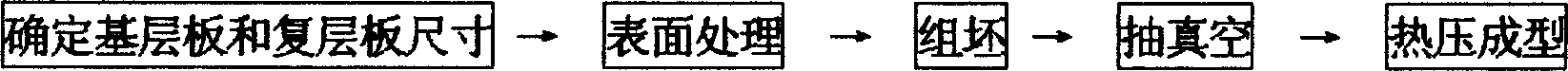

Processing method of press forming soldering high rolling composite blank

A technology of hot-rolling compounding and processing methods, which is applied in the direction of manufacturing tools, metal processing equipment, welding media, etc., can solve the problems of large consumption of welding materials and labor, scarcity of resources, and large loss of trimming, and achieve huge economic benefits and Social benefits, reduced welding workload, and reduced trimming loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Manufacture composite blanks of carbon steel and stainless steel with width and length 2000mm×350mm×thickness 150mm, of which the thickness of stainless steel is 12mm and that of ordinary carbon steel is 63mm. Here, the length and width of the base metal plate are the length and width of the composite billet. First, select two base Q235 carbon steel plates with a size of 2000mm×350mm×63mm. According to the size of the base metal plate, subtract the extension gap in the length direction of 10mm×2 , The extension gap in the width direction is 5mm×2, and the size of the two clad 304 stainless steel plates is 1980mm×340mm×12mm.

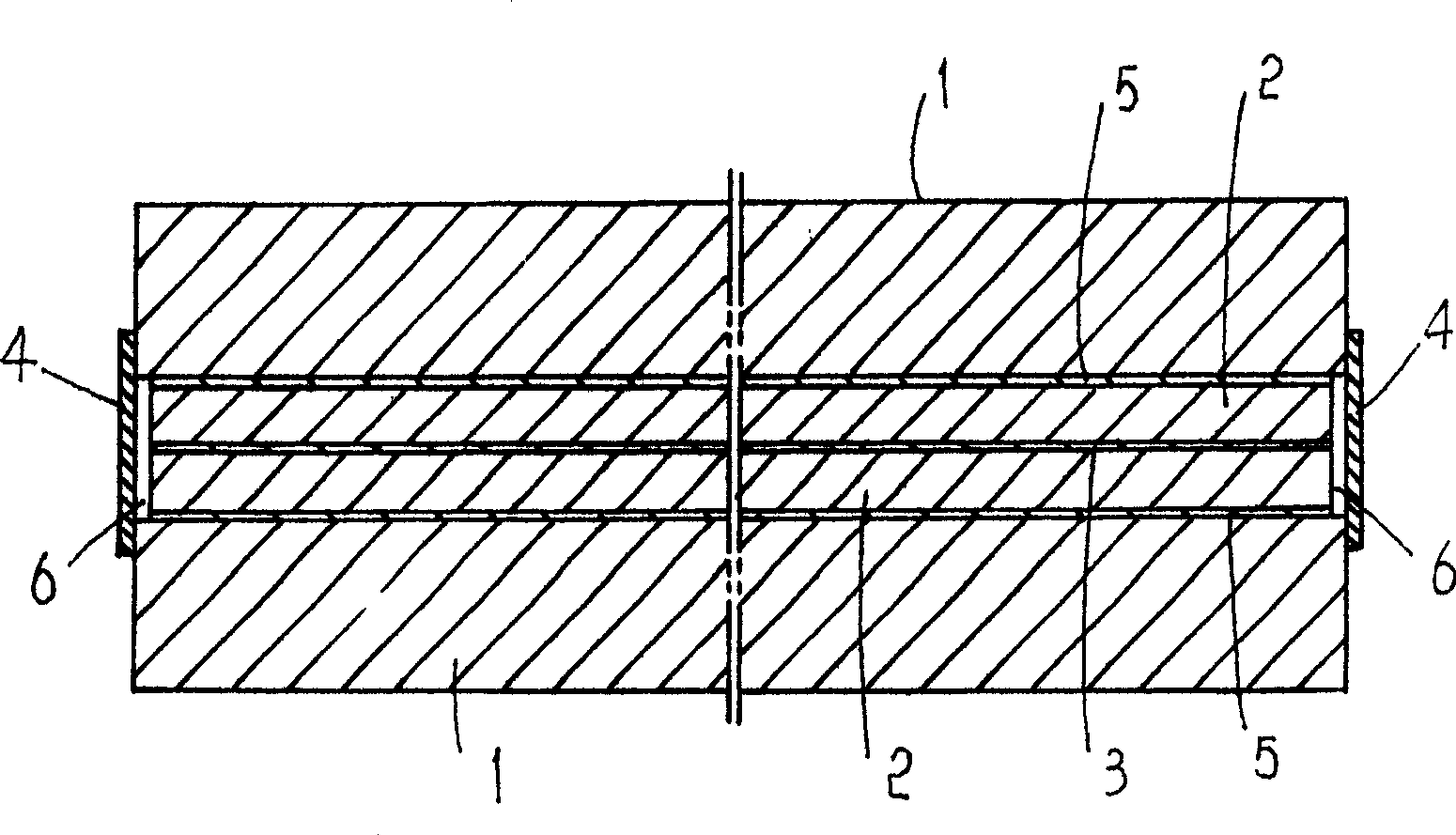

[0024] refer to figure 2 As shown in , respectively derust and decontaminate the surface of the base metal plate 1 and the clad metal plate 2 to be compounded, and then carry out billet assembly on a 500T press platform, and combine the base carbon steel plate 1 with the clad layer A 5-micron brazing material layer 5 is placed between the stainle...

Embodiment 2

[0026] Manufacture carbon steel and stainless steel composite blanks with a width of 1050mm x 800mm x a thickness of 150mm, in which the thickness of stainless steel is 10mm, and that of ordinary carbon steel is 65mm. Here, the length and width of the base metal plate are the length and width of the composite billet. First, select two base Q235 carbon steel plates with a size of 1050mm×800mm×65mm. , The extension gap in the width direction is 5mm×2, and the size of the two clad 304 stainless steel plates is 1040mm×790mm×10mm.

[0027] refer to figure 2 As shown in , respectively derust and decontaminate the surface of the base metal plate 1 and the clad metal plate 2 to be compounded, and then carry out billet assembly on a 500T press platform, and combine the base carbon steel plate 1 with the clad layer A 5-micron brazing material layer 5 is placed between the stainless steel plates 2, and light magnesium oxide superfine powder is placed between the two-layer clad stainles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com