High-resistance antibacterial PE (polyethylene) film and preparation method thereof

A high-barrier, nano-technology, applied in the field of high-barrier antibacterial PE film and its preparation, can solve the problems of poor barrier antibacterial effect, etc., achieve good barrier properties, improve antibacterial properties and barrier properties, and broaden the application effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

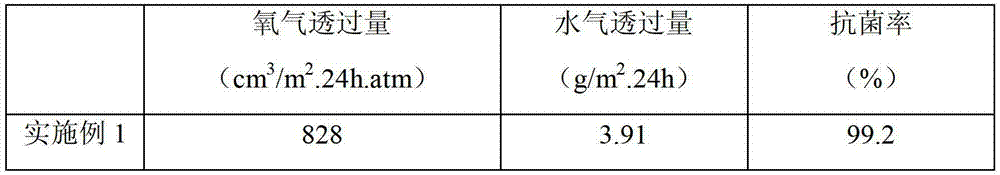

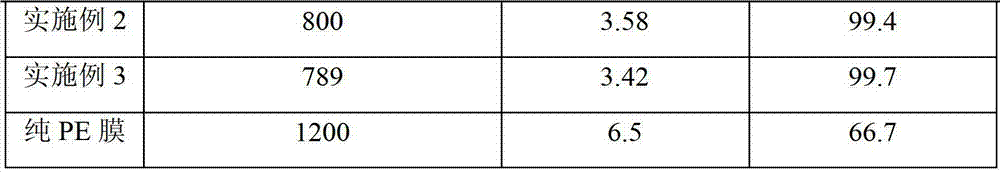

Examples

Embodiment 1

[0024] In this embodiment, the high-barrier antibacterial PE film is that the nanocomposite modified masterbatch is added to the LDPE matrix resin, and the high-barrier antibacterial PE film is obtained by extrusion blow molding; the quality of the nanocomposite modified masterbatch is the LDPE matrix 5% of resin mass. The ratio of each component is:

[0025] 100 parts of LDPE, 6.0 parts of nano ZnO, 20 parts of montmorillonite, 20 parts of maleic anhydride grafted polyethylene;

[0026] Its preparation method is as follows:

[0027] 1) First disperse 20 parts by mass of montmorillonite in 1mol L -1 In the zinc chloride aqueous solution, the solid-to-liquid ratio is 1g / 10ml, stirred at a constant temperature of 65°C for 4h, filtered and washed repeatedly until there is no zinc ion in the filtrate, dried by blasting at 80°C for 24h, then put into a muffle furnace for drying at 400°C Bake for 2 hours to obtain montmorillonite loaded with nano-ZnO with a loading capacity of 30...

Embodiment 2

[0033] In this embodiment, the high-barrier antibacterial PE film is that the nanocomposite modified masterbatch is added to the LDPE matrix resin, and the high-barrier antibacterial PE film is obtained by extrusion blow molding; the quality of the nanocomposite modified masterbatch is the LDPE matrix 3% of resin mass. The ratio of each component is:

[0034] 100 parts of LDPE, 8.0 parts of nano ZnO, 30 parts of montmorillonite, 30 parts of maleic anhydride grafted polyethylene;

[0035] Its preparation method is as follows:

[0036] 1) Disperse 30 parts by mass of montmorillonite in 1mol L -1 In the zinc chloride aqueous solution, the solid-to-liquid ratio is 1g / 10ml, stirred at a constant temperature of 65°C for 4h, filtered and washed repeatedly until there is no zinc ion in the filtrate, dried by blasting at 80°C for 24h, then put into a muffle furnace for drying at 400°C Bake for 2 hours to obtain montmorillonite loaded with nano-ZnO with a loading capacity of 27%.

...

Embodiment 3

[0042] In this embodiment, the high-barrier antibacterial PE film is that the nanocomposite modified masterbatch is added to the LDPE matrix resin, and the high-barrier antibacterial PE film is obtained by extrusion blow molding; the quality of the nanocomposite modified masterbatch is the LDPE matrix 8% of resin mass. The ratio of each component is:

[0043] 100 parts of LDPE, 3.2 parts of nano ZnO, 10 parts of montmorillonite, 10 parts of maleic anhydride grafted polyethylene;

[0044] Its preparation method is as follows:

[0045] 1) Disperse 10 parts by mass of montmorillonite in 1mol L -1 In the aqueous solution of zinc acetate, the solid-to-liquid ratio is 1g / 10ml, stirred at 65°C for 4h, filtered and washed repeatedly until there is no zinc ion in the filtrate, dried by blast at 80°C for 24h, then baked in a muffle furnace at 400°C 2h, the montmorillonite loaded with nano-ZnO was obtained with a loading of 32%.

[0046] 2) Disperse the nano-ZnO-loaded montmorillonite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com