Method realizing drainage and consolidation of hydraulic fill soil as well as soil mass improvement through utilizing straw pile

A technology of drainage and consolidation, blowing and filling, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of pollution cost and long period of blowing and filling methods, and achieves good effect, high social benefit and economy. The effect of high efficiency and greening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

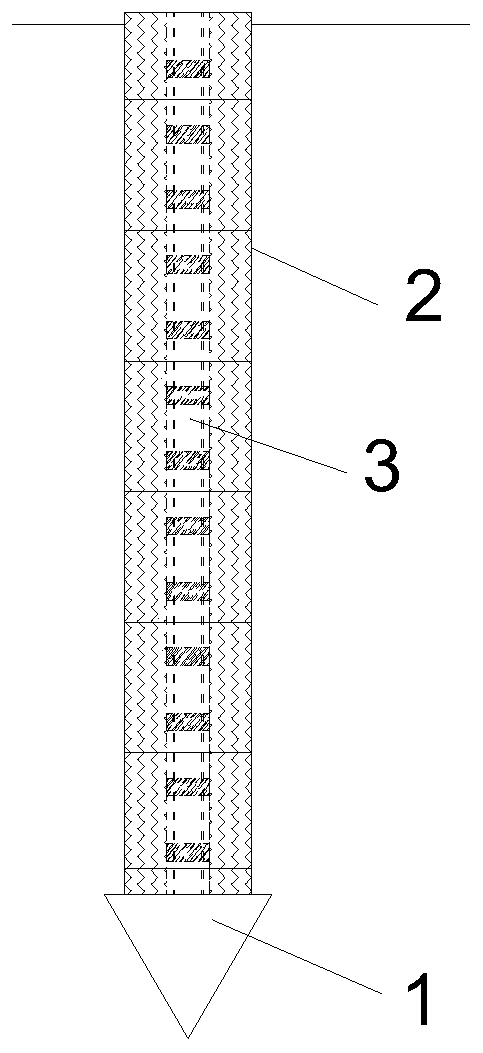

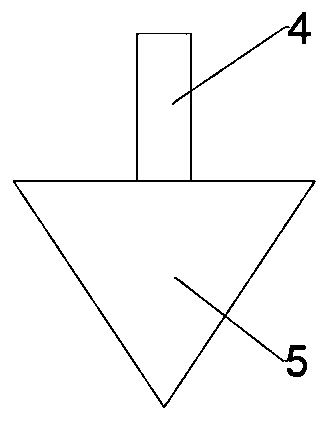

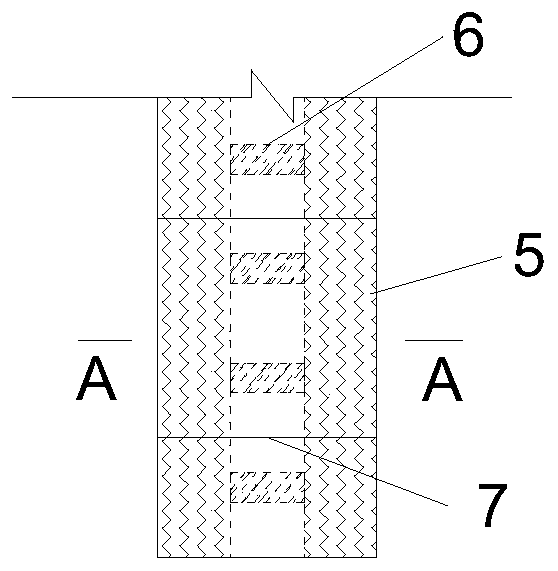

[0040] refer to Figure 1 to Figure 4 , a straw pile for drainage consolidation and improvement of dredged fill soil, comprising a pile head 1, a straw pile body 2 and a compression pile core 3; the upper end of the pile head 1 is provided with a connecting rod 4, and the pile head 1 and the straw The pile body 2 is connected by a connecting rod 4; the inside of the straw pile body 2 is uniformly provided with a lining ring 6 from top to bottom; the compression pile core 3 is inserted into the inside of the lining ring 6.

[0041] Specifically, refer to figure 1 , the pile head 1 is in an inverted conical shape, and the diameter of the top of the pile head 1 is larger than that of the straw pile body 2, which can delay the contact between the dredged fill soil and the straw pile body 2 when pressing in, reduce resistance, and facilitate the pressing of the straw pile enter.

[0042] Specifically, the material of the pile head 1 is a material with slow-release and foaming fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com