Locking system for floorboards

a locking system and floor board technology, applied in the direction of roof coverings, structural elements, building components, etc., can solve the problems of significantly more difficult taking up and function, and achieve the effect of facilitating the opening of the locking when taking up an installed floor, not easily visible, and easy angled downwards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

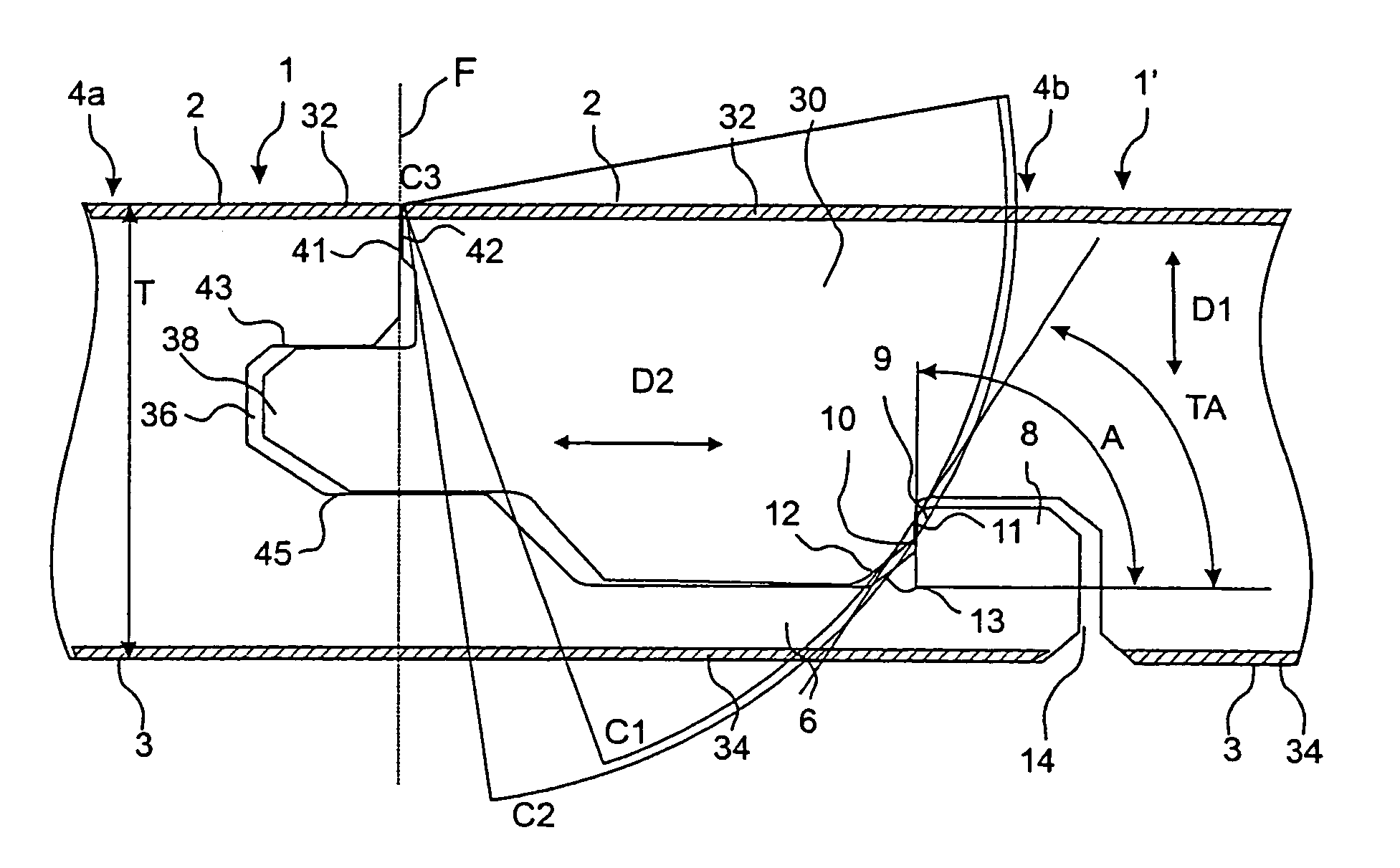

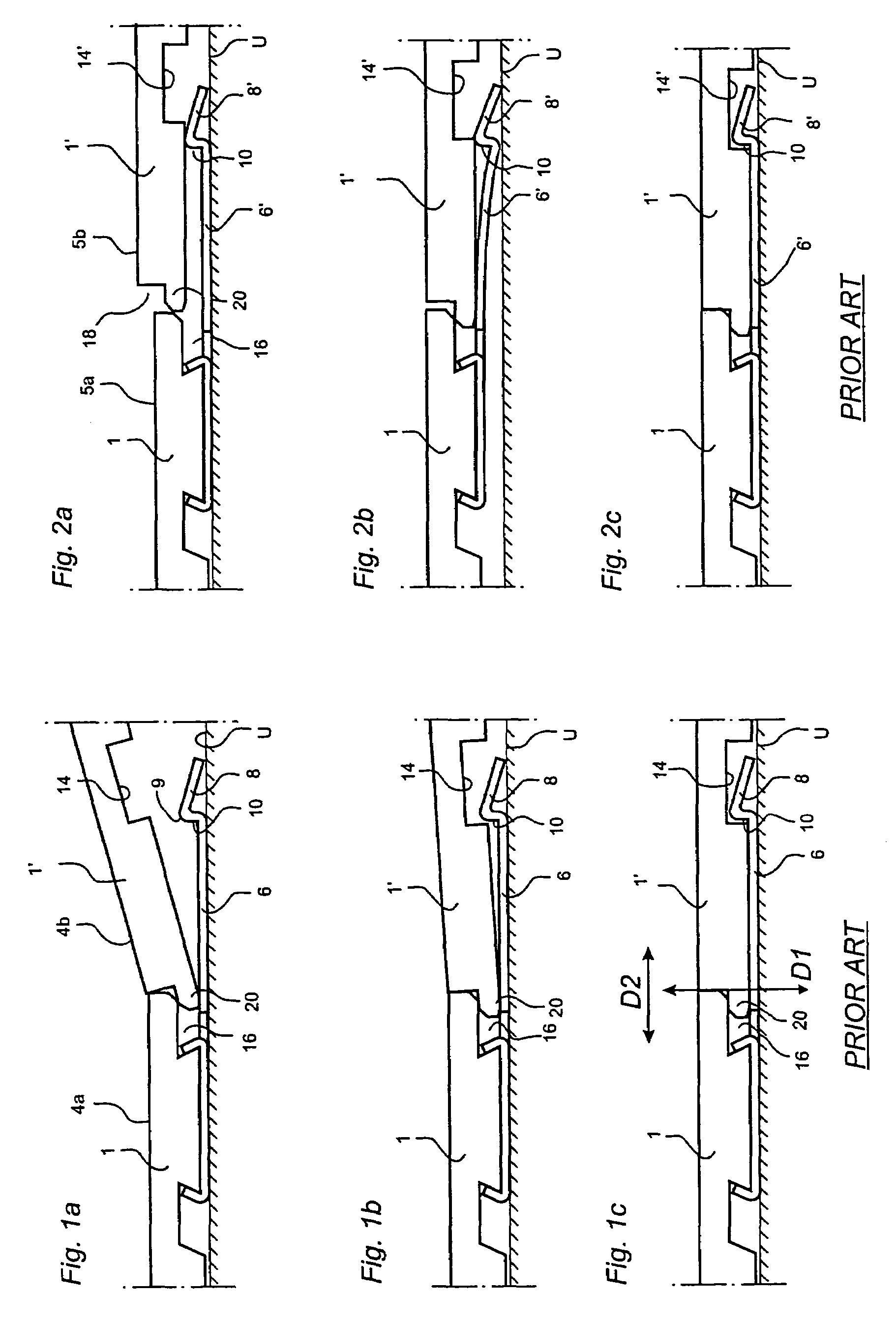

