Concrete filled steel tube core column reinforced prefabricated assembly type shear wall unit

A technology of concrete filled steel tube and prefabricated assembly, which is applied to walls, building components, buildings, etc., can solve the problems of low production efficiency and high cost of steel reinforcement for shear walls, so as to improve the compressive bearing capacity and reduce labor operations. Strength, the effect of improving the speed of construction work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment

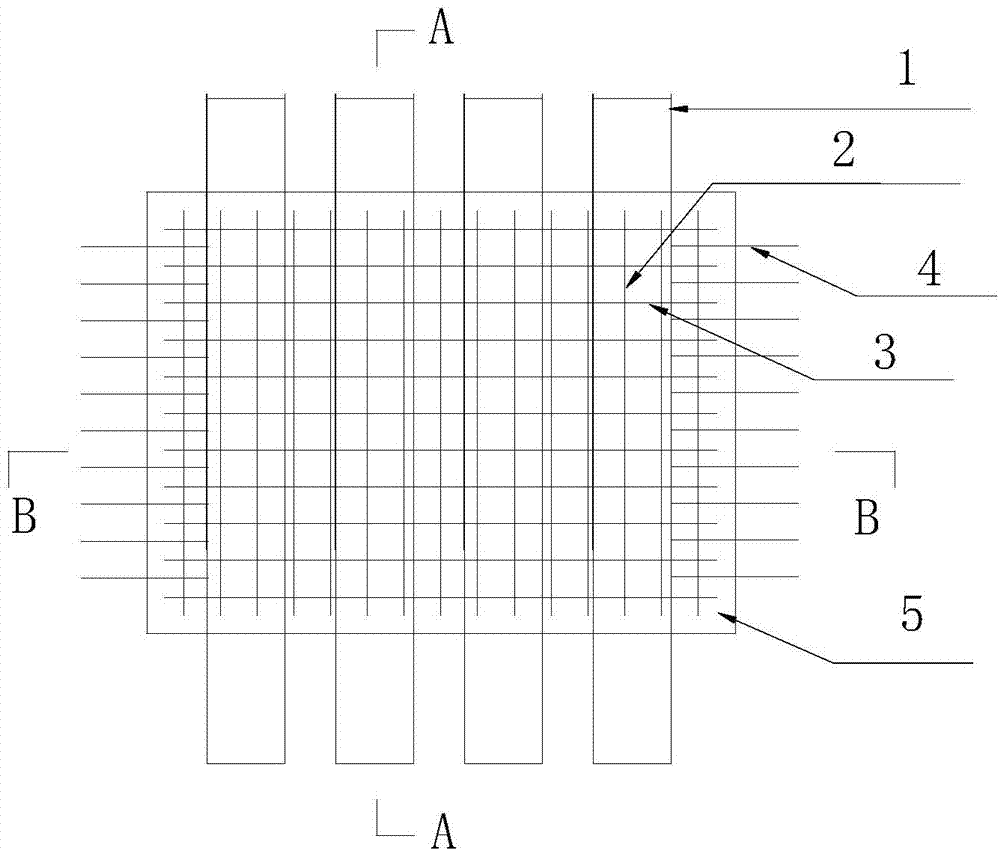

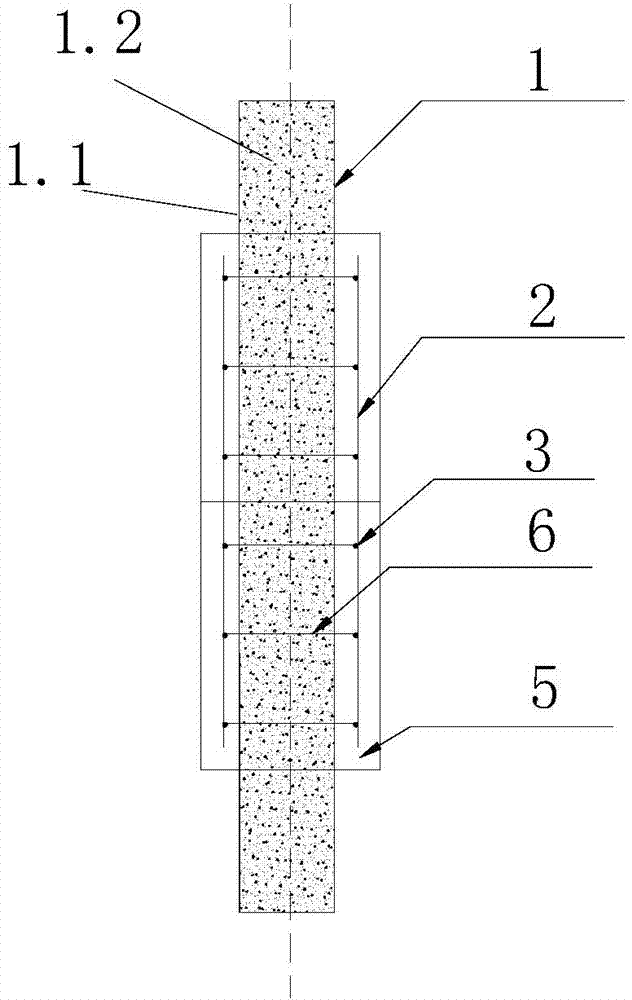

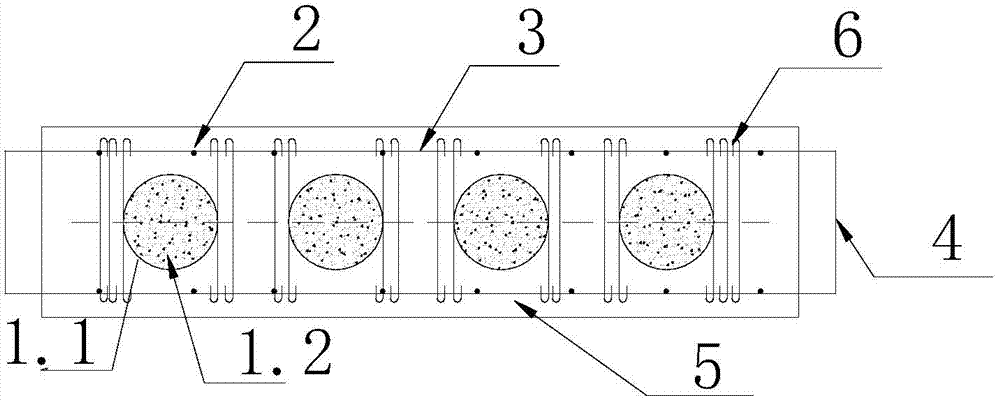

[0016] like figure 1 As shown, the reinforced prefabricated prefabricated shear wall unit of steel tube concrete core column includes uniformly distributed circular steel tube concrete core column 1, multiple vertical steel bars 2 evenly distributed vertically, transverse steel bars 3 connected between vertical steel bars, prefabricated Leave connecting bars 4, outsourcing concrete 5 and tie bars 6. The circular concrete-filled steel tube core columns 1 are vertically and uniformly arranged at equal intervals and fixed between the double-layer vertically distributed steel bars 2 and the horizontal steel bars 3. The spacing between the two layers of mesh does not change. like image 3 As shown, the circular steel pipe concrete core column 1 is composed of a circular steel pipe 1.1 and a concrete column core 1.2 poured and filled in the cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com