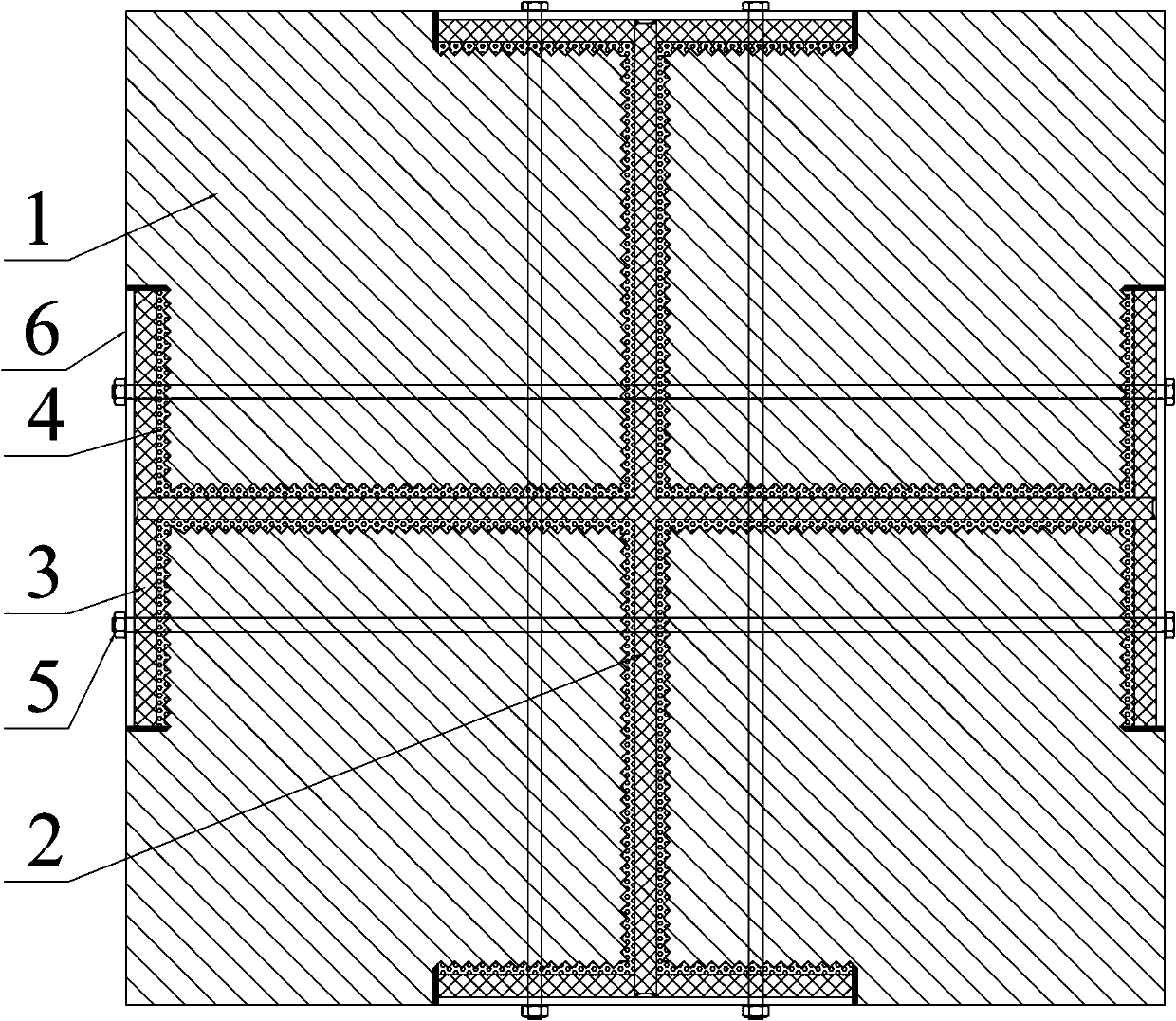

[0030] like figure 2 As shown, a steel-wood composite column includes section steel and glued wood 1, glued wood 1 is cross-glued wood, section steel includes cross-shaped steel 2 and short straight-shaped steel 3, cross-shaped steel 2 has four ends, and each end The two sides of the head are respectively welded with short straight steel 3, and the two sides of each end of the cross steel 2 are welded with short straight steel 3 to form a T shape, and the space between the cross steel 2 and the short straight steel 3 is sandwiched with glulam 1. The glulam 1, the cross-shaped steel 2 and the short-shaped steel 3 are all provided with preset holes corresponding to the positions, and multiple sets of bolts 5 pass through the short-shaped steel 3 on opposite sides around them, and the glulam 1 and the glulam 1 between them. The cross-shaped steel 2 locks and connects the whole into one body; the rubber pad 4 is sandwiched between the steel and the glued wood 1, and the side of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com