Patents

Literature

133results about How to "The packaging method is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

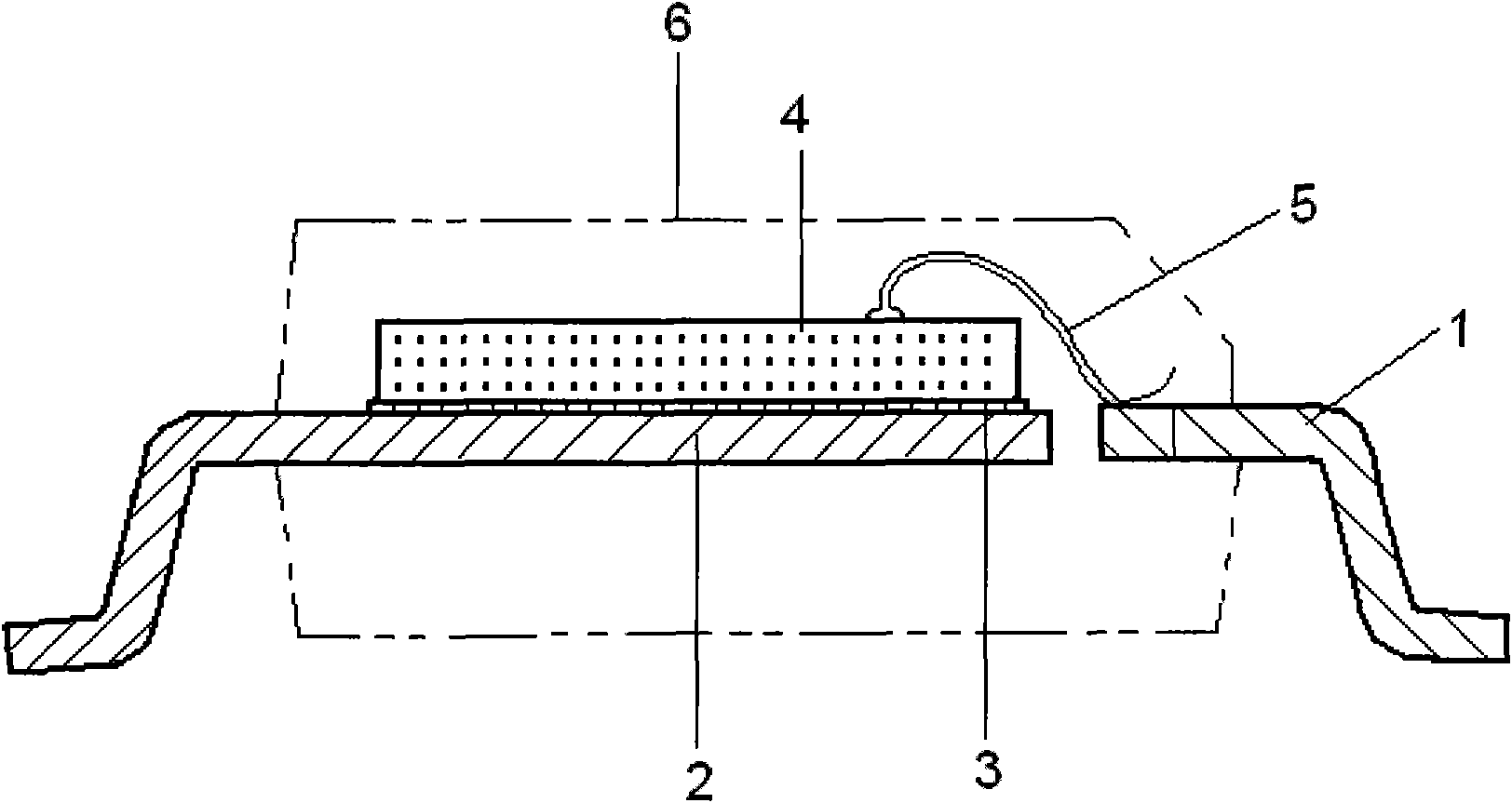

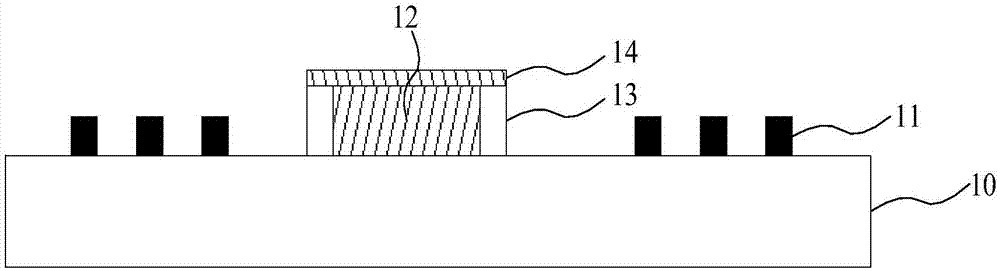

Wafer-level fingerprint recognition chip packaging structure and method

InactiveCN104201115ASimplify the packaging processReduce damageMeasurement apparatus componentsSemiconductor/solid-state device detailsFingerprintComputer science

Disclosed is a wafer-level fingerprint recognition chip packaging structure and method. The method includes: providing a substrate which comprises a plurality of induction chip areas and is provided with a first surface and a second surface opposite to the first surface, wherein a first surface of each induction chip area comprises an induction area; forming a covering layer on the first surface of the substrate; forming a plug structure in each induction chip area of the substrate, wherein one end of each plug structure is electrically connected with the corresponding induction area, and the other end of each plug structure is exposed out of the second surface of the substrate. By the forming method, the packaging process of a fingerprint recognition chip can be simplified, the requirement on sensitivity of the induction chip is lowered, and the packaging method is wider in application.

