Polylactic acid alloy membrane and application thereof

A technology of alloy film and polylactic acid, which is applied in the direction of coating, etc., can solve the problems of unfavorable environmental protection, toxicity of diisocyanate, and affecting the effect of diisocyanate chain extension, etc., to promote wide application, simple process method, and improve oxygen barrier performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

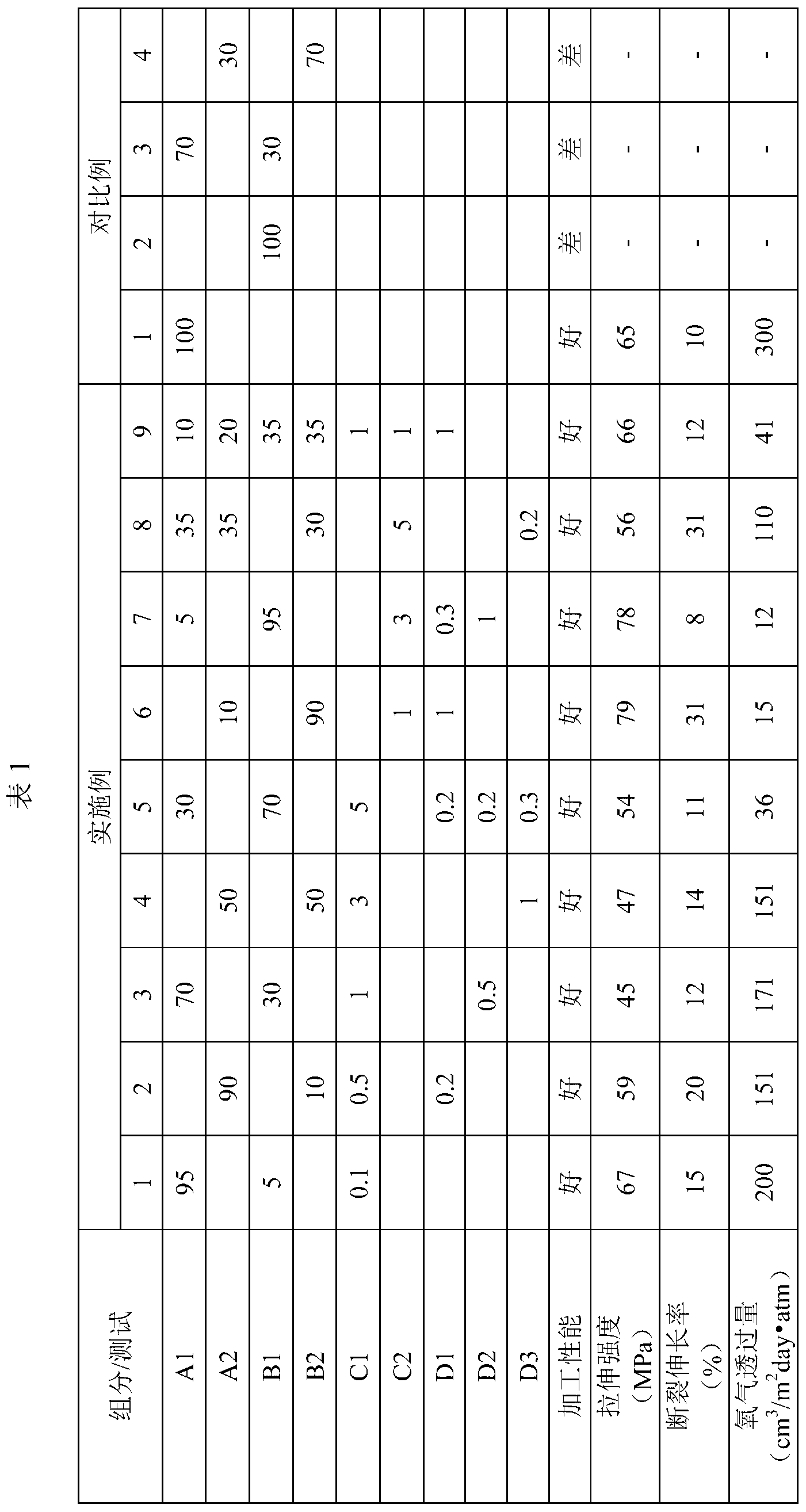

Embodiment 1~9

[0036] Table 1 shows the formulations and performance evaluations of the polylactic acid alloy film Examples 1-9. After preliminarily mixing the components shown in Table 1, extrude with a twin-screw at a temperature of 190°C, water-cool and pelletize; after the particles are dried, extrude and blow mold with a single-screw extruder at 180°C. A thin film with a thickness of 20 μm was prepared.

[0037] Wherein, the content of each formula is parts by weight, and various components are as follows:

[0038] (A) Polylactic acid resin

[0039] A1: Natureworks, USA, 4032D

[0040] A2: Natureworks, USA, 4060D

[0041] (B) Polyvinyl alcohol resin

[0042] B1: Shanghai Petrochemical, polymerization degree 1700, alcoholysis degree 99%

[0043] B2: Shanghai Petrochemical, polymerization degree 1700, alcoholysis degree 88%

[0044] (C) Compatibilizer

[0045] C1: BASF Corporation, Joncyrl ADR4368, multi-epoxy functional polymer

[0046] C2: Sinopharm Group, maleic anhydride graft...

