Water-based matt handfeel oil and preparation method thereof

An oily, water-based technology that can be used in biocide-containing paints, antifouling/underwater coatings, coatings, etc., and can solve the problem of poor touch feeling of varnish coating, powder drop, and overall effect of gift packaging. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

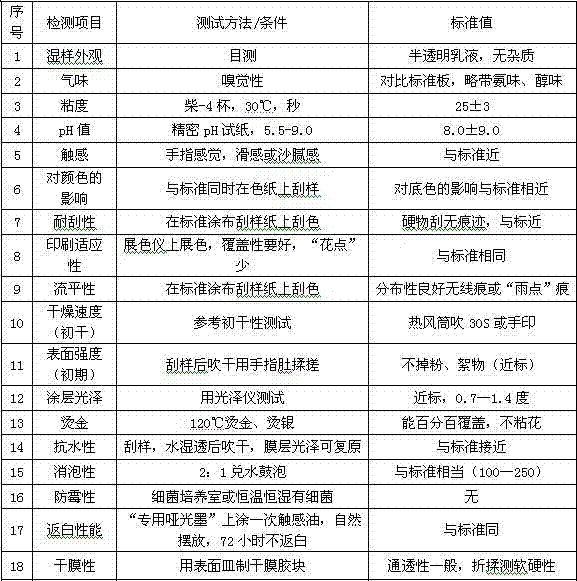

Image

Examples

Embodiment 1

[0078] A water-based matte feel oil, which is composed of the following raw materials in parts by weight: 70 parts of matte polyurethane resin, 5 parts of bright polyurethane resin, 1 part of alcohol, 1 part of water, 1 part of polyester polyol, 0.5 part of high molecular weight polyol Dimethicone emulsion, 1 part leveling agent, 1 part antiwear agent, 0.1 part antifungal agent, 0.1 part defoamer, 0.1 part polyurethane thickener, 0.4 part aziridine crosslinking agent.

[0079] The preparation method of the water-based matte feel oil of the present embodiment comprises the following preparation steps: a. 70 parts of matte polyurethane resin, 5 parts of bright polyurethane resin, 1 part of alcohol, 1 part of water, 1 part of polyester polyol, 0.5 1 part of high molecular weight polydimethylsiloxane emulsion, 1 part of leveling agent, 1 part of antiwear agent, 0.1 part of antifungal agent, 0.1 part of defoamer, 0.1 part of polyurethane thickener and stir evenly for 15 minutes; b....

Embodiment 2

[0081] A water-based matte feel oil, which is composed of the following raw materials in parts by weight: 90 parts of matte polyurethane resin, 15 parts of bright polyurethane resin, 5 parts of alcohol, 5 parts of water, 5 parts of polyester polyol, 1.5 parts of high molecular weight polyol Dimethicone emulsion, 4 parts of leveling agent, 10 parts of antiwear agent, 0.6 part of antifungal agent, 0.6 part of defoamer, 1 part of polyurethane thickener, 1.5 parts of aziridine crosslinking agent.

[0082] The preparation method of the water-based matte feel oil of the present embodiment comprises the following preparation steps: a. 90 parts of matte polyurethane resin, 15 parts of bright polyurethane resin, 5 parts of alcohol, 5 parts of water, 5 parts of polyester polyol, 1.5 parts 1 part of high molecular weight polydimethylsiloxane emulsion, 4 parts of leveling agent, 10 parts of antiwear agent, 0.6 part of antifungal agent, 0.6 part of defoamer, and 1 part of polyurethane thick...

Embodiment 3

[0084] A water-based matte feel oil, which is composed of the following raw materials in parts by weight: 72 parts of matte polyurethane resin, 7 parts of bright polyurethane resin, 2 parts of alcohol, 1 part of water, 1 part of polyester polyol, 0.5 part of high molecular weight polyol Dimethicone emulsion, 2 parts of leveling agent, 2 parts of antiwear agent, 0.1 part of antifungal agent, 0.2 part of defoamer, 0.2 part of polyurethane thickener, 0.5 part of aziridine crosslinking agent.

[0085] The preparation method of the water-based matte feel oil of the present embodiment comprises the following preparation steps: a. 72 parts of matte polyurethane resin, 7 parts of bright polyurethane resin, 2 parts of alcohol, 1 part of water, 1 part of polyester polyol, 0.5 1 part of high molecular weight polydimethylsiloxane emulsion, 2 parts of leveling agent, 2 parts of anti-wear agent, 0.1 part of anti-fungal agent, 0.2 part of defoamer, 0.2 part of polyurethane thickener and stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com