Owner:CHINA WAFER LEVEL CSP

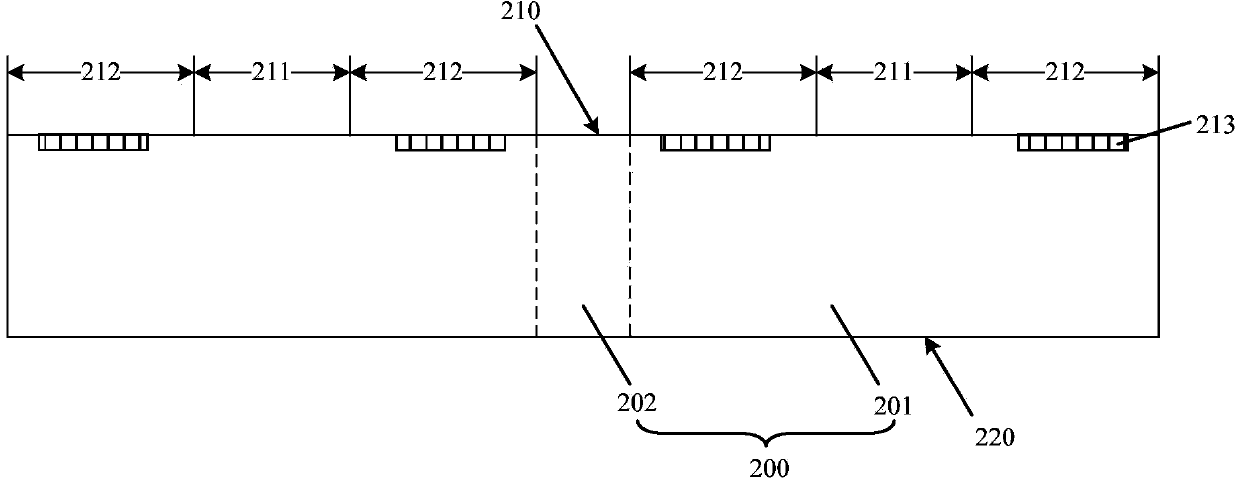

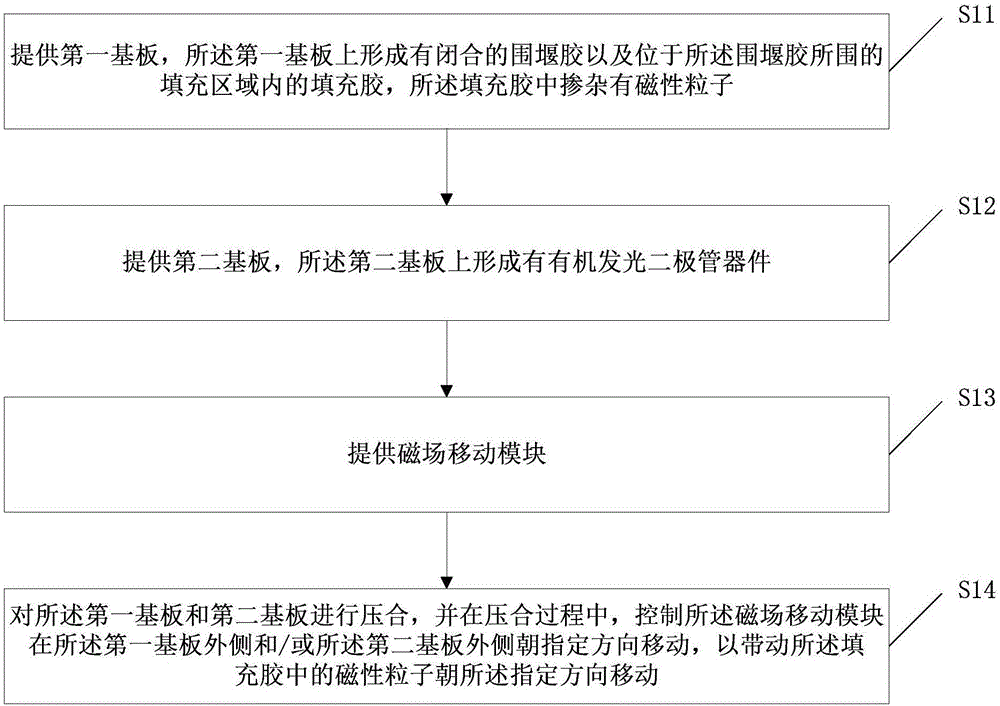

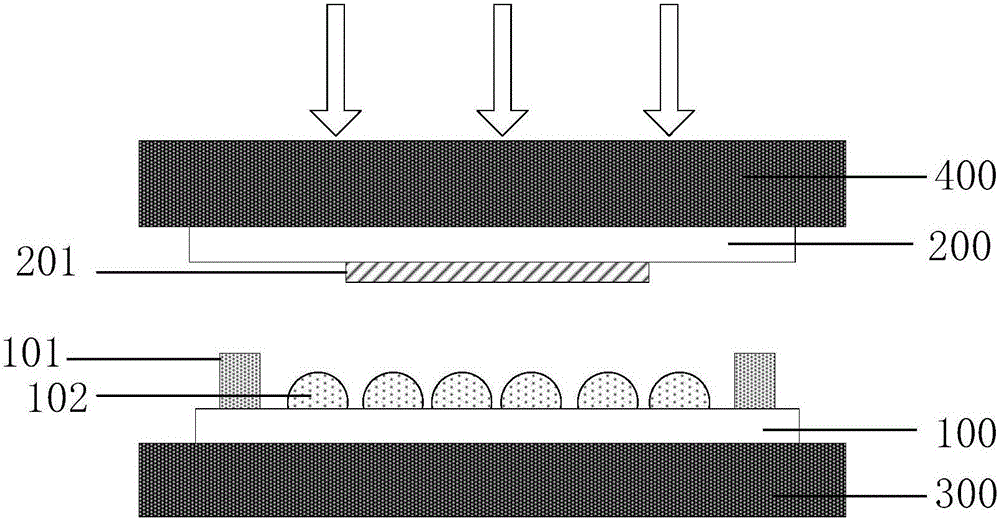

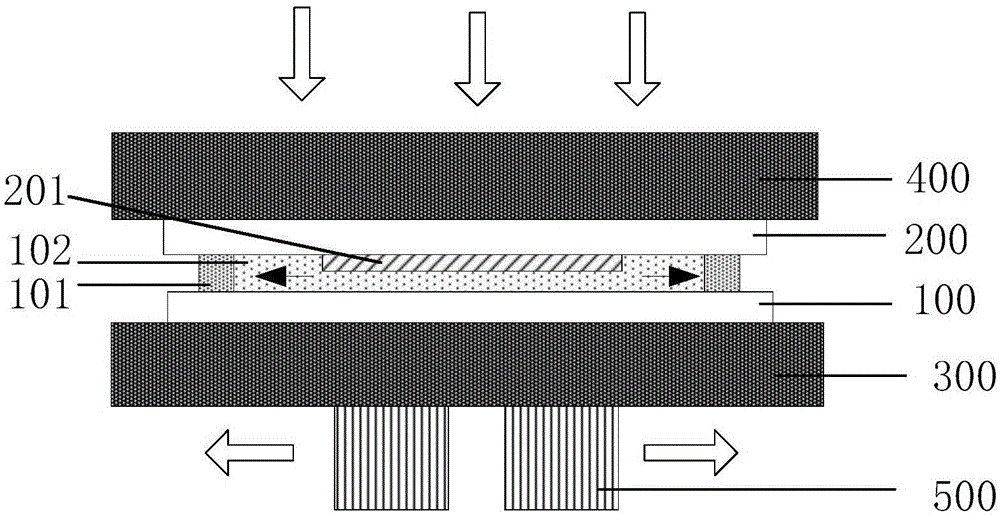

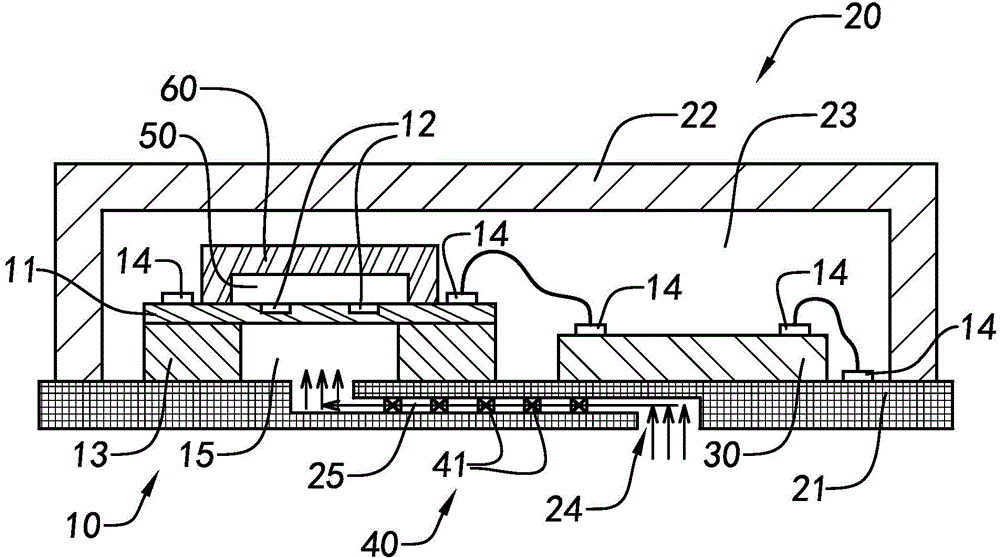

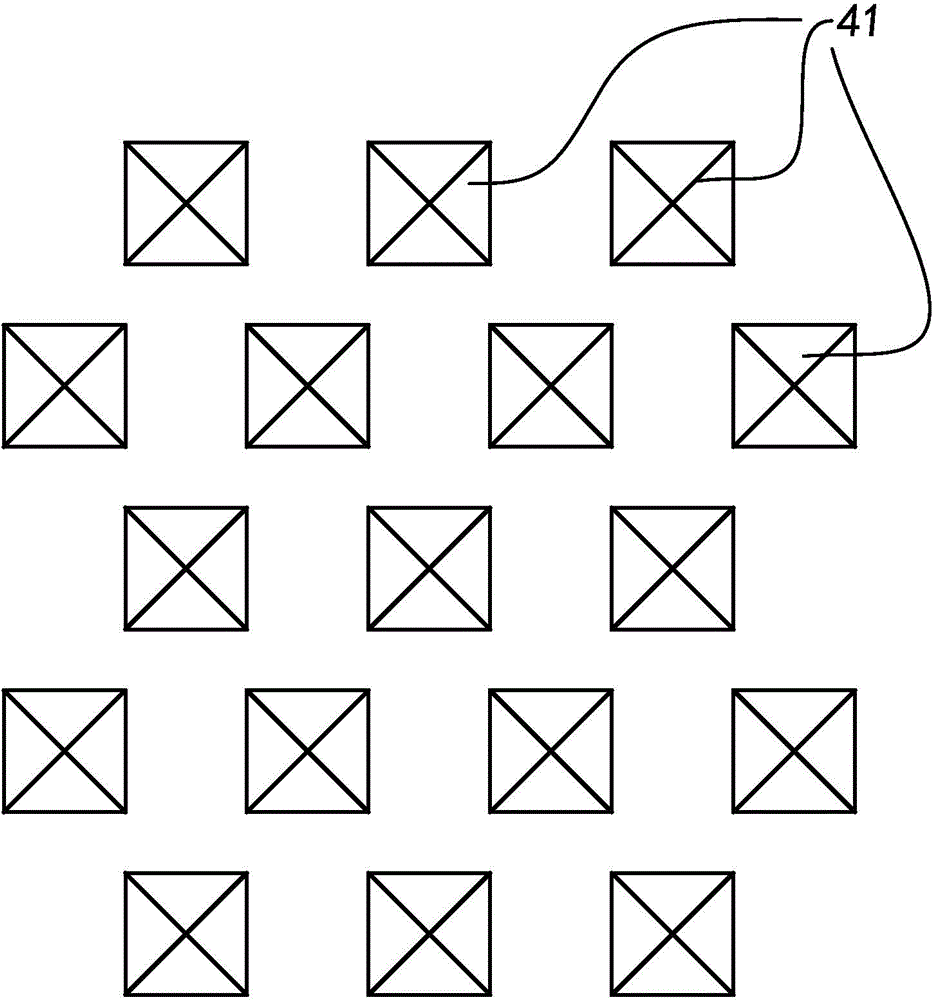

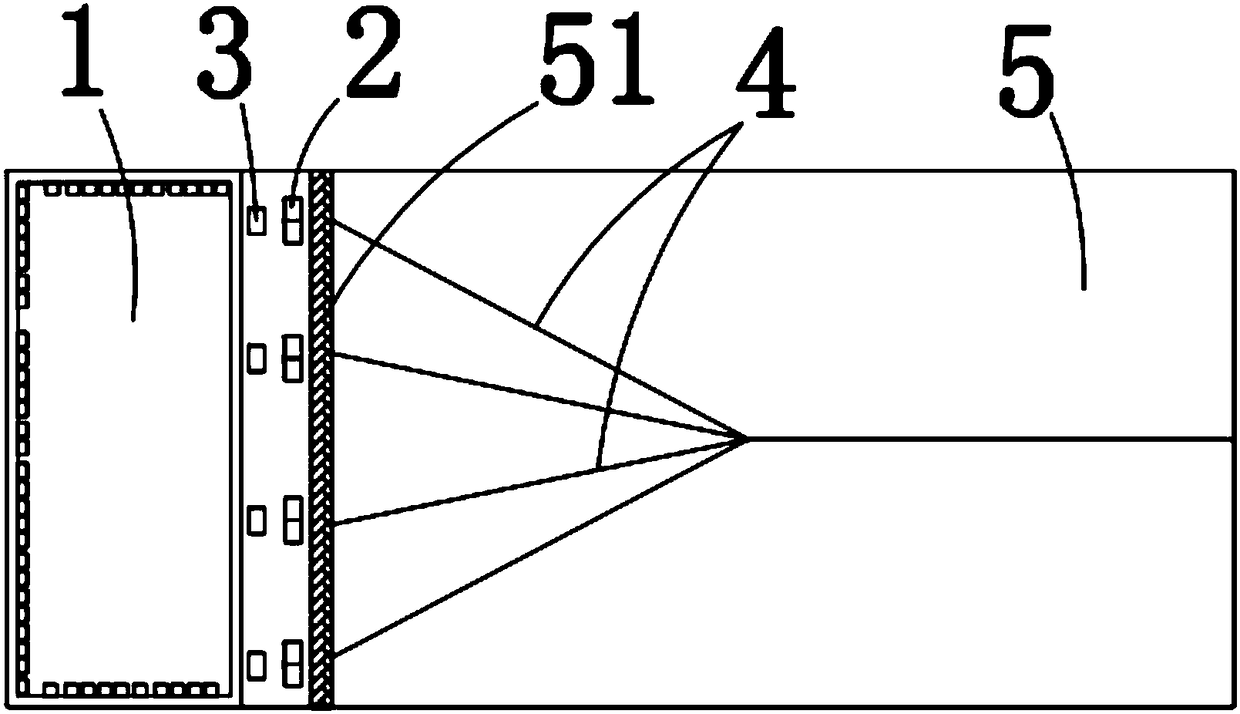

Organic light emitting diode device and packaging method and device thereof

ActiveCN106784360AImprove packaging effectSpread evenlySolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveLight-emitting diode

The invention provides an organic light emitting diode device and a packaging method and device thereof. The packaging method comprises the steps that a first substrate is provided, wherein a closed cofferdam adhesive and a filling adhesive located in the filling area defined by the cofferdam adhesive are formed on the first substrate, and the filling adhesive is doped with magnetic particles; a substrate is provided, and the organic light emitting diode device is formed on the second substrate; a magnetic field moving module is provided; the first substrate and the second substrate are pressed, the magnetic field moving module is controlled to move in the designated direction on the outer side of the first substrate and / or the second substrate so as to drive the magnetic particles in the filling adhesive to move in the designated direction, the filling adhesive is forced to be dispersed all around in the filling area, air bubbles can be extruded from the inside of the filling adhesive, and the packaging effect of the organic light emitting diode device is improved.