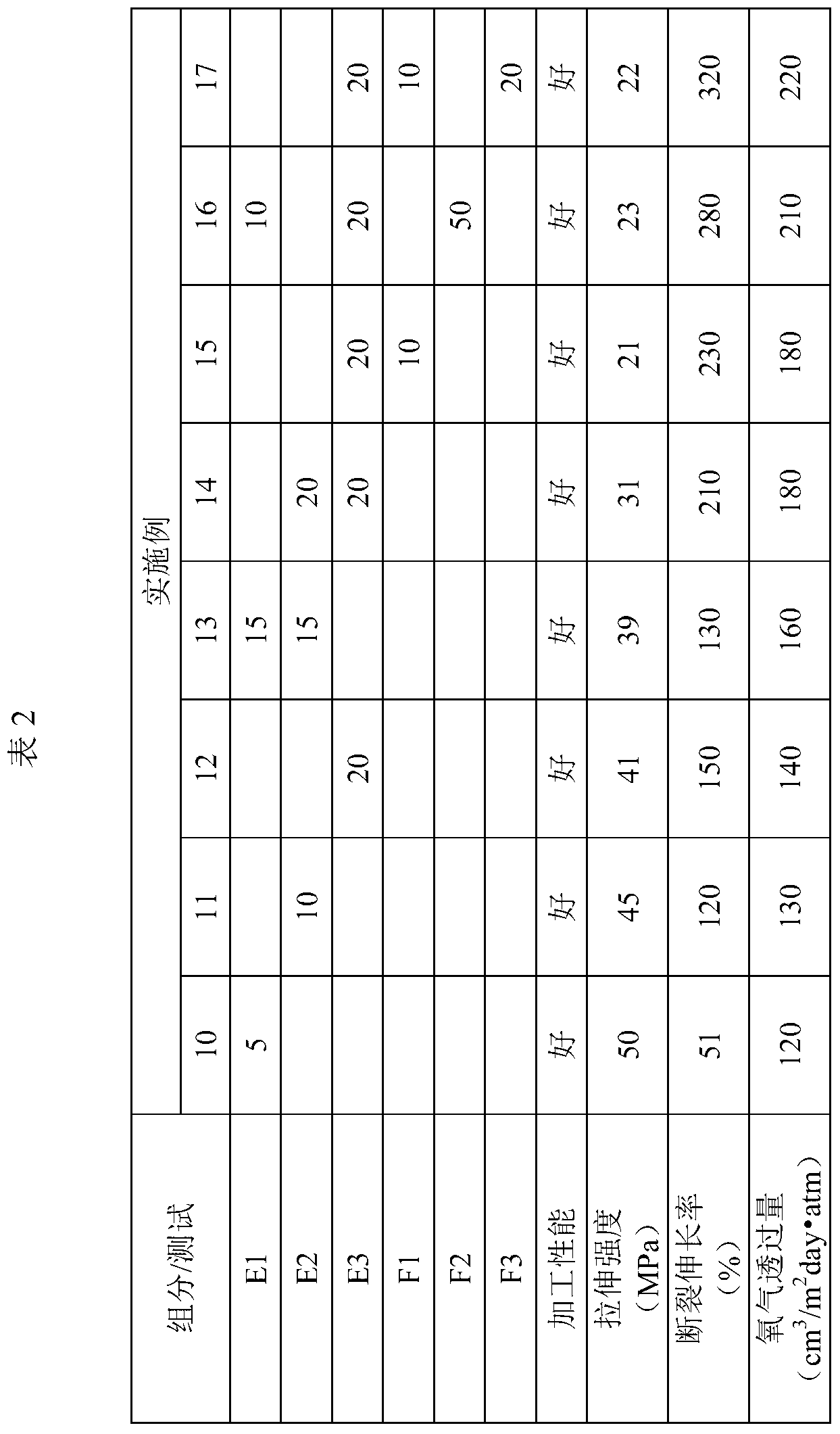

Embodiment 10~17

[0061] Table 2 shows that on the basis of A1 / A2 / B2 / C2 / D2 / D3 being 35 / 35 / 30 / 5 / 0.2 / 0.2 parts by weight in Table 1, after further adding the components shown in Table 2 The formulation and performance evaluation of the embodiments 10-17. The components shown in Table 2 were preliminarily mixed, extruded with a twin-screw at an extrusion temperature of 190° C., and cast to prepare a film with a thickness of 20 μm.

[0062] Wherein, the content of each formula is parts by weight, and various components are as follows:

[0063] (E) Plasticizer

[0064] E1: Sinopharm Group, n-Butyl Acetyl Citrate

[0065] E2: Sinopharm Group, glycerin

[0066] E3: Sinopharm Group, polyethylene glycol, number average molecular weight 1000

[0067] (F) toughening agent

[0068] F1: BASF Corporation, Ecoflex7011, polybutylene terephthalate adipate

[0069] F2: Japan Showa Polymer Co., Ltd., Bionolle3001, polybutylene succinate adipate

[0070] F3: DuPont, Biomax Strong100, ethylene-acrylic acid c...

