High-barrier composite film and production method thereof

A composite film and production method technology, which is applied in the field of food packaging film and industrial stretch film, can solve the problems of high oxygen transmission rate and water vapor transmission rate of the film, and cannot meet the requirements of food hygiene and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

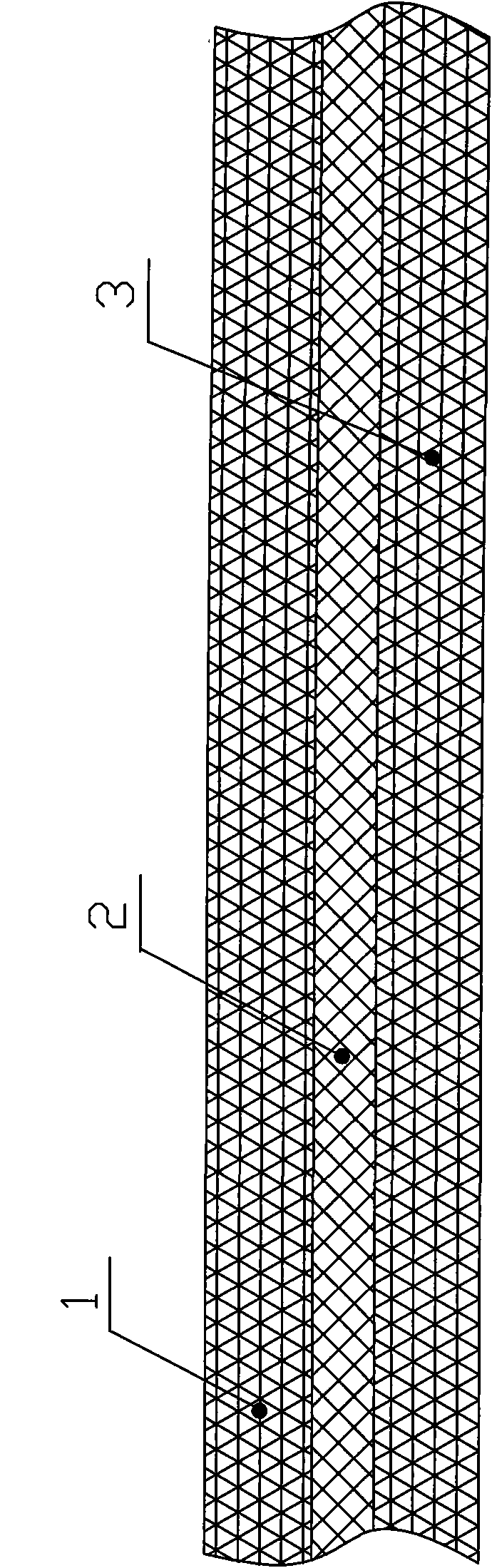

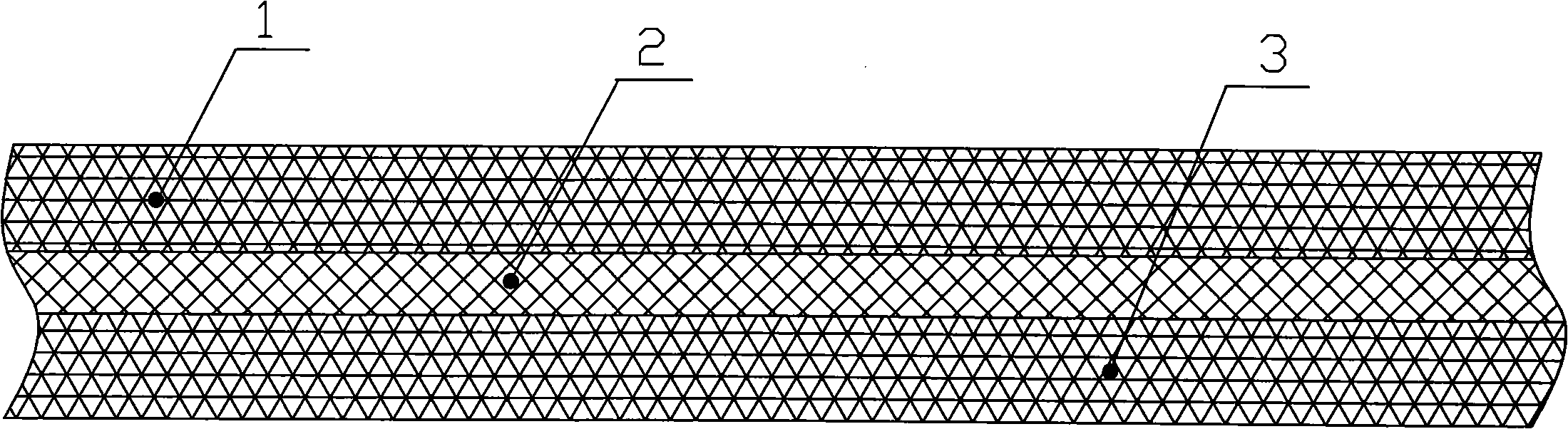

[0018] As shown in the figure, the high-barrier composite film of the present invention includes a film body, and the film body is successively composed of a low-density polyethylene (LDPE) outer layer 1, a polyvinylidene chloride (PVDC) middle layer 2 and a low-density polyethylene layer. The inner layer 3 of ethylene (LDPE) is compounded.

[0019] The high-barrier composite film of the present invention is compounded according to the following method:

[0020] Add low-density polyethylene (LDPE), polyvinylidene chloride ( PVDC) and low-density polyethylene (LDPE) pellets, the feeding speed of the three extruders is controlled within 260 rpm. When heated by the melting section of the extruder, each area of the inner and outer layers of low-density polyethylene materials The heating temperature is as follows: Zone 1: 155-170℃, Zone 2: 165-175℃, Zone 3: 165-175℃, Zone 4: 165-175℃, Zone 5: 165-175℃, Zone 6: 165- 175°C; the heating temperature of each zone of the middle polyv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com