Owner:BOE TECH GRP CO LTD

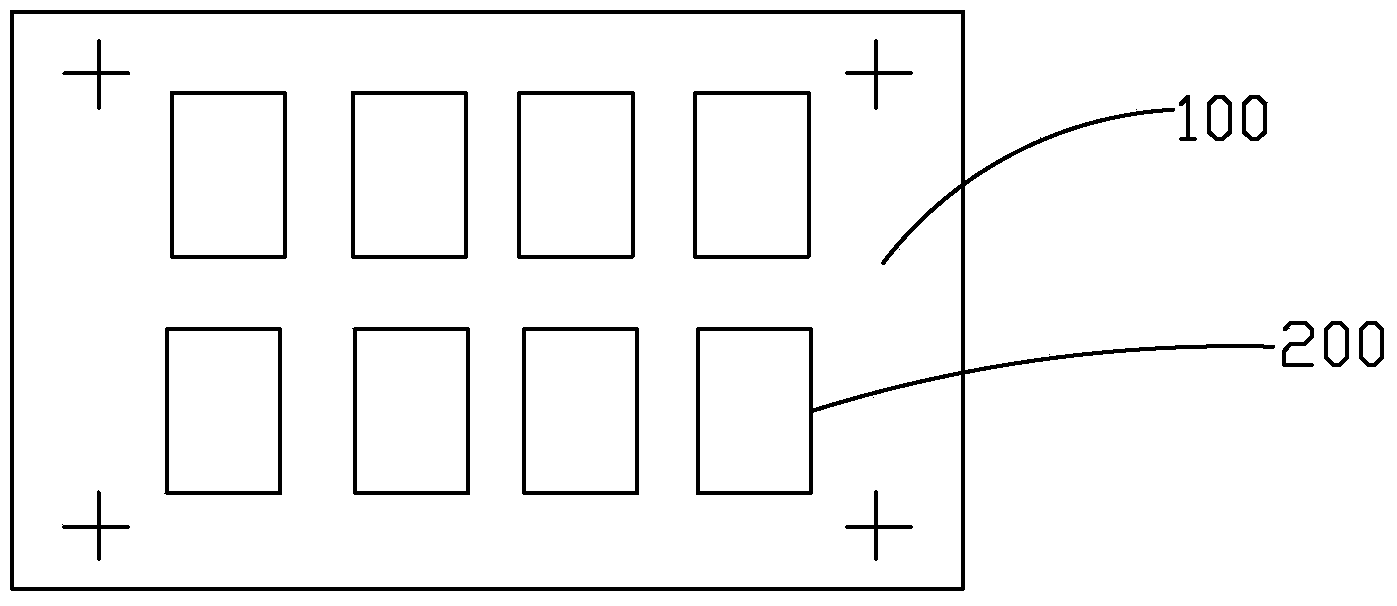

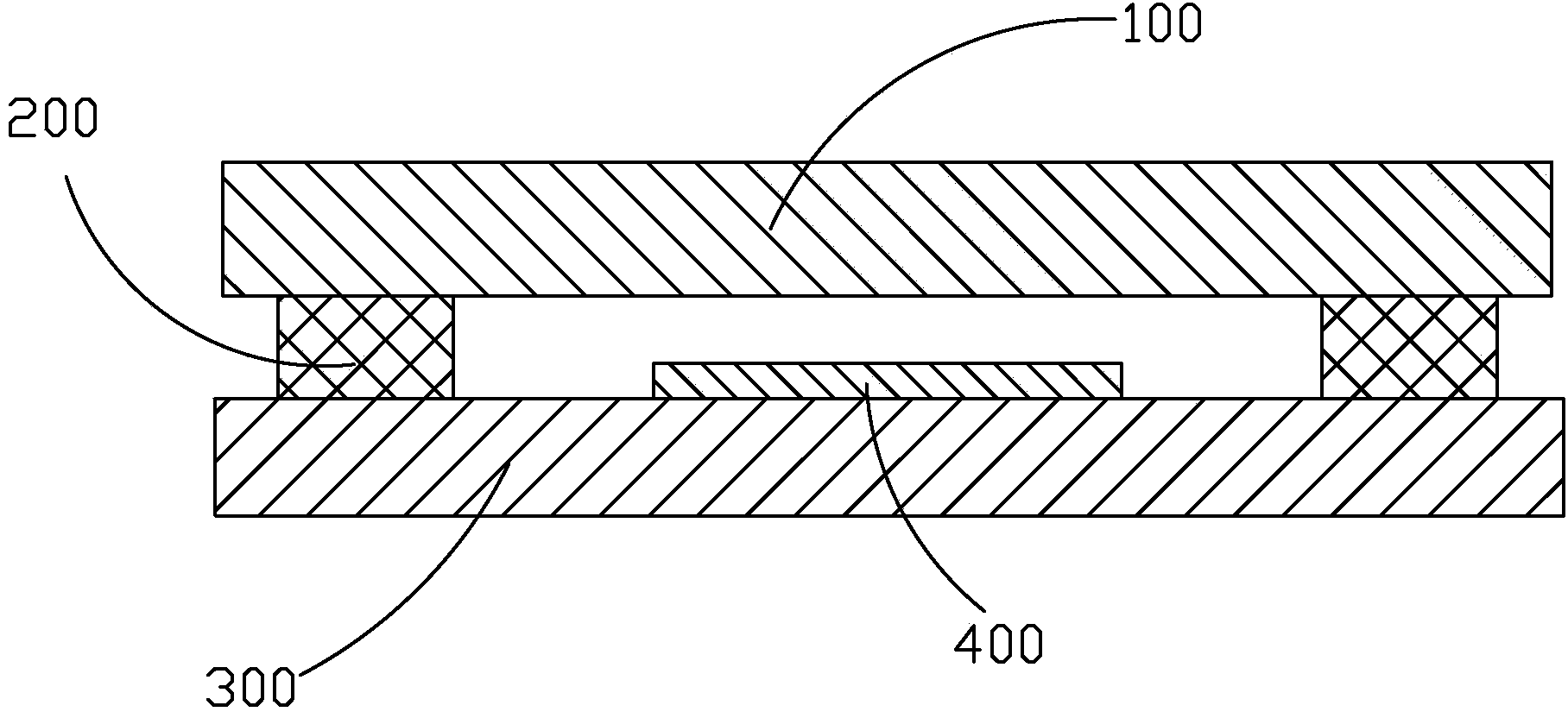

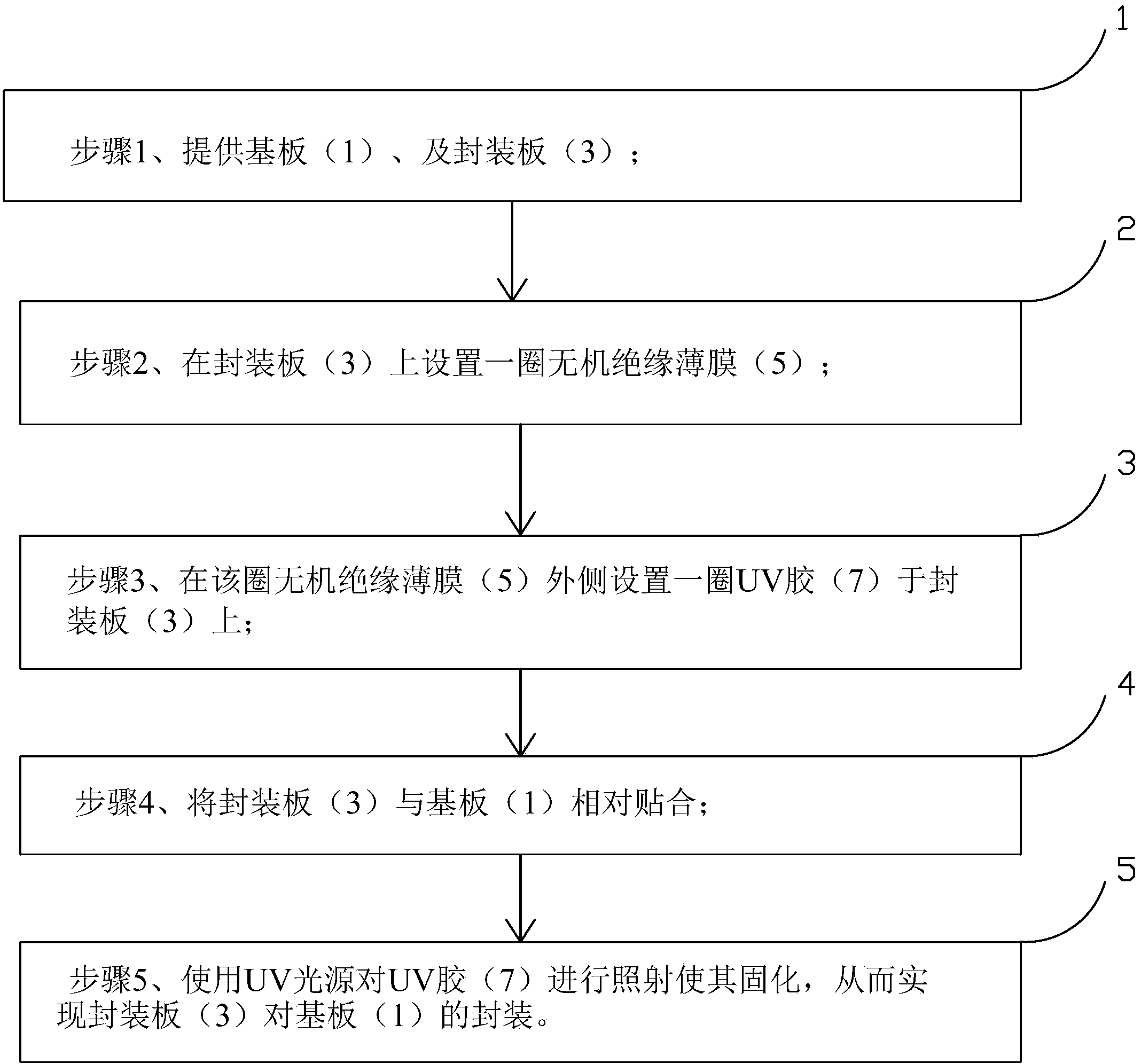

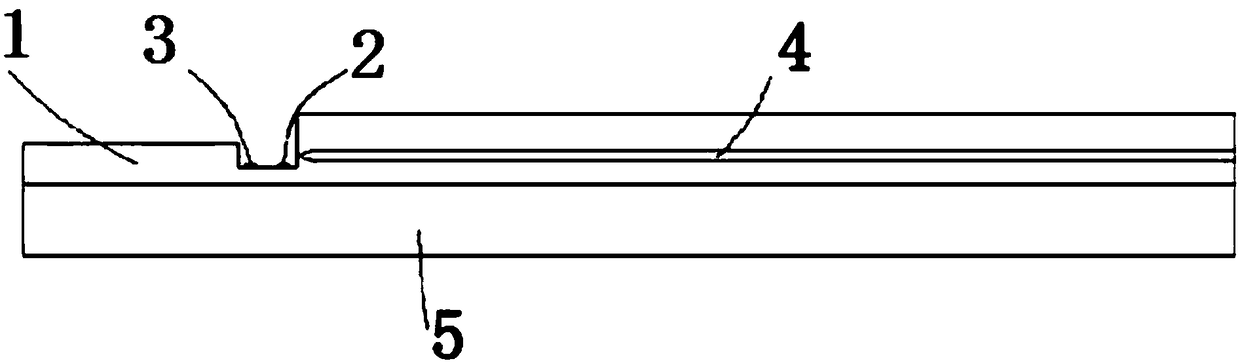

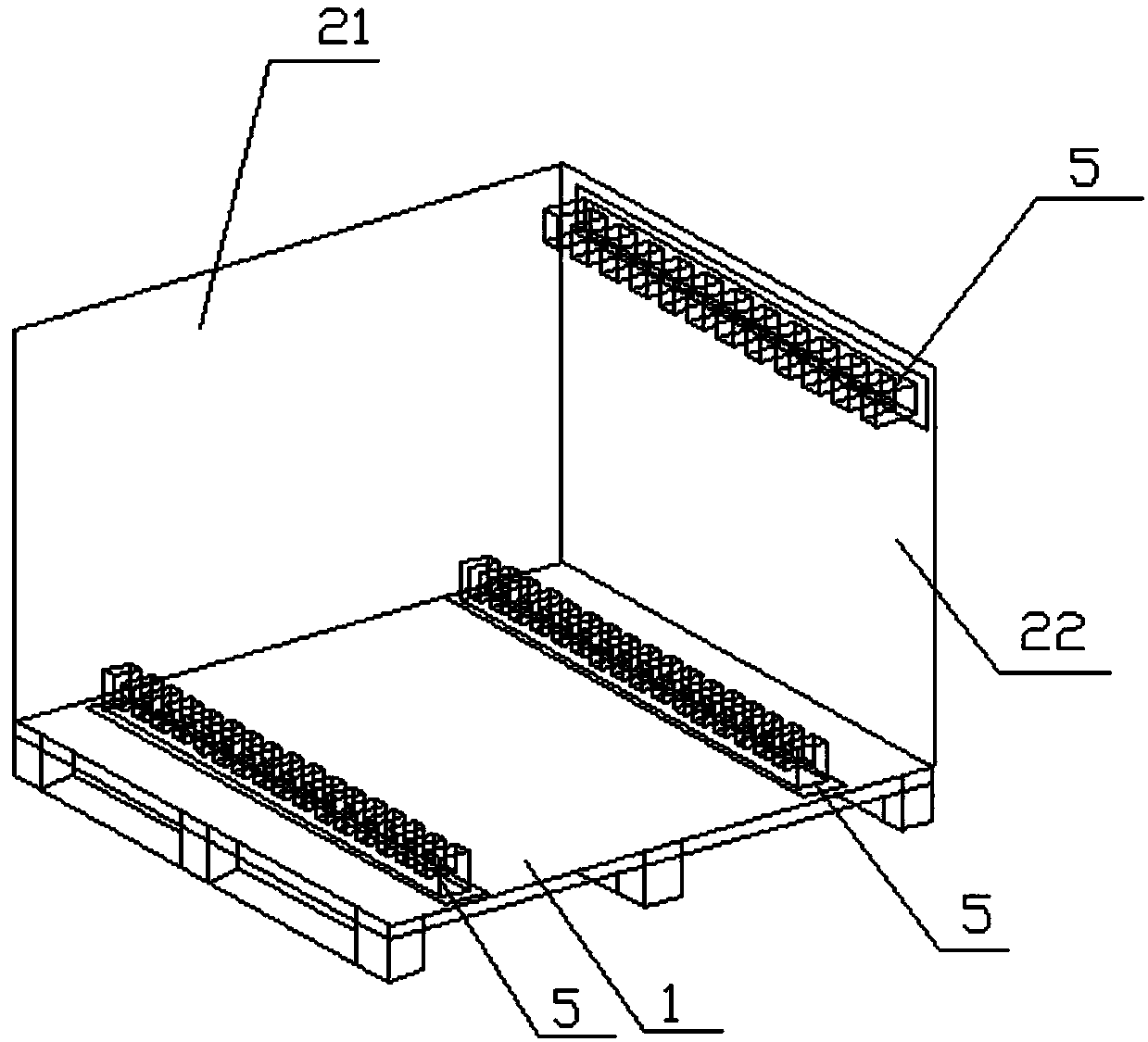

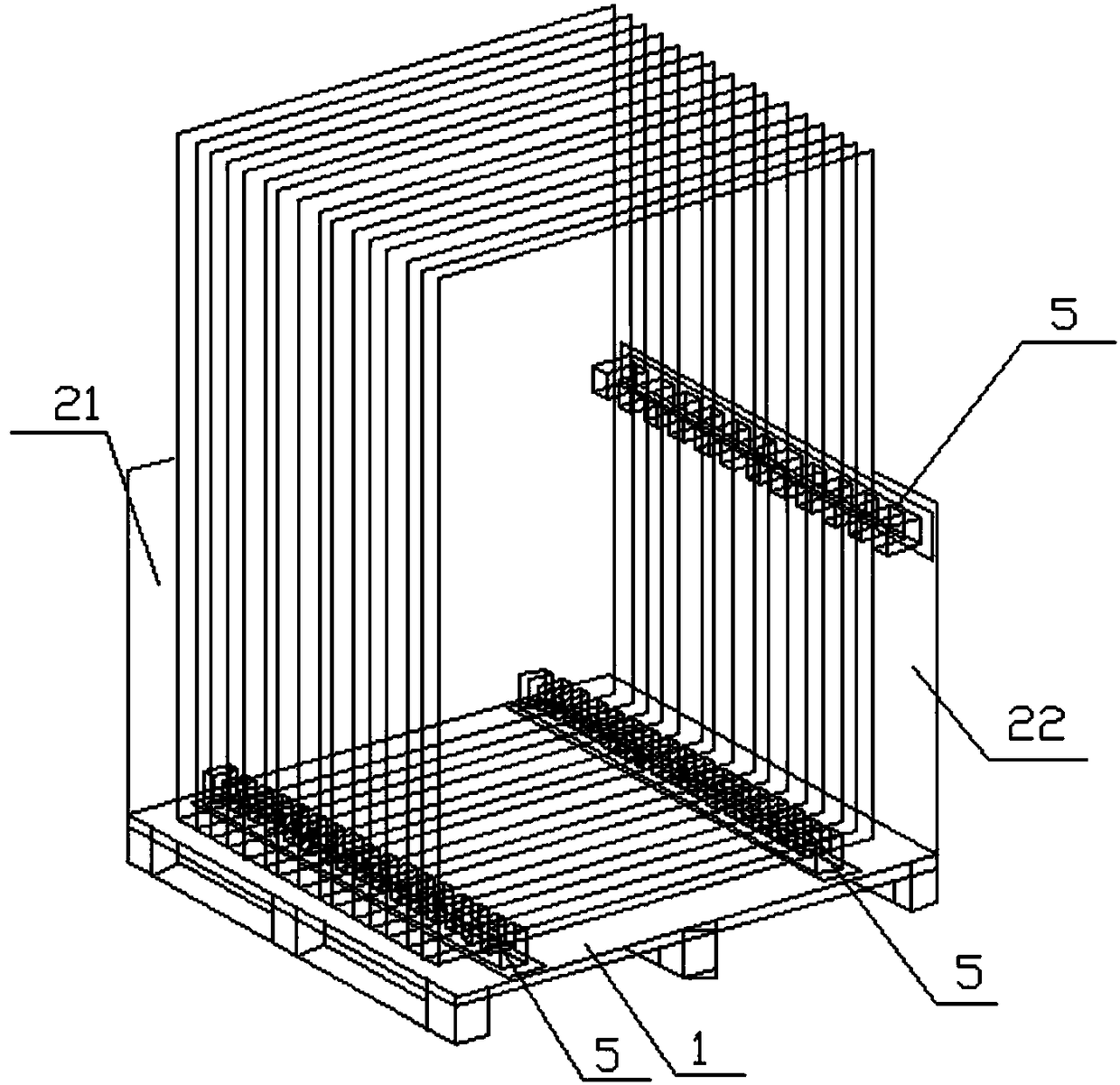

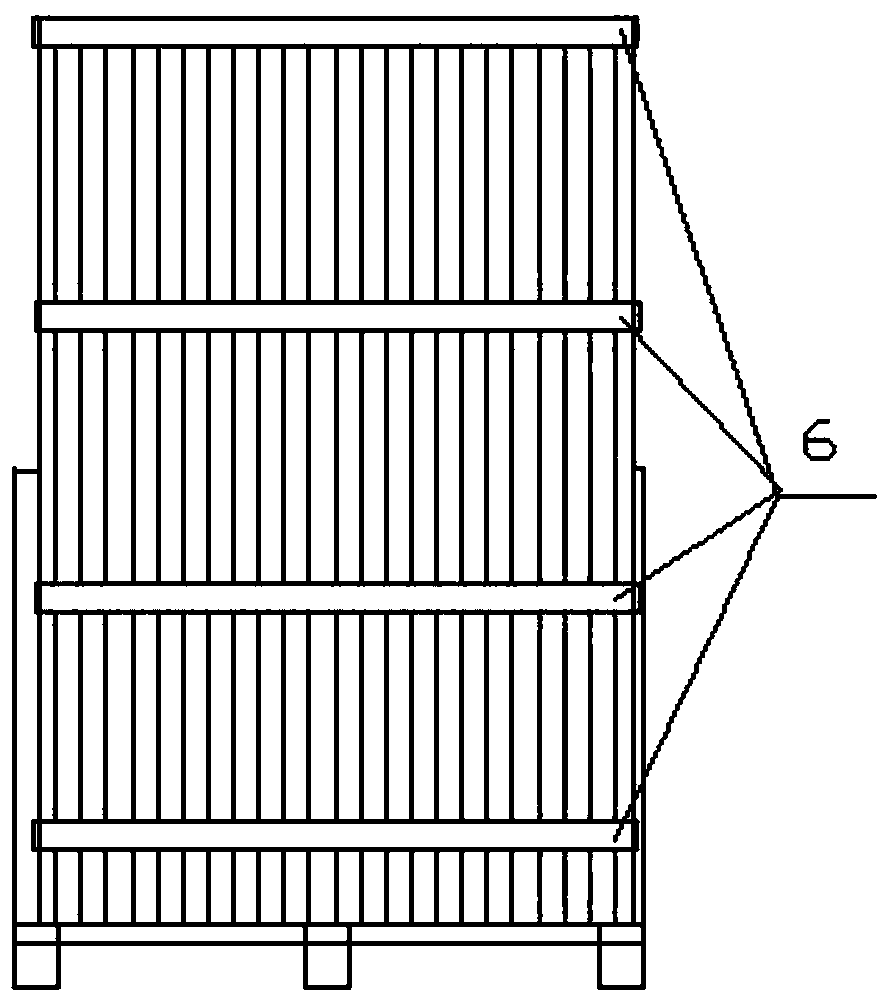

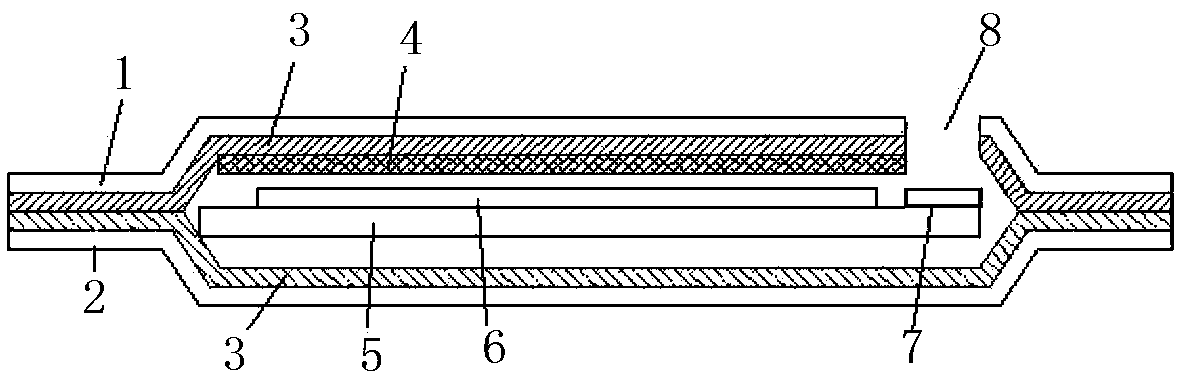

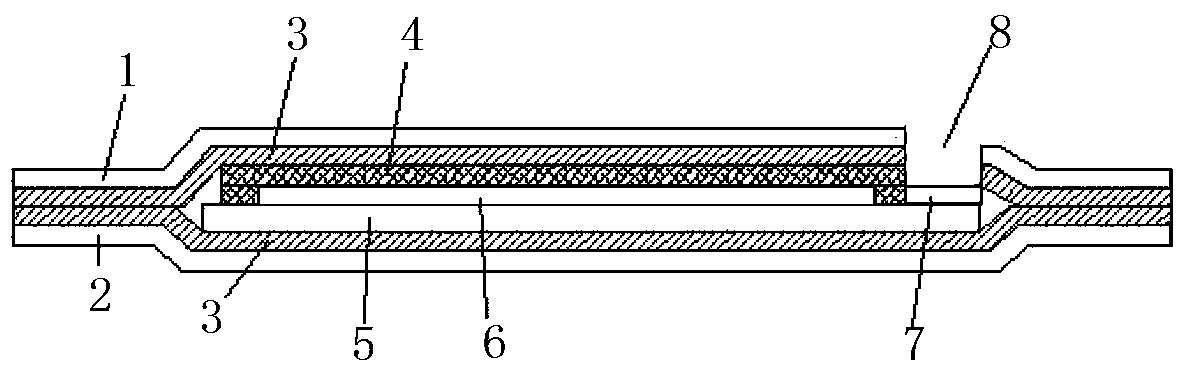

Base plate packaging method

InactiveCN104037363AThe packaging method is simpleEasy to operateSolid-state devicesSemiconductor/solid-state device manufacturingBiochemical engineeringLight-emitting diode