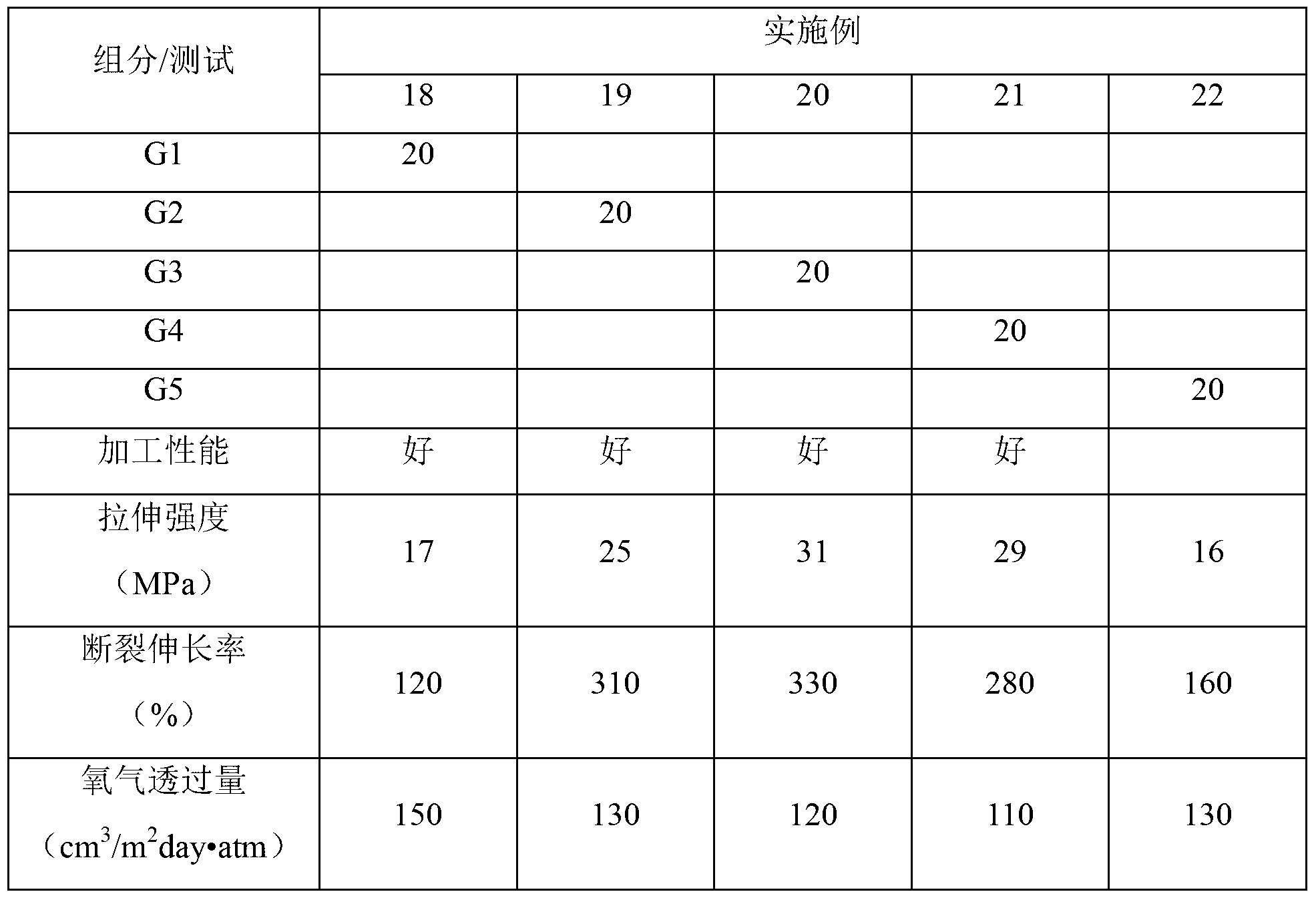

Embodiment 18~22

[0077] Table 3 shows that on the basis of A1 / A2 / B2 / C2 / D2 / D3 being 35 / 35 / 30 / 5 / 0.2 / 0.2 / parts by weight respectively in Table 1, adding Table 2 is respectively 20 / 10 After adding E3 / F1 in parts by weight, the formulations and performance evaluations of Examples 18-22 were further added according to the components shown in Table 3. The components shown in Table 3 were preliminarily mixed, extruded by twin-screws at an extrusion temperature of 190° C., and cast to prepare a film with a thickness of 20 μm.

[0078] Wherein, the content of each formula is parts by weight, and various components are as follows:

[0079] (G) filler

[0080] G1: Zibo Shengxu Industry and Trade Co., Ltd., micron grade calcium carbonate, D50=2~2 microns.

[0081] G2: Ruicheng Xintai Nano Materials Co., Ltd., nano-scale calcium carbonate, D50=15-25 nm.

[0082] G3: Glycerin surface-modified nano-scale calcium carbonate, self-made, 1kg G2 and 100g glycerin were added to the reaction kettle, heated to 80°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com