Chestnut shell extract-containing soy protein isolate-based film and preparation method thereof

A technology of soybean protein isolate and chestnut shell, applied in the field of soybean protein isolate film and its preparation, can solve the problems of low strength of soybean protein isolate film, achieve good mechanical properties, improve utilization rate, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

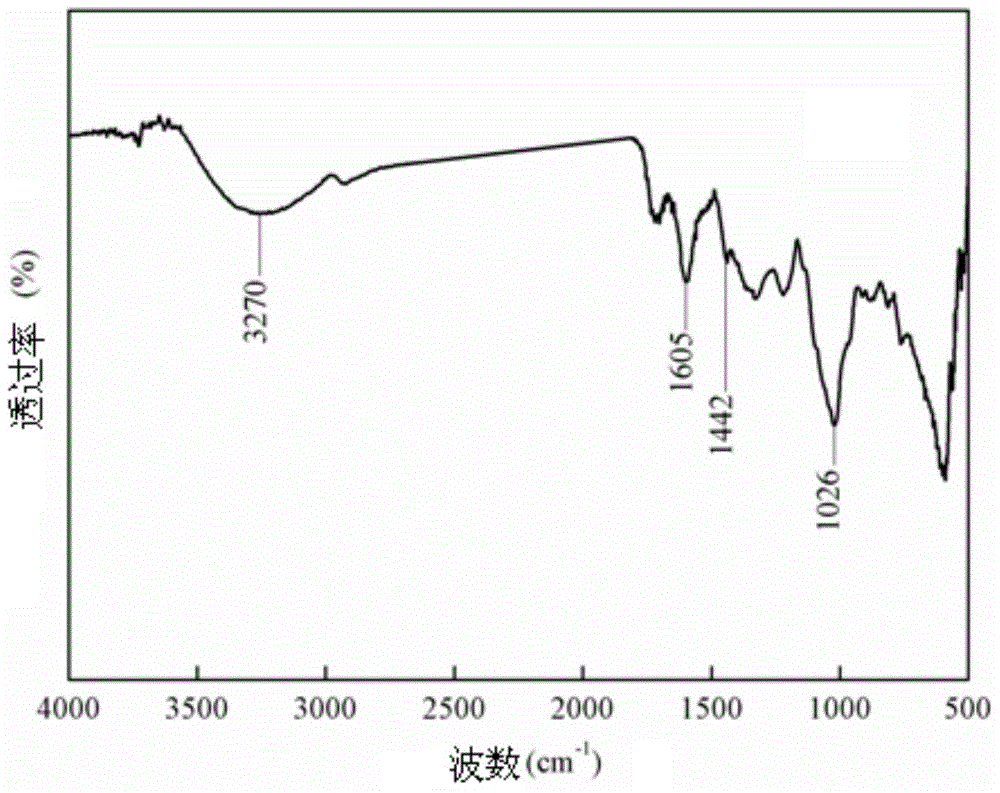

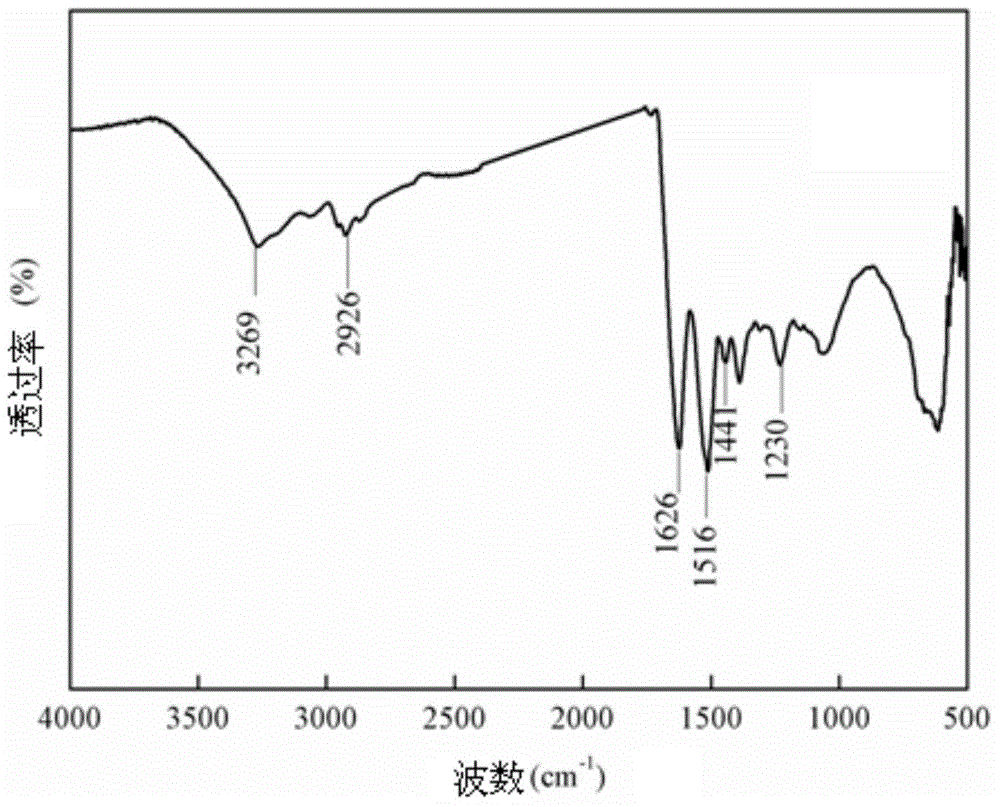

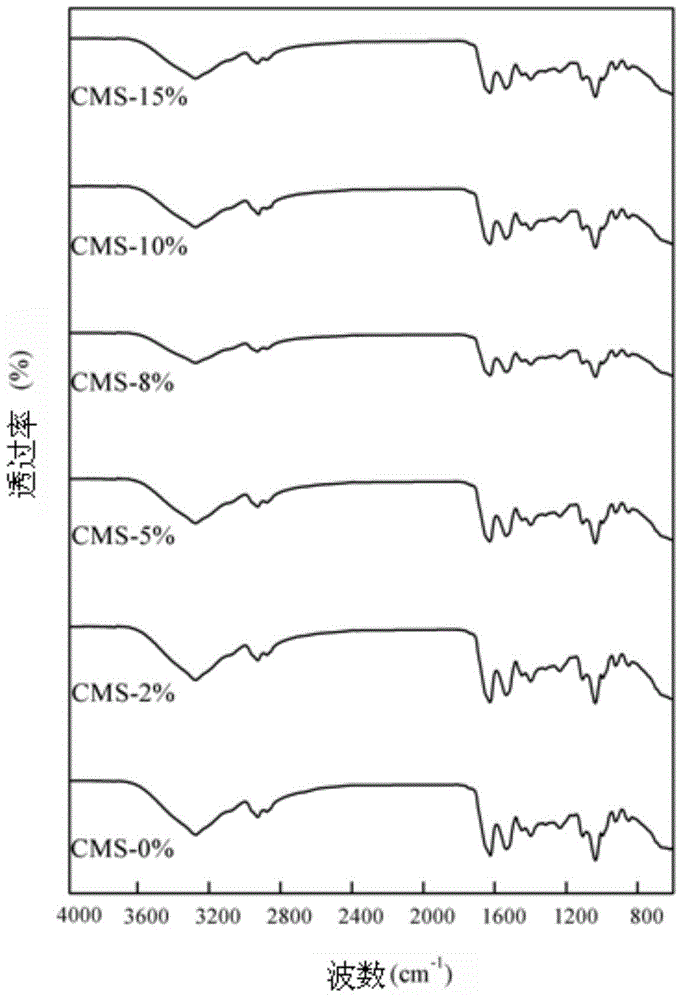

[0021] Specific embodiment one: the soybean protein isolate film containing chestnut shell extract of the present embodiment is made of soybean protein isolate powder, chestnut shell extract and glycerin, wherein the quality of chestnut shell extract is 2 times that of soybean protein isolate powder % to 15%, and the quality of glycerin is 10% to 30% of the soybean protein isolate powder.

[0022] The soy protein isolate film containing chestnut shell extract in this embodiment is a flexible and transparent film with certain tensile strength and good elongation, and can absorb ultraviolet light and has certain oxidation resistance.

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment differs from Embodiment 1 in that the quality of the chestnut shell extract is 3% to 8% of the soybean protein isolate powder, and the quality of glycerin is 15% to 20% of the soybean protein isolate powder. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Specific embodiment three: the preparation method of the soybean protein isolate film that contains chestnut shell extract described in specific embodiment one, carry out according to the following steps:

[0025] 1. After the chestnut shell is crushed, put the chestnut shell powder into water according to the weight percentage of chestnut shell and water as 1:8-15, heat to 80-100°C and stir for 1-2 hours; Centrifuge and separate with a centrifuge, add the supernatant to a rotary evaporator and concentrate until the solution is viscous, and then place it in a vacuum drying oven to dry to constant weight to obtain chestnut shell extract;

[0026] 2. Weigh soybean protein isolate powder, chestnut shell extract and glycerin, wherein the quality of chestnut shell extract is 2% to 15% of soybean protein isolate powder, and the quality of glycerin is 10% to 30% of soybean protein isolate powder; Dissolve soybean protein isolate powder in water to obtain a protein solution; ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com