The invention provides a base plate packaging method which includes the following steps: 1 providing a base plate (1) and a packaging plate (3); 2 arranging a ring of inorganic insulation film (5) is arranged on the packaging plate (3); 3 arranging a ring of ultraviolet glue (7) on the outside of the inorganic insulation film (5) on the packaging plate (3); 4 bonding the packaging plate (3) and the base plate (1) relatively; 5 utilizing a UV light source to irradiate the UV glue (7) to enable the UV glue to be solidified to achieve package of the base plate (1) by the packaging plate (3). By means of the packaging method, the packaging effect is improved, the steam and oxygen blocking capability is improved, the service life of an organic light emitting diode (OLED) device is prolonged, and the method is simple, feasible and good in operability.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

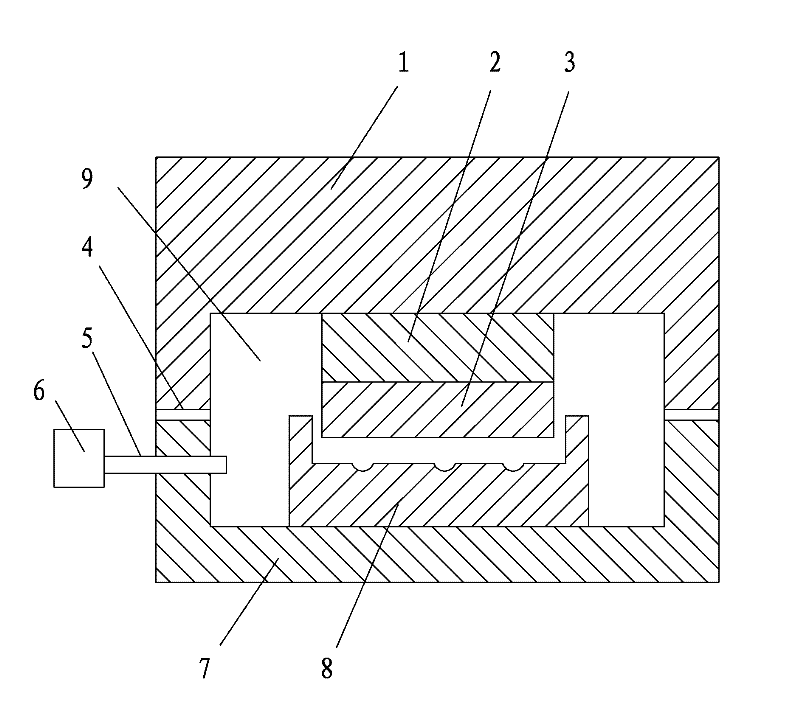

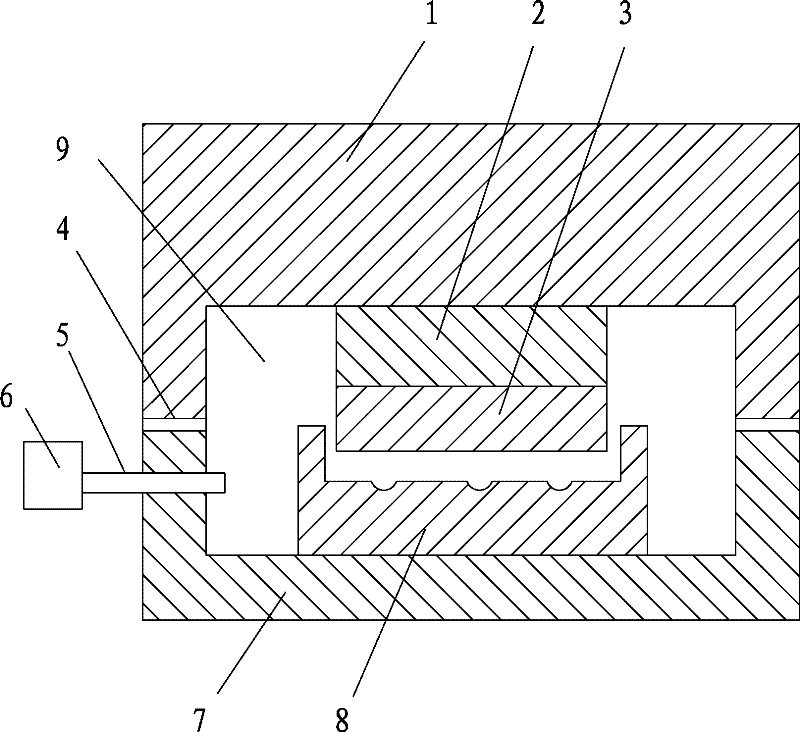

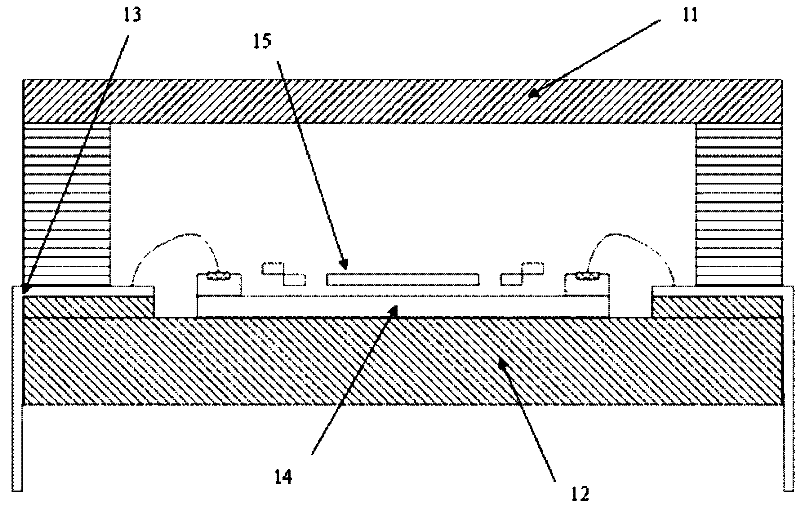

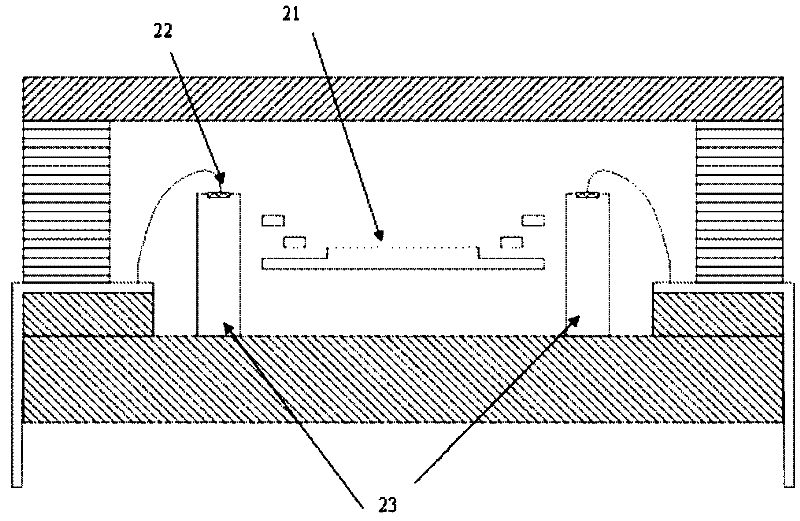

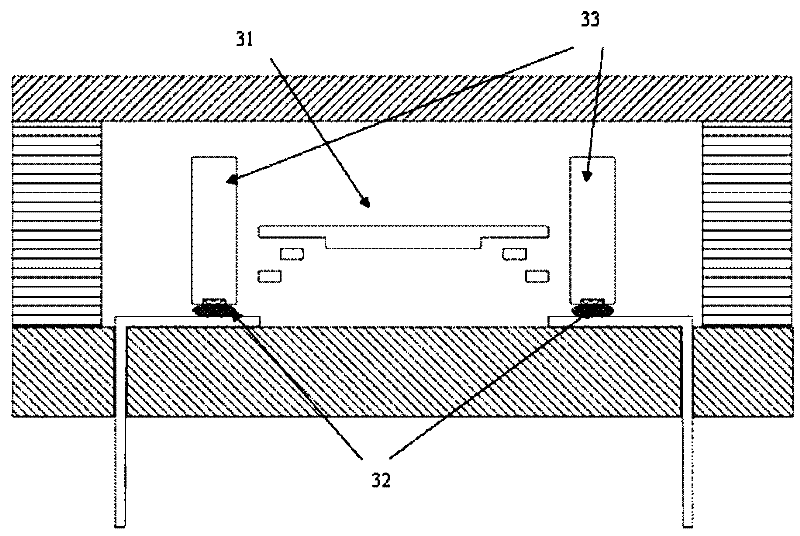

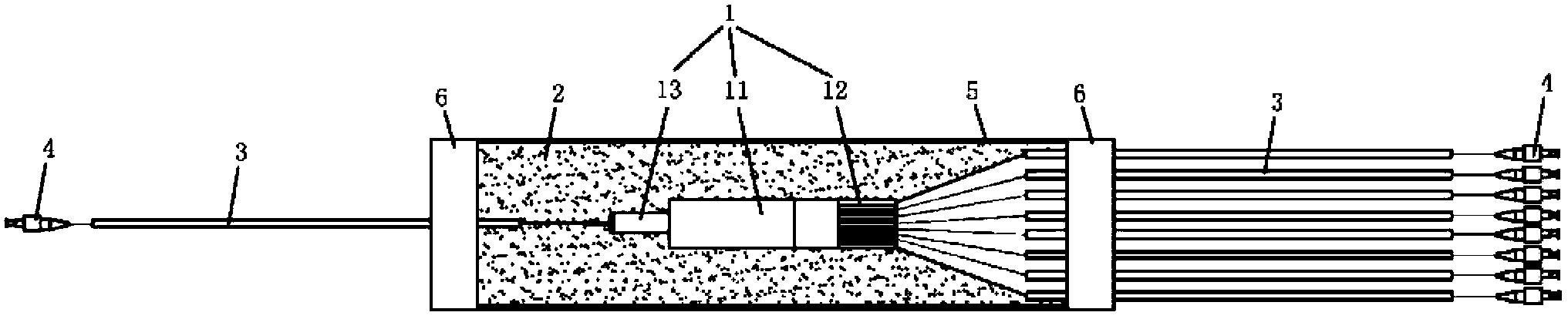

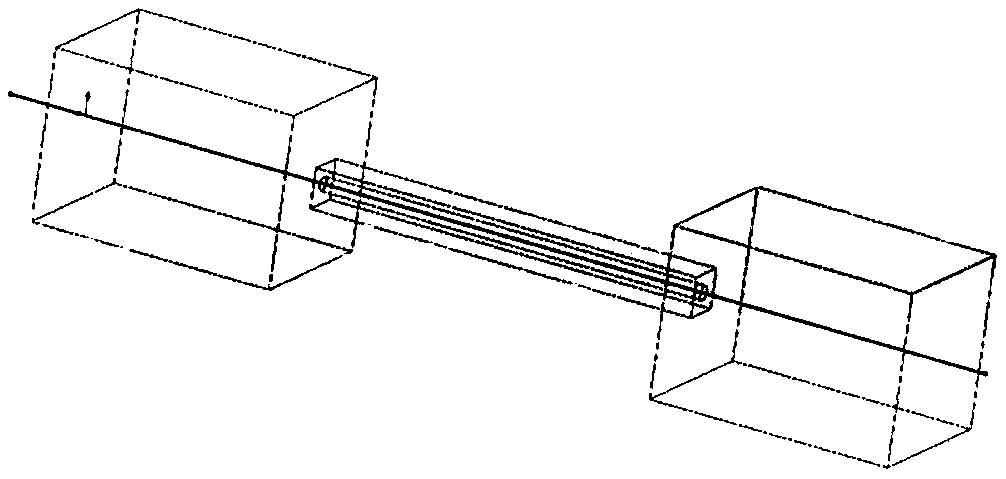

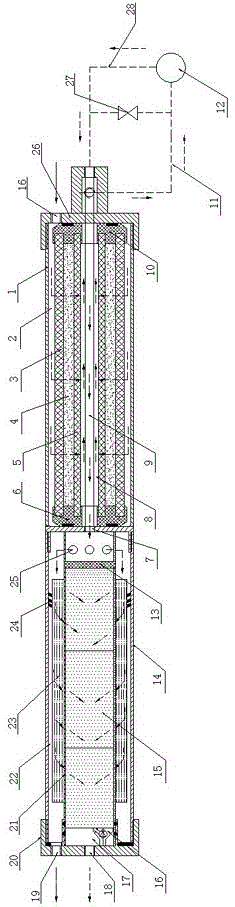

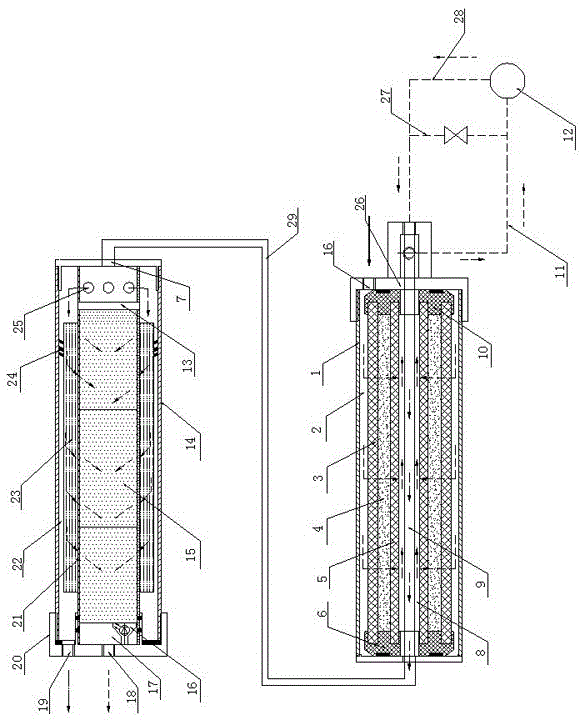

A kind of led vacuum encapsulation device and vacuum encapsulation method

The invention relates to an LED (Light-Emitting Diode) encapsulating technology. An LED vacuum encapsulating device comprises a substrate and a forming die, wherein the substrate is arranged above the forming die, the substrate is matched with the forming die; and the vacuum encapsulating device is also provided with an upper die and a lower die which are mutually matched to form a sealed die cavity, the substrate and the forming die are arranged in the die cavity, and the die cavity is communicated with a vacuum air extractor. The LED vacuum encapsulating method comprises the following stepsof: injecting glue, namely injecting the required encapsulating glue into the forming die; closing the dies comprising the upper die and the lower die, vacuumizing the die cavity by virtue of a vacuum tube, and pressing the injected encapsulating glue by the substrate; extruding the encapsulating glue by the substrate, thus the encapsulating glue flows into a die hole of the forming die; and after the encapsulating glue is hardened, opening the upper die, thus LED encapsulating and forming are completed. In a pressing process of the substrate and the forming die, the die cavity is in a vacuumenvironment, the substrate presses silica gel without generating bubbles, thus the LED vacuum encapsulating device has high yield and good encapsulating effect.

