Electrohydraulic control system of anti-explosion hydraulic winch

An electro-hydraulic control system and hydraulic winch technology, applied in the mechanical field, can solve problems such as pressure shock, poor stability, and low automation level, and achieve the effects of reduced troubleshooting time, good speed following characteristics, and improved automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the drawings and embodiments.

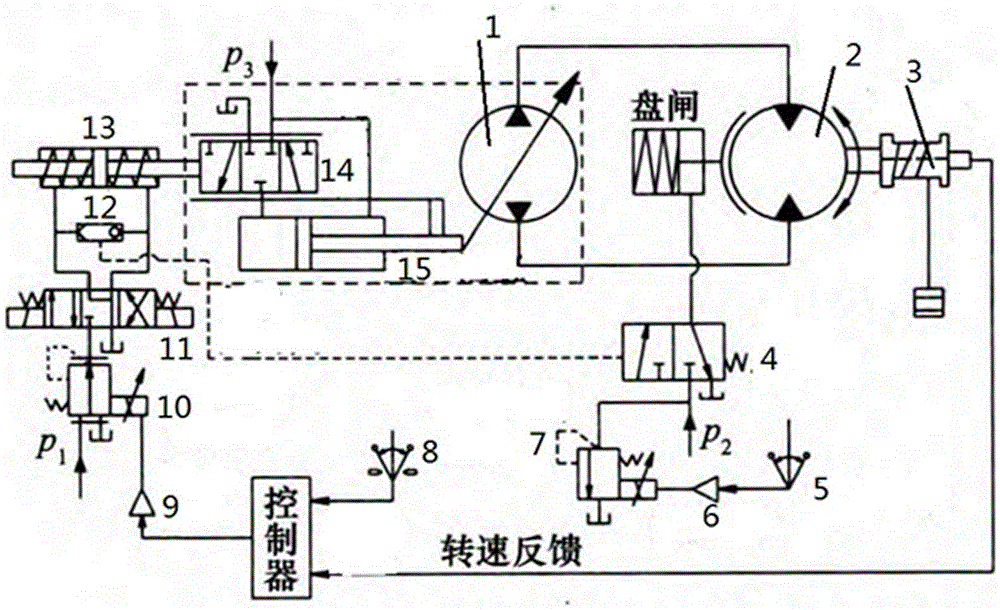

[0014] Such as figure 1 , The electro-hydraulic proportional control system adopts dual-handle control, the drive handle controls the rotation of the drive motor, and the brake handle controls the motor braking. Therefore, the brake handle can be used to adjust the braking force and braking time, which can realize the coordinated control of driving and braking. . The drive system and brake system are the core of the electro-hydraulic proportional control system of the explosion-proof hydraulic winch, including the electro-hydraulic proportional drive system and the electro-hydraulic proportional brake system.

[0015] The electro-hydraulic proportional drive system is formed by adding a drive handle, electro-hydraulic proportional pressure reducing valve, electromagnetic reversing valve, rotary encoder, amplifier 1 and controller on the basis of the original drive circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com