Bicomponent normal temperature crosslinked aqueous organosilicon rubber waterproof paint and method for preparing same

A silicone rubber, room temperature cross-linking technology, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve problems such as poor crack resistance and difficult preparation technology, and achieve excellent hydrophobicity , Good crack resistance, good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

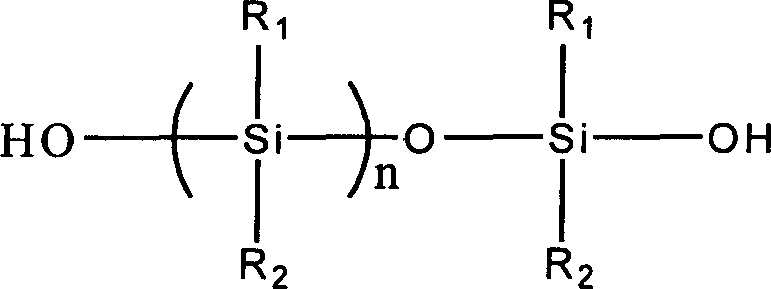

Method used

Image

Examples

Embodiment 1

[0037] In parts by weight, add 5 parts of superfine silica to 10 parts of 30% by weight silica sol, and after dispersion and mixing, add 100 parts of silicone rubber latex with a solid content of 20%, and then add 0.2 Part of dibutyltin dilaurate, stirred for 30 minutes, and mixed evenly to prepare component A. Component B was prepared by mixing 0.2 parts of ethyl orthosilicate (tetraethoxysilane) and 1.2 parts of gamma-aminopropyltriethoxysilane. When in use, calculated by weight percentage, the usage amount of component B is 1.5% of component A, slowly add component B into component A under the condition of stirring, and continue to stir for 30 minutes. Mix evenly to prepare water-based silicone rubber waterproof coating crosslinked at room temperature. After testing, the performance parameters of the two-component room temperature crosslinking and curing waterborne silicone rubber waterproof coating are shown in Table 1.

[0038] The obtained two-component room temperatur...

Embodiment 2

[0042] In parts by weight, add 10 parts of superfine calcium carbonate, 20 parts of fumed silica and 7 parts of iron oxide yellow into 15 parts of water, and after dispersing and mixing evenly, add 100 parts of 50% silicone rubber latex, and then add 1.5 parts of stannous octoate, stirred for 30 minutes, and mixed evenly to obtain component A. Component B was prepared by mixing 2 parts of methyl tributylketoxime silane and 0.2 part of γ-glycidyl etheroxypropyl trimethoxysilane. When in use, calculated by weight percentage, the usage amount of component B is 6% of component A, slowly add component B to component A under the condition of stirring, continue to stir for 40 minutes, and mix well to obtain room temperature cross Linked water-based silicone rubber waterproof coating. After testing, the performance parameters of the two-component room temperature crosslinking and curing waterborne silicone rubber waterproof coating are shown in Table 2.

[0043] The obtained two-com...

Embodiment 3

[0046] In parts by weight, 15 parts of precipitated silica, 5 parts of fumed silica and 10 parts of red iron oxide were added to 25 parts of water, after high-speed dispersion and mixing, 100 parts of 60% silicone rubber latex were added, and then Add 1.0 parts of dibutyltin oxide, stir for 10 minutes, and mix well to obtain Component A. Component B was prepared by mixing 0.2 parts of methyltributanoximinosilane and 3.6 parts of gamma-aminopropyltriethoxysilane. When in use, calculated by weight percentage, the usage amount of component B is 4% of component A, slowly add component B to component A under the condition of stirring, continue to stir for 40 minutes, and mix well to obtain room temperature cross Linked water-based silicone rubber waterproof coating. After testing, the performance parameters of the two-component room temperature crosslinking and curing waterborne silicone rubber waterproof coating are shown in Table 3.

[0047] The obtained two-component room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com