Owner:东莞市福地电子材料有限公司

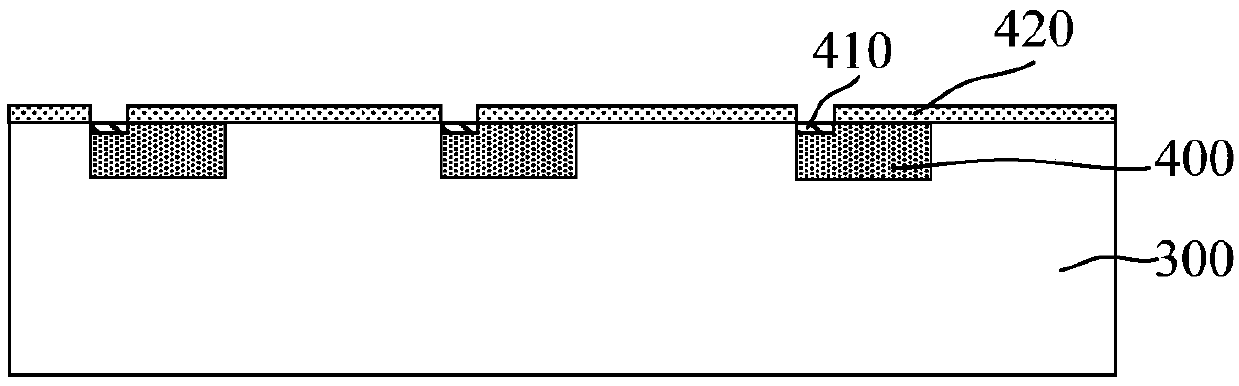

Wafer level packaging method and packaging structure

ActiveCN110875203AAchieve electrical connectionThe packaging method is simpleSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionDielectric layer

The invention provides a wafer level packaging method and a packaging structure. The method comprises the steps: a first wafer is provided, wherein a plurality of first chips are formed in the first wafer, the surface of the first chip is provided with a first electrode, and a first dielectric layer exposing the first electrode is formed on the surface of the first wafer; a plurality of second chips are provided, wherein the surface of the second chip is provided with a second electrode, and a second dielectric layer exposing the second electrode is formed on the second chip; the second dielectric layer and the first dielectric layer are oppositely arranged so that the second chip is enabled to be bonded to the first wafer, wherein the position of the second chip is enabled to correspond to the position of the first chip, and a cavity is formed between the first electrode and the second electrode; a chip interconnection structure for electrically connecting the first electrode and thesecond electrode is formed in the cavity; and a packaging layer covering the second chip is formed. Thus, the packaging process is simplified.

Owner:NINGBO SEMICON INT CORP

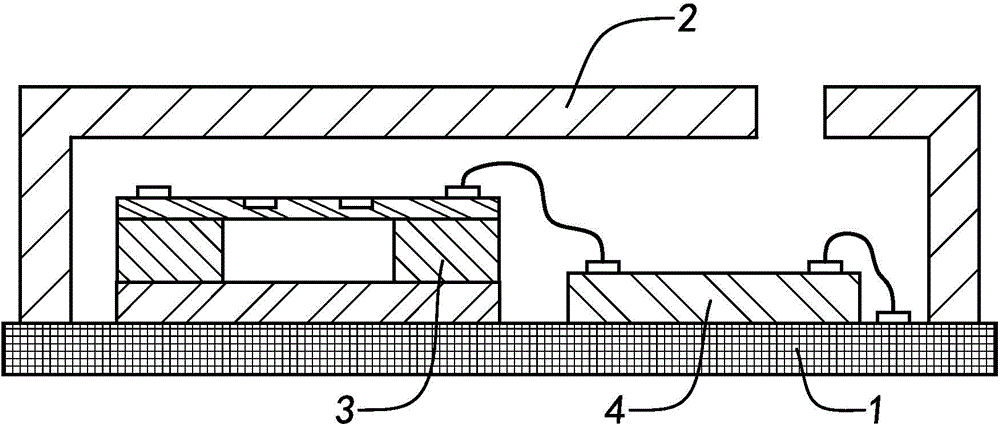

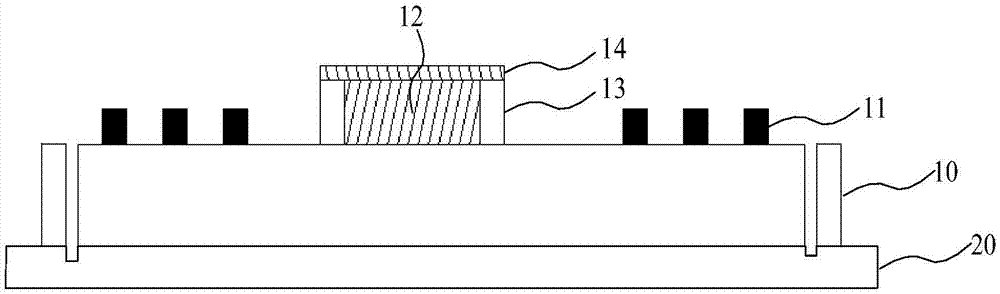

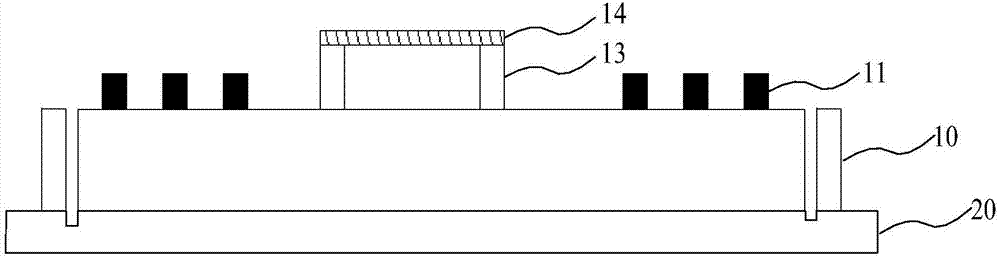

MEMS pressure sensor device and packaging method thereof

ActiveCN104865002ARealize Back Sensing PressureChange contact positionDecorative surface effectsFluid pressure measurement using ohmic-resistance variationMems pressure sensorEngineering

The invention provides an MEMS pressure sensor device and a packaging method thereof. The MEMS pressure sensor device comprises the components of an integrated circuit, an MEMS pressure sensor which is connected with the integrated circuit, and a packaging assembly. The packaging assembly comprises a substrate and a cover plate. The cover plate is connected with the substrate and an accommodating space is formed, wherein the MEMS pressure sensor and the integrated circuit are connected with the substrate and are arranged in the accommodating space. The substrate is provided with a ventilation hole. Outside atmosphere contacts with the MEMS pressure sensor through the ventilation hole, so that the MEMS pressure sensor is suitable for sensing the outside air pressure through the back part of the MEMS pressure sensor.

Owner:苏州曼普拉斯传感科技有限公司

Packaging method of fan-out type chip, and packaging structure

InactiveCN105489516AImprove performanceImprove yieldSemiconductor/solid-state device detailsSolid-state devicesBiomedical engineeringPlastic packaging

The invention provides a packaging method of a fan-out type chip, and a packaging structure. The packaging structure comprises chips with projections, wherein a dielectric layer is formed on the surfaces of the chips, and the projections are exposed from the surfaces; a plastic packaging material filled among the chips with the projections, wherein the height of the plastic packaging material is not higher than that of each projection so as to enable the projections to be exposed from the surface of the plastic packaging material; a rewiring layer formed on the chips with the projections and realizing interconnection among the chips; and projection lower metal layers and dimpling points. According to the invention, the dielectric layer exposing the projections is formed on the surfaces of the chips with the projections, the projections are protected, the subsequent interconnection among the chips is realized, and damaged or broken conditions of the projections caused by thermal expansion in the subsequent processes for manufacturing the rewiring layer of solder dimpling points are avoided, so that the packaging performance is substantially improved, and the yield is simultaneously improved.

Owner:SJ SEMICON JIANGYIN CORP

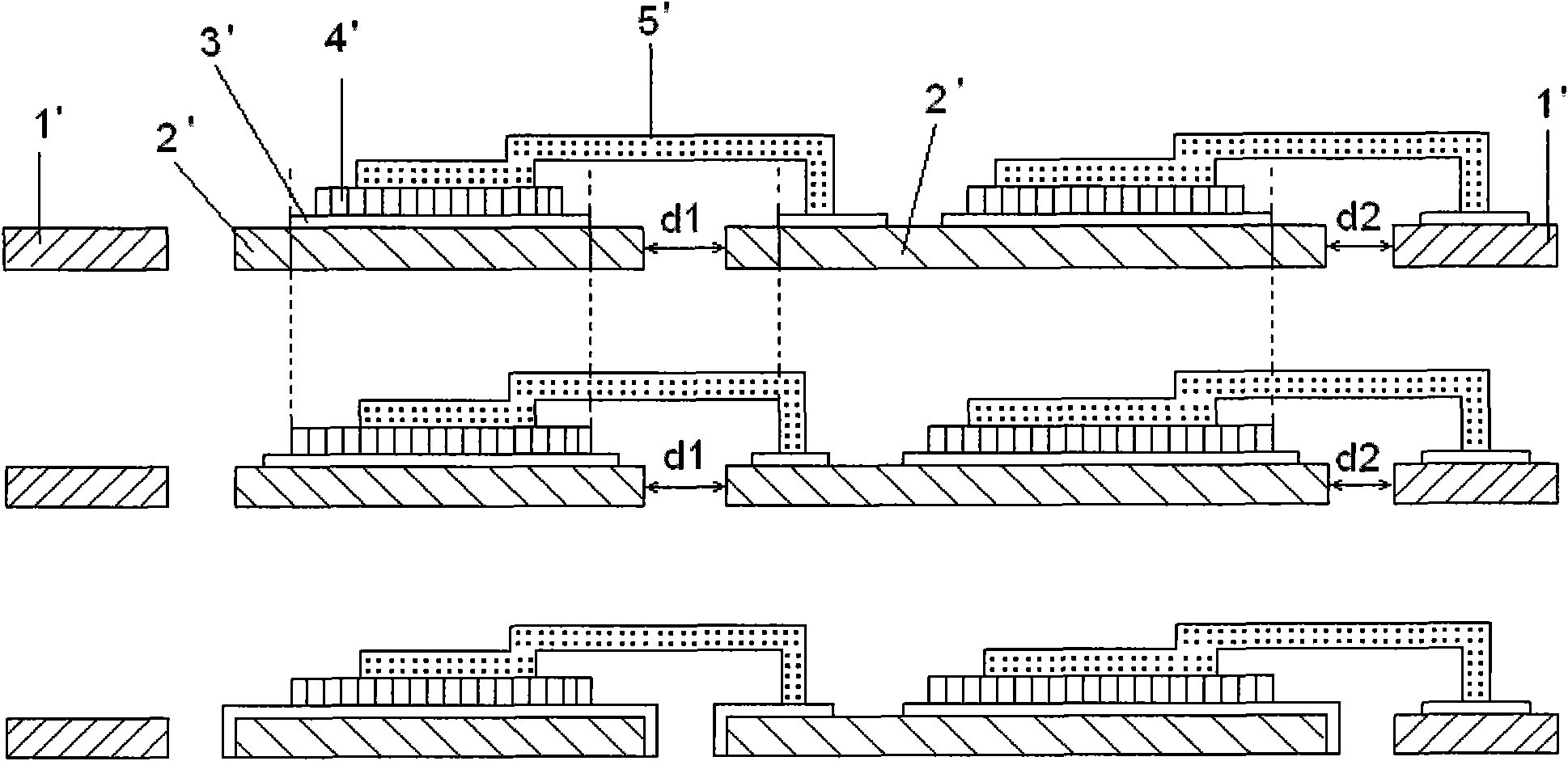

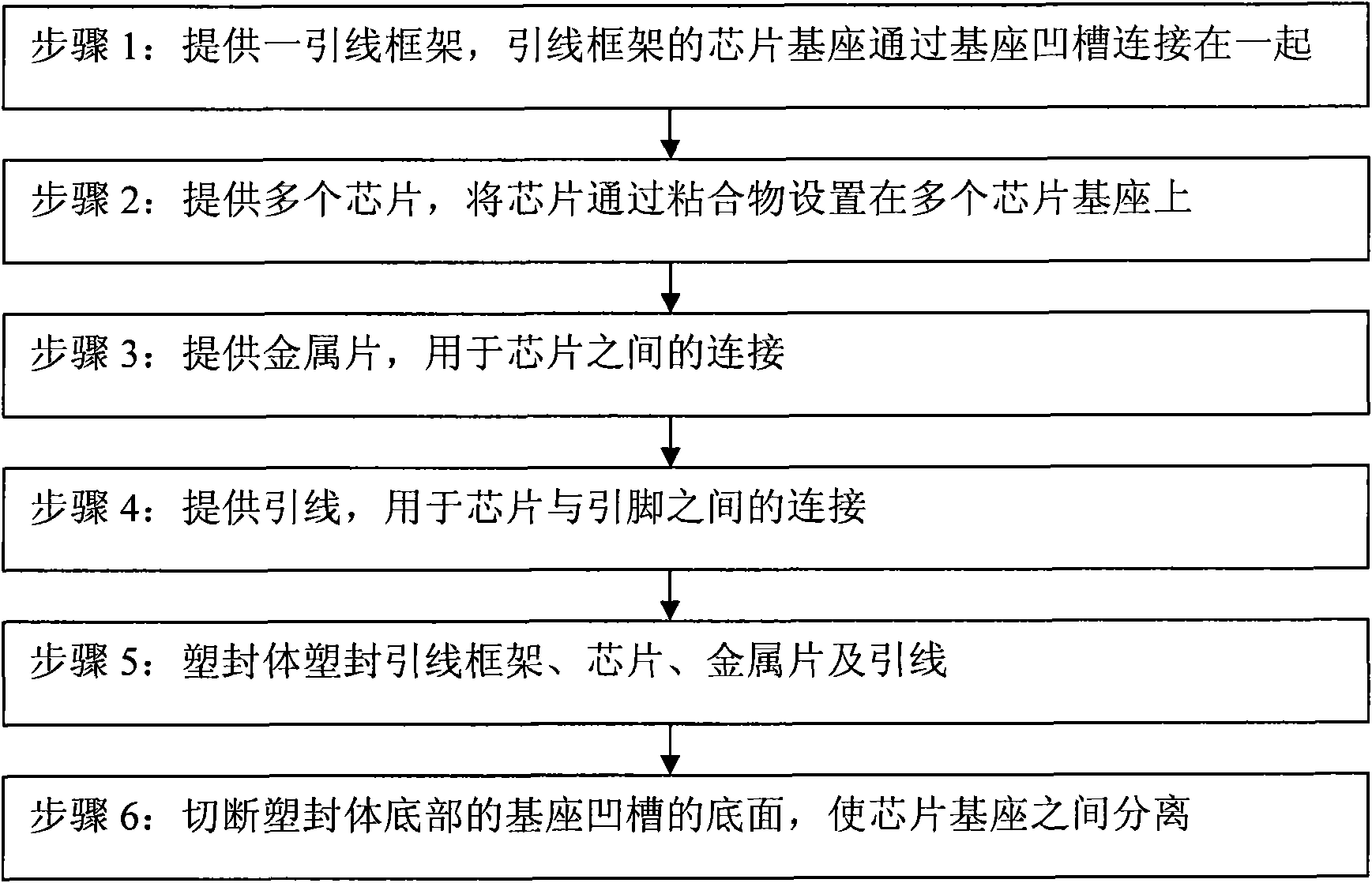

Semiconductor packaging through metallic bonding and method for same

ActiveCN102403295AAvoid pollutionPrevent overflowSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageMetallic bonding

