Polypropylene/polyvinylidene fluoride blended modified material and preparation method thereof

A polyvinylidene fluoride and blending modification technology, which is applied in the field of polypropylene/polyvinylidene fluoride blending modified material and its preparation, can solve the problems of low low temperature impact strength, growth of microorganisms and algae, poor cold resistance, etc. Achieve excellent weather resistance, reduce oxygen transmission rate, and expand the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

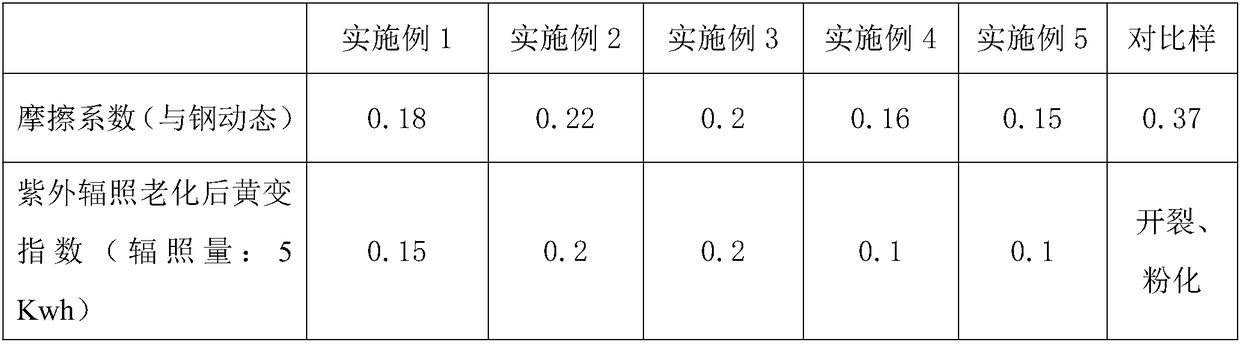

[0020] In order to make the object of the present invention, technical scheme and advantage clearer, the present invention will be further described below in conjunction with embodiment:

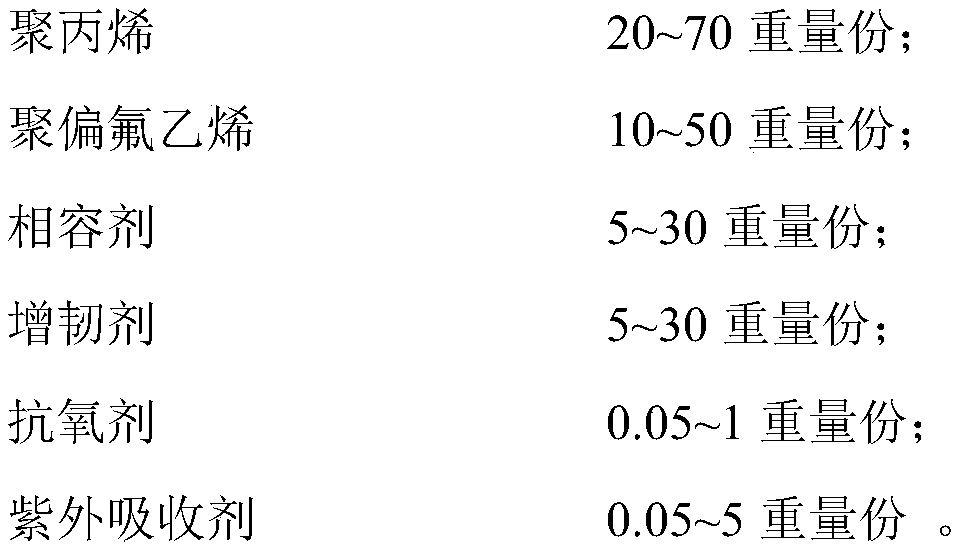

[0021] Embodiment 1-5 is five kinds of different modified material formulations (referring to Table 1). The raw materials adopted in each embodiment are as follows:

[0022] (1) Polypropylene: homopolypropylene brand is B8101, the supplier is: Yanshan Petrochemical, the melt index is 0.36 (g / 10min, 2.16kg, 230 ℃);

[0023] (2) Polyvinylidene fluoride: the grade is 1000HD, the supplier is Arkema, France; the melt index is 1.1 (g / 10min, 5kg, 230°C).

[0024] (3) Compatibilizer: maleic anhydride grafted polypropylene, grade 9801, supplier: Jiayirong.

[0025] (4) Toughening agent: polyolefin elastomer, grade DF610, supplier: Mitsui Chemicals.

[0026] (5) Antioxidant: hindered phenolic antioxidant, trade name: antioxidant-1098 and antioxidant-1010, the two are mixed according to the ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com