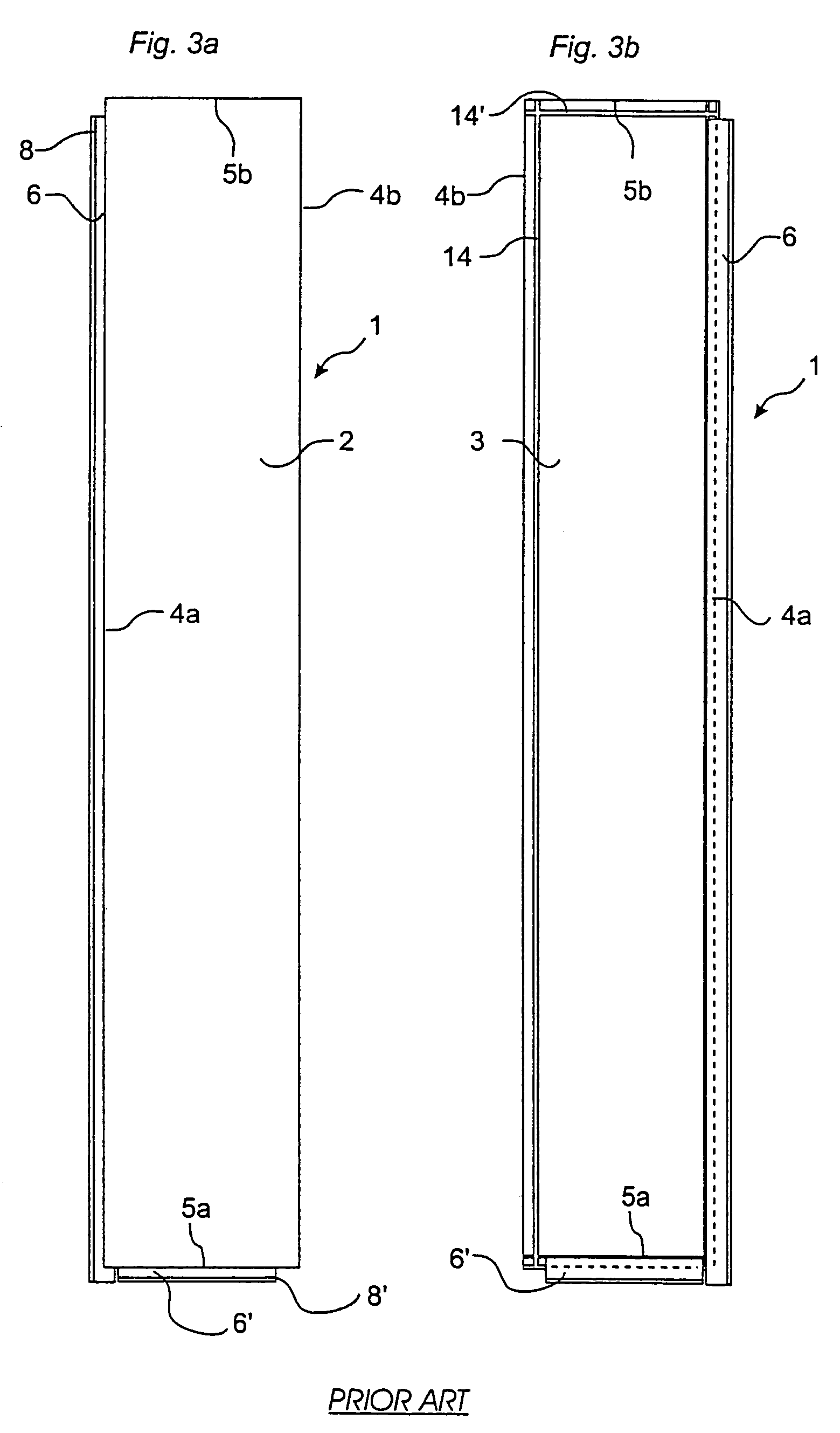

[0051]Prior to the description of preferred embodiments, with reference to FIG. 5, a detailed explanation will first be given of the most important parts in a strip lock system.

[0052]The invention can be applied in joint systems with a worked strip which is made in one piece with the core of the board, or with a strip which is integrated with the core of the board but which has been made of a separate material, for instance aluminium. Since the worked embodiment, where strip and core are made of the same material, constitutes the greatest problem owing to higher friction and poorer flexibility, the following description will focus on this field of application.

[0053]The cross-sections shown in FIG. 5 are hypothetical, not published cross-sections, but they are fairly similar to the locking system of the known floorboard “Fiboloc®” and to the locking system according to WO 9966151. Accordingly, FIG. 5 does not represent the invention but is only used a starting point of a description ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com