The invention discloses a method for semiconductor packaging through metallic bonding, which is characterized in that the method includes the steps of firstly, providing a lead frame which comprises a chip substrate and pins, wherein the upper surface of the chip substrate is provided with at least one substrate groove which divides the whole chip substrate into a plurality of chip mounting areas, secondly, providing a plurality of chips which are all mounted in the corresponding chip mounting areas of the chip substrate through bonding, thirdly, providing at least one metallic sheet for connecting the chips, fourthly, providing leads for connecting the chips with the pins, fifthly, providing a plastic package body for packaging the structure, and sixthly, cutting off bottoms of the substrate grooves after packaging, so that the chip mounting areas in mutual connection are divided into disconnected chip mounting areas. The packaging method is capable of effectively preventing contamination caused by bonding overflowing during mounting of the chips to chip mounting equipment, the utilization ratio of the chips inside the package body is increased, and packaging cost is reduced.

Owner:ALPHA & OMEGA SEMICON LTD

Method for constructing artificial multi-enzyme system based on lanthanide series nucleotide compound and DNA (Deoxyribonucleic Acid) oriented immobilization technology

ActiveCN109810969AGood biocompatibilityHigh activityOxidoreductasesOn/in inorganic carrierNucleotideAdenosine

The invention provides a method for constructing an artificial multi-enzyme system based on a lanthanide series nucleotide compound and a DNA (Deoxyribonucleic Acid) oriented immobilization technologyand belongs to the field of preparation of immobilized enzymes. The method comprises the following steps: firstly, preparing single-stranded DNA modified magnetic nanoparticles and complementary single-stranded DNA functionalized glucose oxidase; then mixing the magnetic nanoparticles with the enzyme; carrying out DNA complementary hybridization to realize the immobilization of the enzyme; commonly hatching the immobilized enzyme, cerium nitrate hexahydrate and disodium adenosine 5'-phosphate; carrying out self-assembling on a lanthanide series nucleotide coordinated polymer to realize the encapsulation of the immobilized enzyme and constructing the artificial multi-enzyme system. An encapsulation vector can realize the effect of protecting the immobilized enzyme and is also used as an analogue enzyme to form an enzyme cascade system with the immobilized natural enzyme. A preparation process of the artificial multi-enzyme system, provided by the invention, is simple, has moderate conditions and achieves high enzyme activity; the artificial multi-enzyme system is easy to separate from a reaction system and has excellent stability and reusability; meanwhile, the analogue enzyme is introduced and the cost is extremely reduced.

Owner:BEIJING UNIV OF CHEM TECH

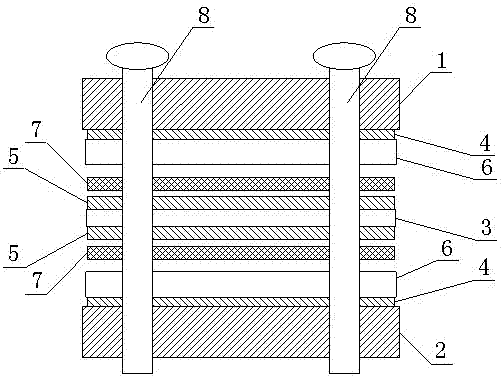

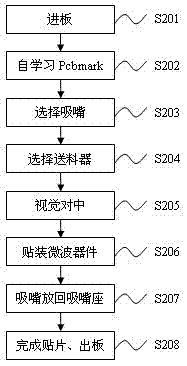

Surface mount microwave device and packaging process thereof

ActiveCN103050453AReduce volumeImprove the effective dielectric constantPrinted circuit assemblingSemiconductor/solid-state device detailsDielectricElectricity

The invention discloses a surface mount microwave device. Copper foil layers (4) and copper foil circuit layers (5) are symmetrically arranged between cover plates and a central medium material layer (3). Medium material layers (6) are arranged between the copper foil layers (4) and the copper foil circuit layers (5). Press-fitting glue film layers (7) for press-fitting are arranged between the copper foil circuit layers (5) and the medium material layers (6). A packaging process comprises the following steps of: tin paste printing, automatic mounting, curing, reflow soldering and cleaning to complete packaging. Since a strip line structure is used instead of a microstrip line and a copper foil circuit line in the strip line is in a folded and multilayer structure, the effective dielectric constant of the circuit is improved and the size of the microwave device is greatly reduced; and since a surface mount packaging method is adopted, slots for installation are not needed to be excavated in a printed circuit board and a chamber body, the printed circuit board is directly installed, the surface mounting is realized, the design and the realization of a microstrip circuit and a microstrip system are facilitated and optimized, the applicability is greatly increased and the application scope is wider.

Owner:成都泰格微电子研究所有限责任公司

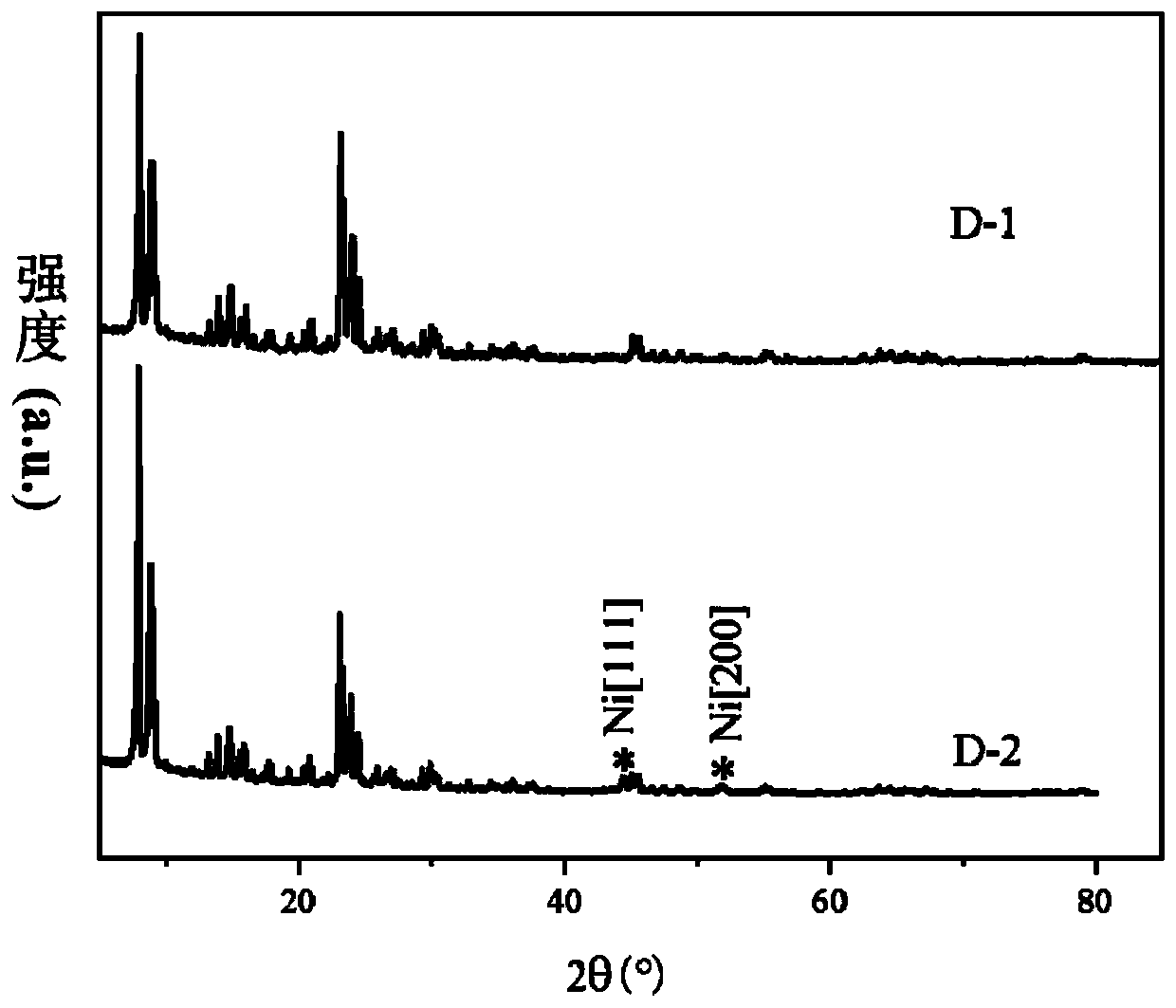

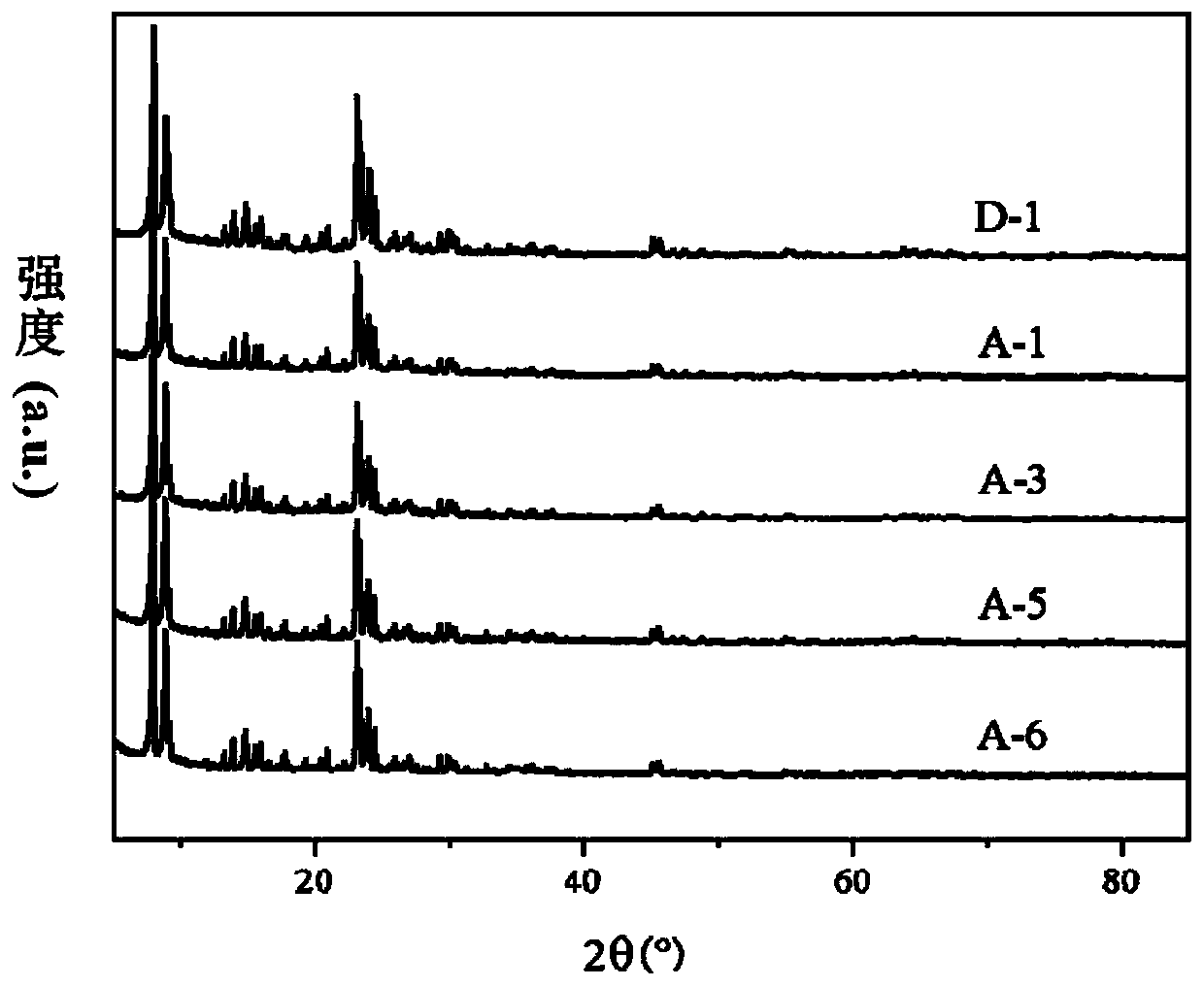

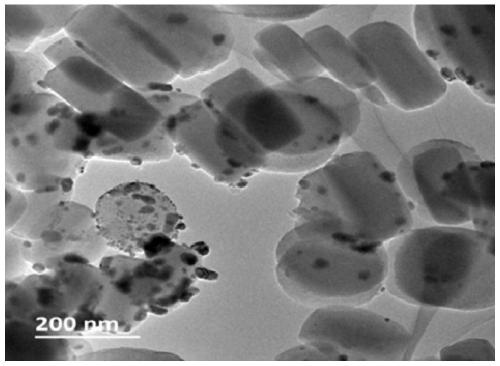

Packaging method of Ni@ZSM-5 bifunctional catalyst

ActiveCN111250152AEvenly distributedUniform particle sizeMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

The invention relates to a packaging method of an Ni@ZSM-5 bifunctional catalyst. The packaging method comprises the following step: with an FAU structure molecular sieve as an aluminum source and a metal Ni precursor as a Ni source, packaging metal nickel in the preparation process of a ZSM-5 molecular sieve through crystal transformation so as to obtain the Ni@ZSM-5 bifunctional catalyst. The Ni@ZSM-5 packaged catalyst obtained by using the packaging method has the double functions of metal hydrogenation and molecular sieve acid catalysis, so the application range of the packaged catalyst isremarkably widened; the packaged metal Ni nanoparticles are uniform in distribution and uniform in particle size; and in addition, the Ni@ZSM-5 bifunctional catalyst is packaged in a sodium-free system, a subsequent ion exchange step does not exist, and the packaging method is rapid, simple and convenient in process, short in flow, low in cost and easy for industrial operation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Microelectromechanical system micromirror package

ActiveCN102298207AAdd anti-reflection filmThe packaging method is simpleSolid-state devicesSemiconductor devicesAnti jammingMicroelectromechanical systems

The invention discloses a packaging structure of a micromirror with a micro electro mechanical system, which is used for carrying out wafer level lamination seal packaging on a micromirror with the micro electro mechanical system by utilizing the self peripheral frame of system micromirror with the micro electro mechanical system, which is characterized by comprising a top layer transparent cover plate, a middle layer micro electro mechanical system micromirror and a bottom layer substrate, wherein the micro electro mechanical system micromirror comprises a micromirror body and a micromirror surrounding silicon frame; the lower surface of the top layer transparent cover plate and the micromirror surrounding silicon frame form a cavity body capable of accommodating the micromirror body to move; the bottom layer substrate is used for supporting the micromirror with the micro electro mechanical system, and the micromirror with the micro electro mechanical system, the top layer transparent cover plate, the micromirror surrounding silicon frame and the bottom layer substrate form a closed cavity body; and the micromirror body is arranged in the closed cavity body. The packaging structure is the smallest packaging structure of the micromirror with the micro electro mechanical system, and has high production efficiency and lower cost. By adopting the packaging structure, the micromirror has strong anti-jamming capability and long service life.

