Preparation of non-magnetic high corrosion resistant amorphous steel coating

A high-corrosion, amorphous steel technology, applied in coating, metal material coating process, heating inorganic powder coating, etc., can solve the problems of high brittleness and limitation, achieve low porosity, good magnetic properties, optimized Effects of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

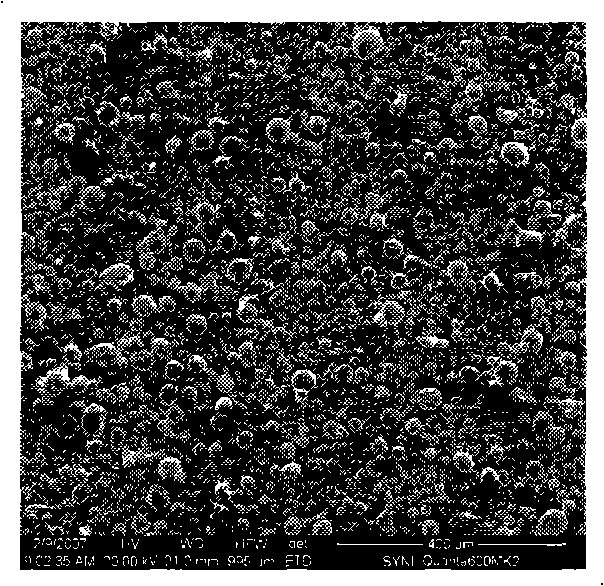

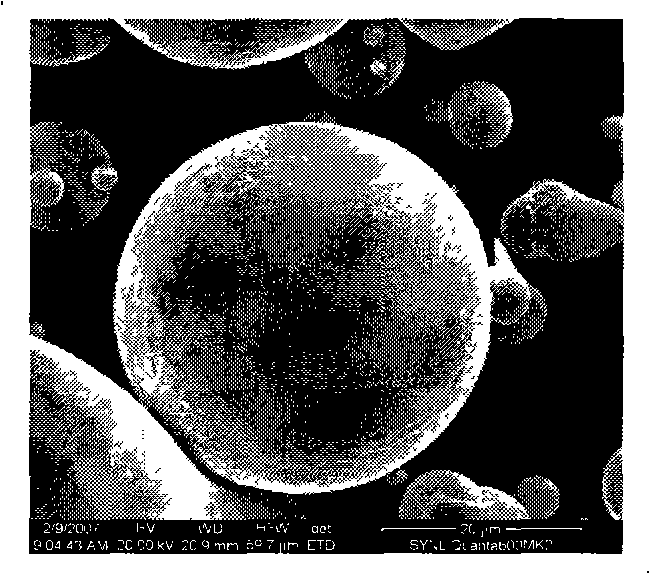

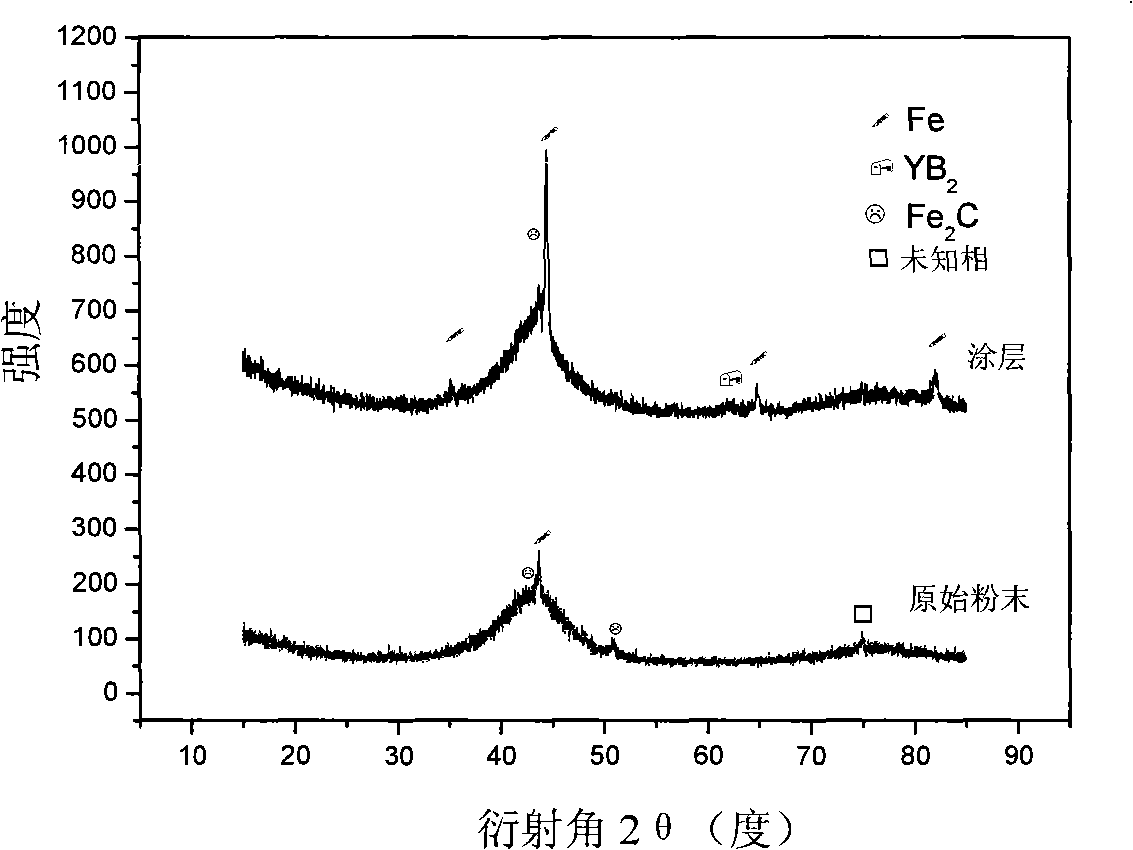

[0032] (1) First, the master alloy is prepared by vacuum induction melting according to the required composition, and the nominal composition of the alloy is Fe 48 Cr 15 Mo 14 C 15 B 6 Y 2 , the amorphous alloy powder was prepared by gas atomization method, and the specific process parameters of gas atomization in this embodiment were atomization pressure 5 MPa and atomization temperature 1200°C. See Figure 1(a)-(b). The powder is spherical in shape, has good fluidity and filling ability, and is suitable as a precursor powder for thermal spraying.

[0033] (2) Then choose amorphous powder with a particle size of 16-45μm, and use supersonic flame spraying technology (HVOF). The specific process parameters are that the pressure of kerosene and oxygen are 160psi and 180psi respectively, the powder feeding speed is 65g / min, and the distance is 350mm. Gun barrel length 4-6 inch, is coated on the substrate (submarine flat bulb steel 921A), prepares amorphous coating (see figu...

Embodiment 2

[0054] The difference from Example 1 is:

[0055] The specific process parameters of supersonic flame spraying in this embodiment are spraying distance 350mm, powder feeding speed 25g / min;

[0056] Results: A non-magnetic high corrosion and wear-resistant amorphous steel coating was obtained. The coating thickness was 400 μm, the volume content of amorphous phase was about 74%, and the coating hardness was 573Hv, but the corrosion performance did not change significantly.

Embodiment 3

[0058] The difference from Example 1 is:

[0059] The supersonic flame spraying specific process parameters of the present embodiment are spraying distance 250mm, powder feeding speed 60g / min;

[0060] Results: A non-magnetic, highly corrosion-resistant and wear-resistant amorphous steel coating was obtained. The coating thickness was 600 μm, the volume content of amorphous phase was about 83%, and the coating hardness was 740Hv, but the corrosion performance did not change significantly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com