Pitch and stickies control in pulp and papermaking processes

A pulping and anti-sticking agent technology, applied in textiles and papermaking, fat/resin/pitch/wax removal of pulp, papermaking, etc., can solve problems such as paper quality deterioration and productivity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

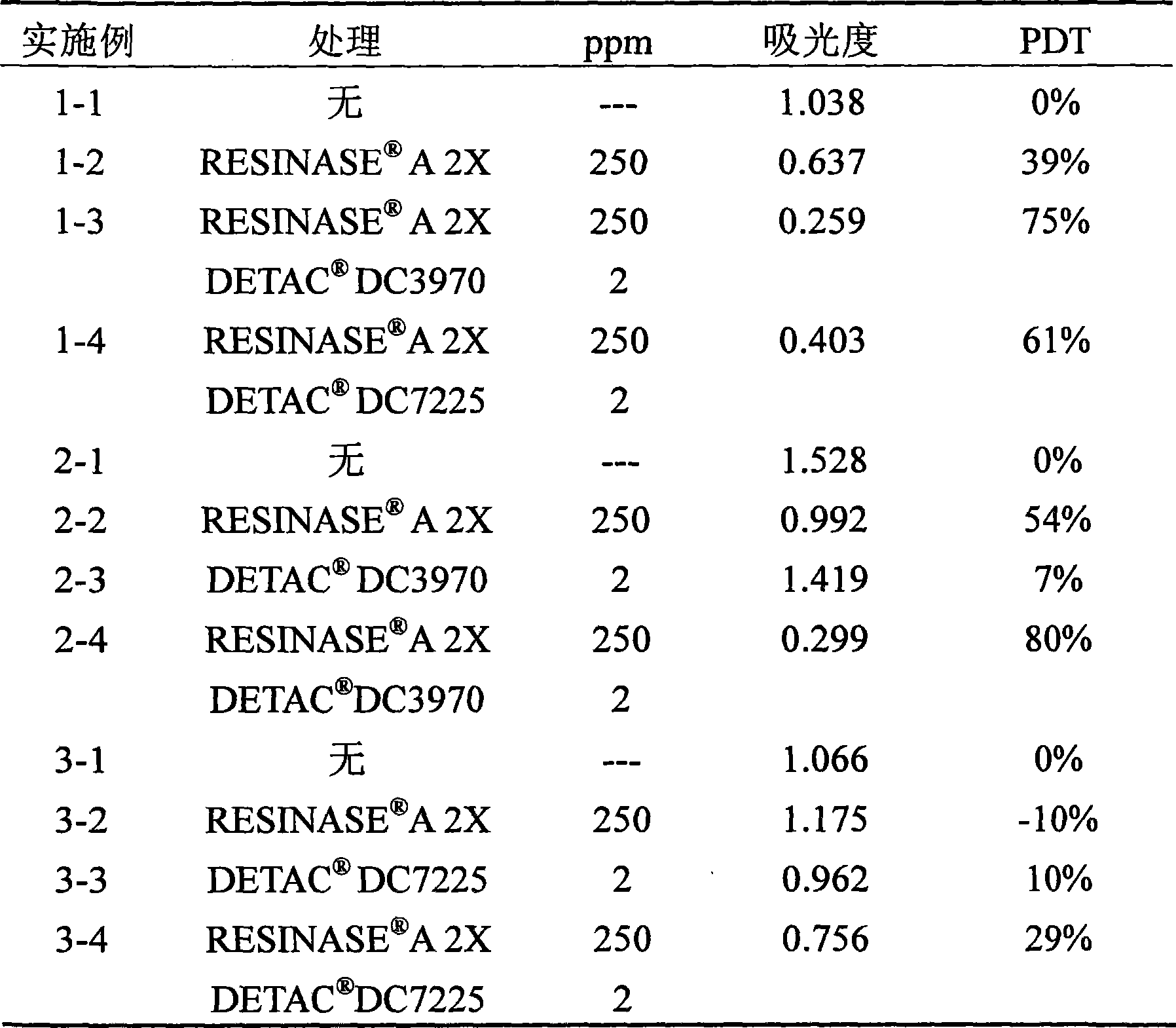

[0036] Pitch Deposition Test (PDT)

[0037] The Pitch Deposition Test (PDT) was performed to determine the efficacy of the compositions of the present invention as deposition control agents. In this test, 6 ml of a 25% by weight solution of calcium chloride dihydrate was added to bleached hardwood kraft pulp of 0.5% consistency diluted with DI (deionized) water at a temperature of about 50°C, and 140 ml of a solution preheated to about Synthetic pitch at 50°C. The synthetic resin was prepared according to the following method: 4.0 grams of Wesson brand corn oil (ConAgra Foods, Inc., Omaha, NE, USA) and 1.0 grams of Sylvatol 40 (Arizona Chemical, Jacksonville, FL, USA) were mixed together, This was then charged into 995.0 grams of DI water, warmed to about 50°C, and mixed for 2 minutes with a Silverson L4RT laboratory mixer fitted with an emulsifier screen. After addition of the synthetic resin, an aliquot of the test solution is transferred to a suitable beaker and mixed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com