Owner:无锡微文半导体科技有限公司

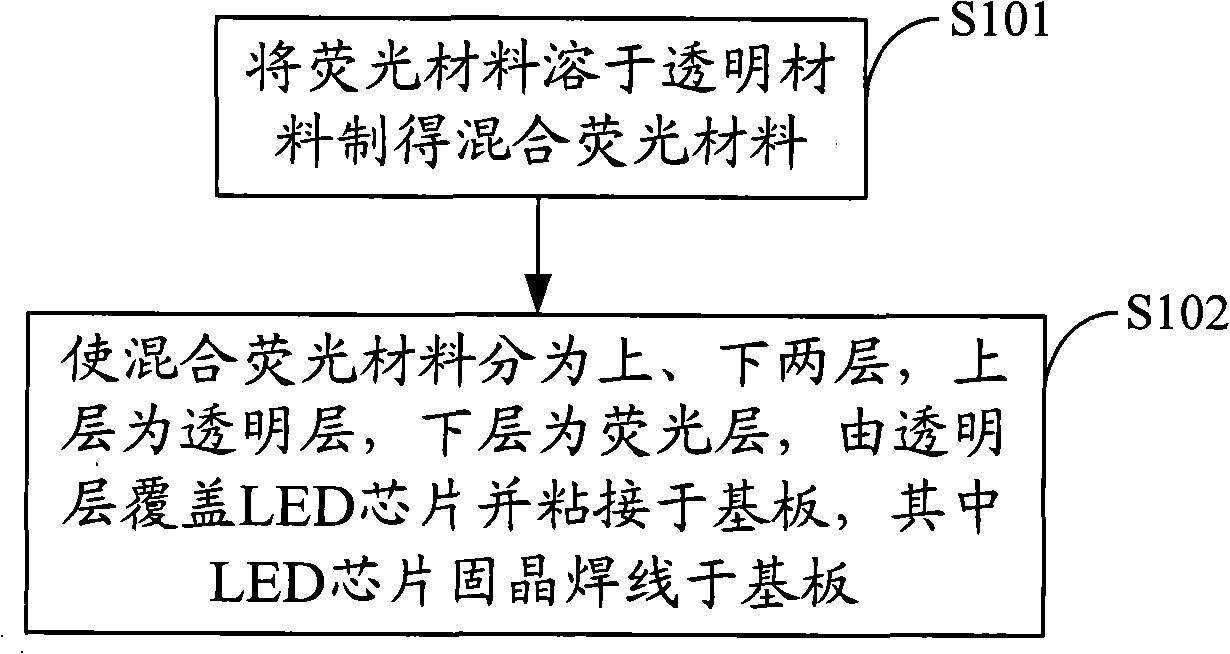

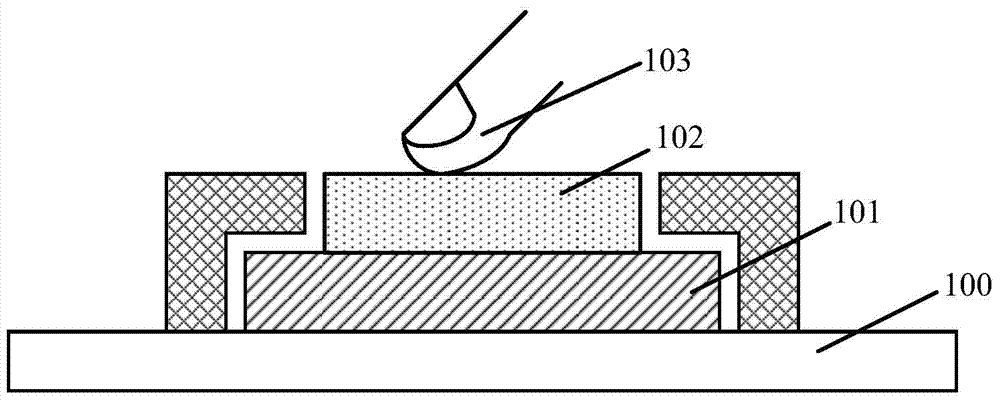

Method for encapsulating light-emitting diode (LED), LED and LED illumination device

InactiveCN101980385AImprove light extraction efficiencyThe packaging method is simplePoint-like light sourceElectric lightingEngineeringWire bonding

The invention is suitable for the field of illumination, and provides a method for encapsulating a light-emitting diode (LED), an LED and an LED illumination device. The method for encapsulating the LED comprises the following steps of: dissolving a fluorescent material into a transparent material to prepare a mixed fluorescent material; and dividing the mixed fluorescent material into an upper layer serving as a transparent layer and a lower layer serving as a fluorescent layer, and covering an LED chip through the transparent layer and bonding the LED chip to a substrate, wherein the LED chip is subjected to die bonding and wire bonding on the substrate. In the method, the fluorescent material is dissolved into the transparent material to prepare the mixed fluorescent material, the mixed fluorescent material is divided into the upper layer serving as the transparent layer and the lower layer serving as the fluorescent layer, and the LED chip is covered by the transparent layer and is bonded to the substrate; and the fluorescent layer is far away from the LED chip, and an interface is not reserved between the fluorescent layer and the transparent layer, so that the light-emitting efficiency of the LED is improved greatly, and the encapsulating method is simple and easy to control, has a small number of steps and can realize high-efficiency encapsulation.

Owner:宁波市瑞康光电有限公司

Silicon-based photonic integrated structure and preparation method

ActiveCN108267820ALow costThe packaging method is simpleCoupling light guidesPhotonicsMiniaturization

The present invention belongs to the semiconductor optoelectronic technological field and relates to a silicon-based photonic integrated structure and a preparation method. The integrated structure comprises a laser driving circuit, at least one laser, monitoring detectors, an optical waveguide, and a silicon-based substrate, wherein the number of the at least one laser is corresponding to the number of the monitoring detectors; the laser driving circuit is electrically connected with the lasers; the lasers, the monitoring detectors, and the optical waveguides are optically connected with oneanother; and the laser driving circuit, the lasers, the monitoring detectors, and the optical waveguide are all disposed on the same silicon-based substrate. According to the silicon-based photonic integrated structure of the invention, the laser driving circuit, a multi-wavelength chip and a multi-optical path composite chip are integrated on the same substrate, and therefore, the silicon-based photonic integrated structure has the advantages of high integration, high performance, low cost and easiness in packaging. With the silicon-based photonic integrated structure adopted, the further development of a communication module in the corresponding industry in high integration and miniaturization can be benefitted.

Owner:WUHAN TELECOMM DEVICES

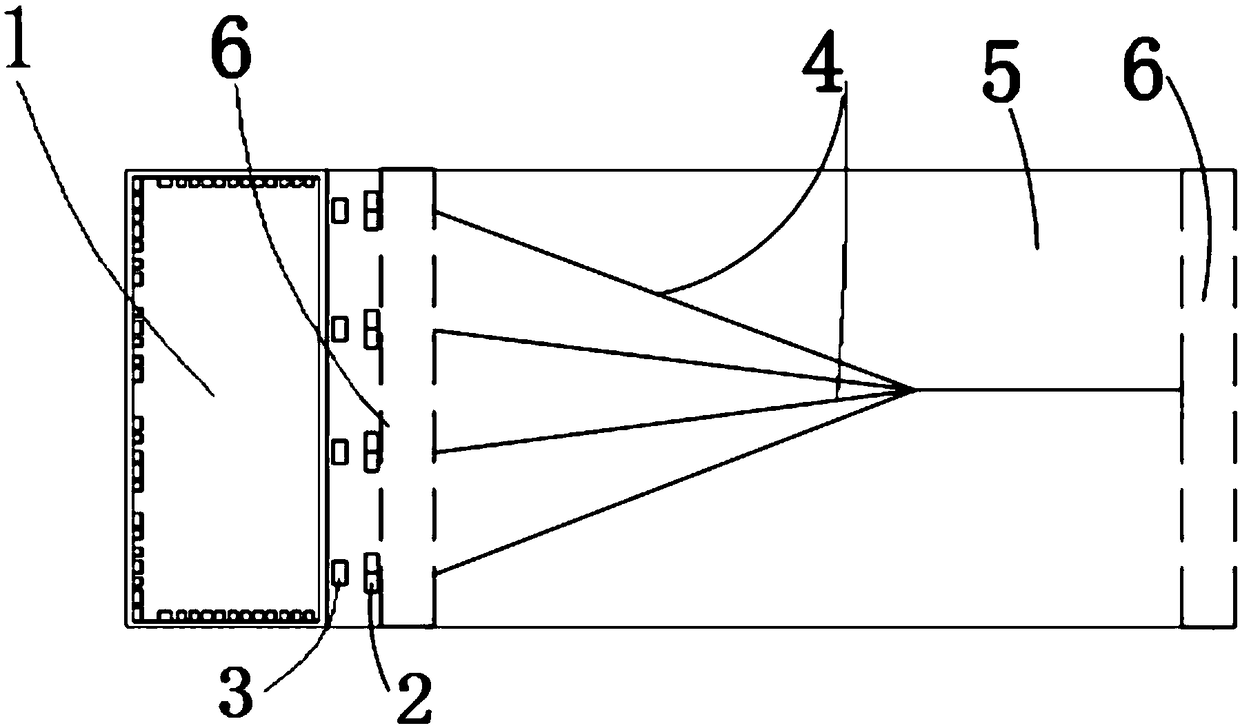

Planar optical waveguide branching unit and encapsulating method thereof

InactiveCN103257418ANo drippingSimple structureFibre mechanical structuresHigh humidityHigh pressure

The invention discloses a planar optical waveguide branching unit and an encapsulating method thereof and belongs to an optical communication matching device. The planar optical waveguide branching unit comprises a branching device body, the branching device body is arranged in an encapsulating body, optical factice is filled in the encapsulating body, and the branching device body is submerged in the optical factice. Due to the characteristics that the optical factice is not melted in a high temperature range, has no phase-change or structure change, keeps softness in low temperature, has no dripping phenomenon when temperature is increased and the like, after the optical factice is filled between the branching device body and the inner wall of the encapsulating body, the planar optical waveguide branching unit can be used in all kinds of hostile environments, and technical requirements for high-temperature, high-humidity and high-pressure experiments in telecommunication industry are met. Meanwhile, the planar optical waveguide branching unit is simple in structure, capable of being applied to all types of planar optical waveguide branching units, wide in range of application, simple in encapsulating method, suitable for industrial production and easy to popularize.

Owner:四川思迈科技有限公司

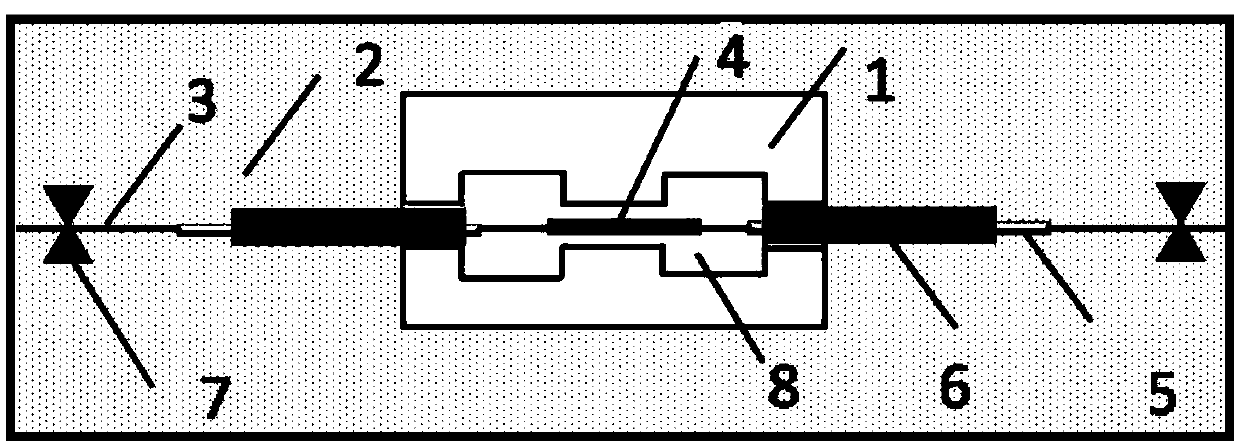

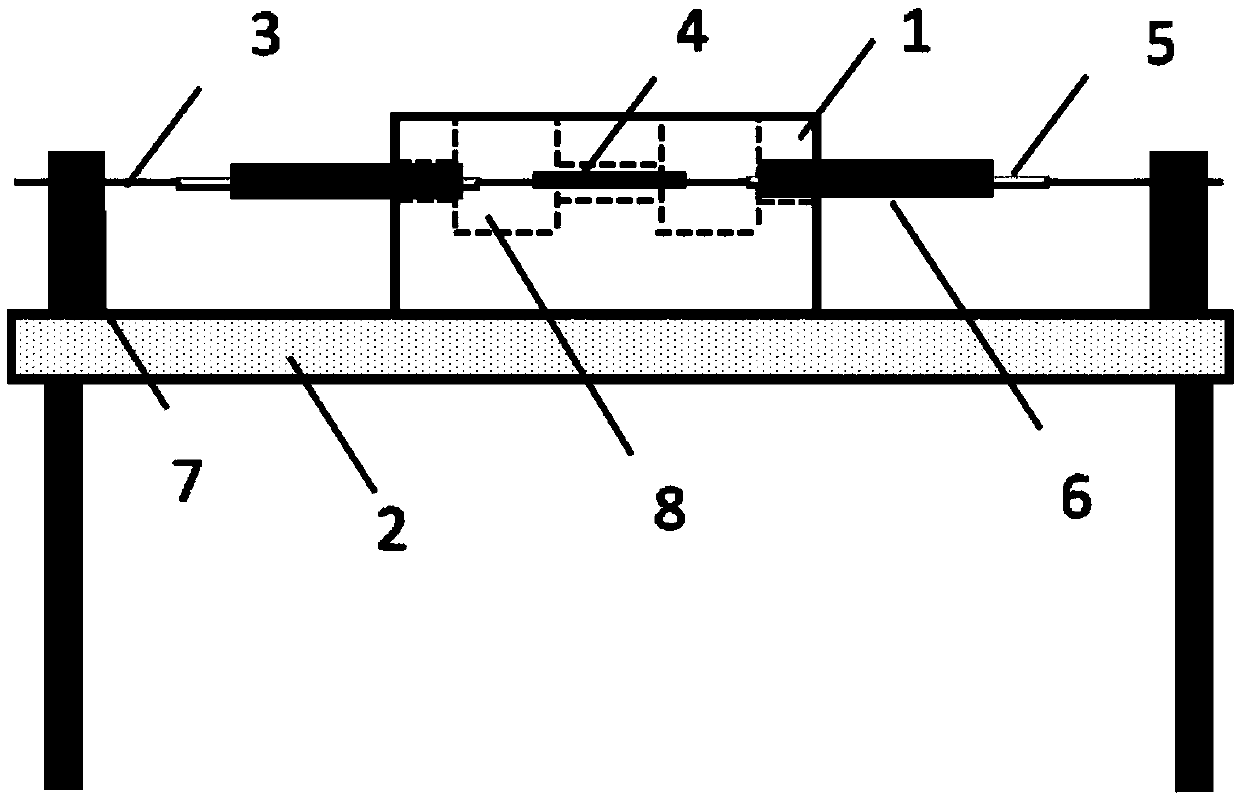

Method for preparing sensor by using polyurethane package fiber grating

InactiveCN108680289AWith wear resistanceWide range of hardnessForce measurement by measuring optical property variationPolyurethane elastomerFiber

