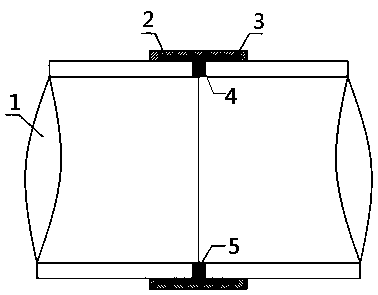

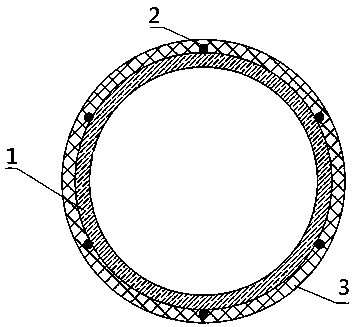

Connection method for installation of large-diameter pipe

A technology of pipeline installation and connection method, which is applied in the direction of non-removable pipe connection, pipeline laying and maintenance, pipe/pipe joint/pipe fitting, etc. problems, to achieve the effect of reducing the amount of welding engineering, reducing welding workload, reducing interference and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] Puji River inverted siphon diversion project:

[0063] 1) Project profile:

[0064] The Puji River Canal Inverted Siphon Project is located in Xinzhuang Village, Zhongzhan District, Jiaozuo City, Henan Province. It is 200m away from Jiaozuo City South Road, and the project area is connected with it by a cement road. The Puji River is a artificially treated flood discharge and sewage channel. The design pile number for the starting point of the inverted siphon inlet is Ⅳ33+798.7, and the design pile number for the exit end is Ⅳ34+131.7. Reinforced concrete box structure is adopted, and the single hole size is 6.5m×6.75m (width×height).

[0065] The Puji River is a tributary of the Wei River system in the Haihe River Basin, flowing through Jiaozuo urban area from north to south, and the ground elevation of the intersection with the inverted siphon of the Puji River is about 104-107m. The Puji River inverted siphon project is to pass through the Puji River and Puji Road...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com