The invention provides a method for preparing a sensor by using a polyurethane package fiber grating and belongs to the technical field of optical fiber communication and light sensing. According to the method, polyurethane is used as a packaging material. The method comprises a step of fixing a package mold on a fiber platform, peeling a coating of a grating region and allowing the grating regionto enter a capillary steel pipe, fixing a bare fiber on the fiber platform with a clamp to ensure that the fiber is placed at an axis center of the mold, a step of sleeving two ends of the bare fiberwith protective sleeves in order, and a step of pouring the polyurethane into the mold which is coated with a release agent in advance, placing the mold into a vacuum box to be dried and solidified.The fiber grating and a fiber core with the removal of a coating are packaged with polyurethane elastomers to avoid the incompatibility of different materials. The package method of the invention is simple, reliable and portable, the prepared sensor can be monitored by changing the stress, temperature and the like of equipment, the method can be suitable for various industrial applications, and the stability, reliability and sensitivity of the packaged fiber grating are significantly improved.

Owner:DALIAN UNIV OF TECH

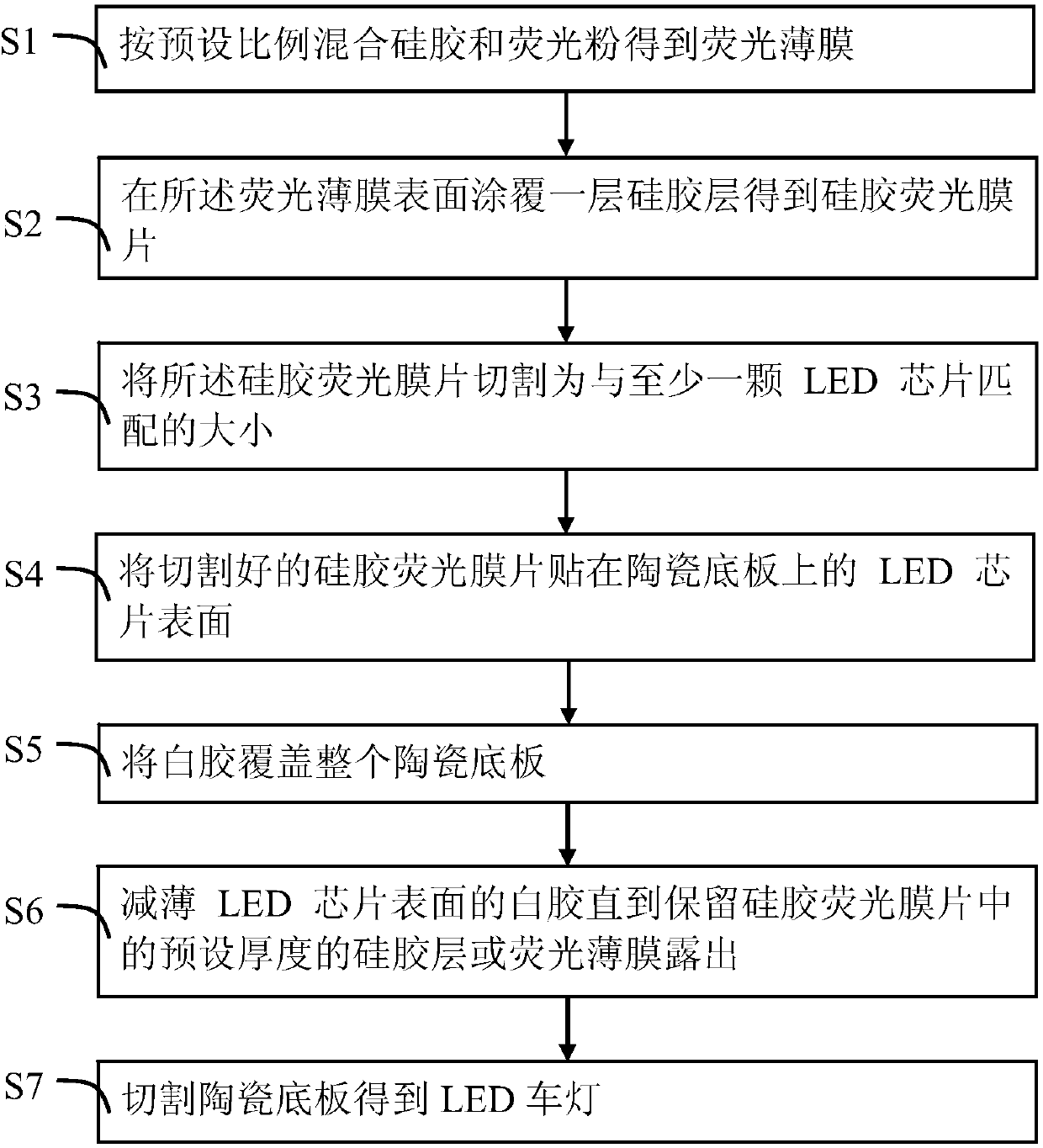

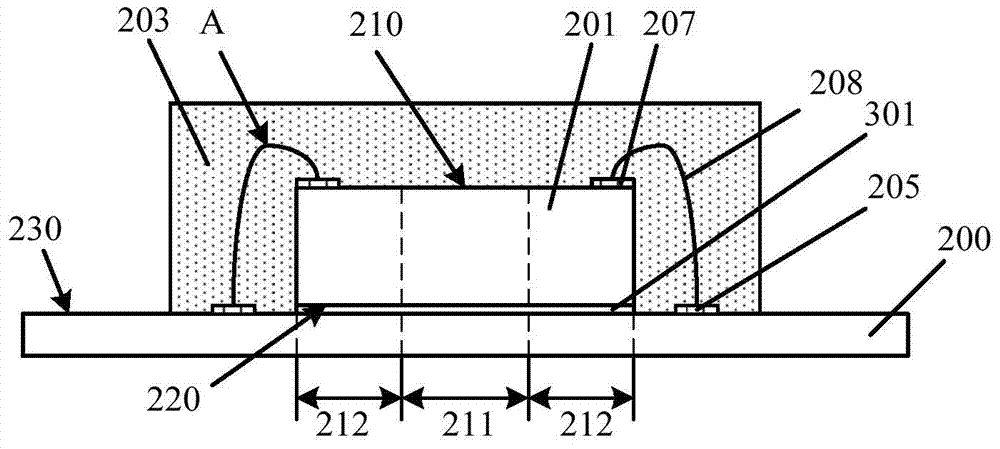

LED automobile lamp packaging method

ActiveCN107681041AThe packaging method is simpleSmooth appearanceSemiconductor devicesFluorescenceEngineering

The invention provides an LED automobile lamp packaging method. The LED automobile lamp packaging method includes the steps of: S1. mixing silica gel and fluorescent powder according to a preset proportion to obtain a fluorescent film; S2. coating the surface of the fluorescent film with a silica gel layer to obtain a silica gel fluorescent diaphragm; S3. cutting the silica gel fluorescent diaphragm into a size matched with at least one LED chip; S4. pasting the cut silica gel fluorescent diaphragm on the surface of the LED chip on a ceramic bottom plate; S5. covering the whole ceramic bottomplate with white glue; S6. thinning the white glue on the surface of the LED chip till the silica gel layer of a preset thickness in the silica gel fluorescent diaphragm is kept or the fluorescent film is exposed; and S7. cutting the ceramic bottom plate to obtain an LED automobile lamp. The LED automobile lamp packaging method provided by the invention is simple and practicable, and does not needto be additionally equipped with special equipment, thereby saving cost.

Owner:JIANGXI LATTICEBRIGHT

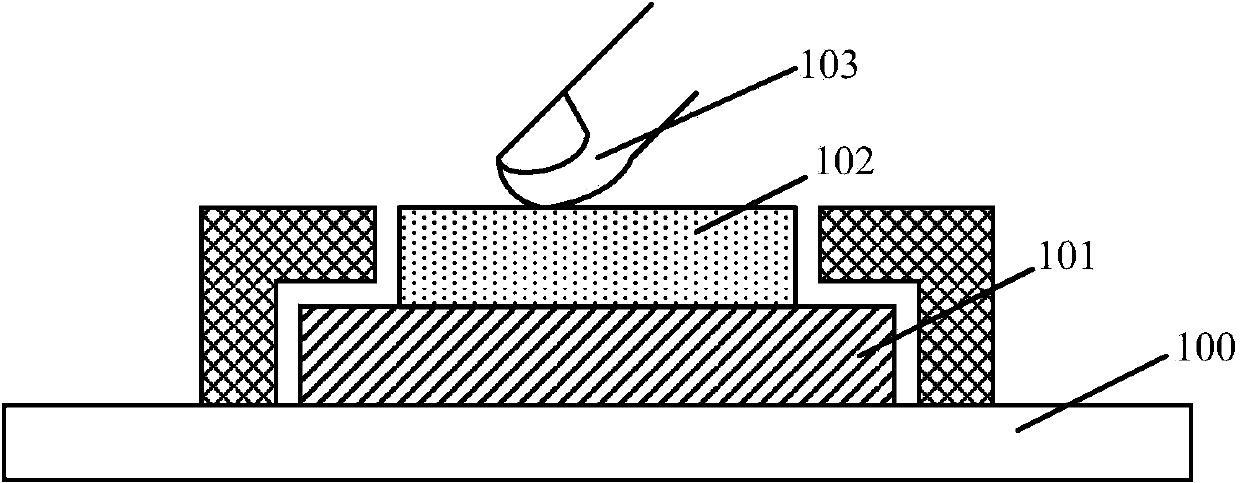

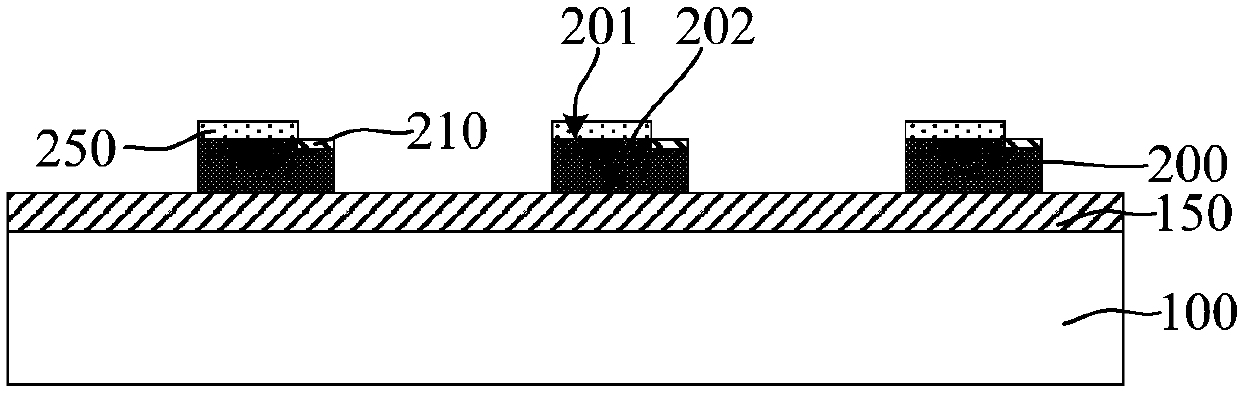

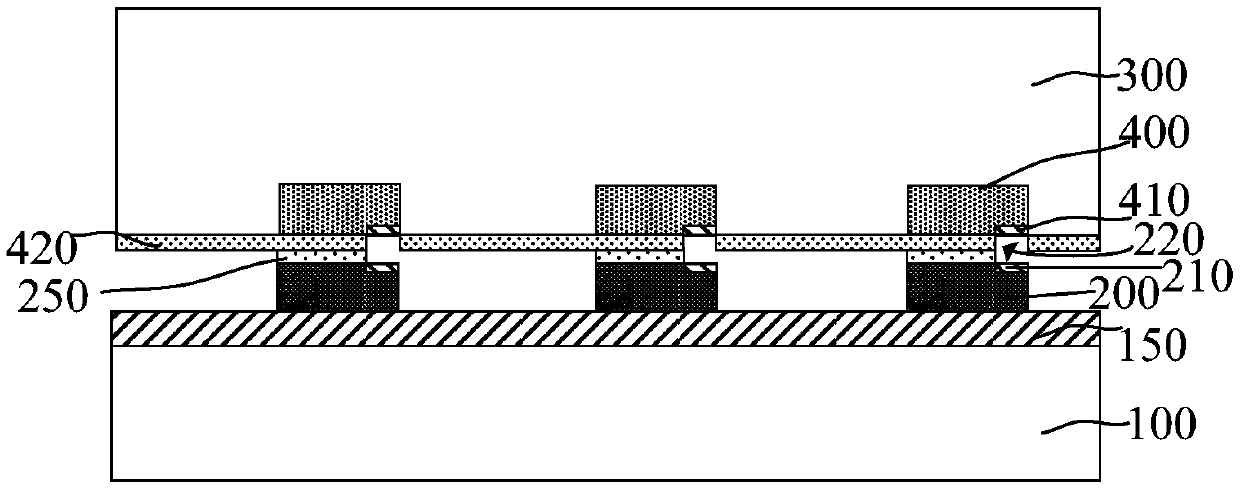

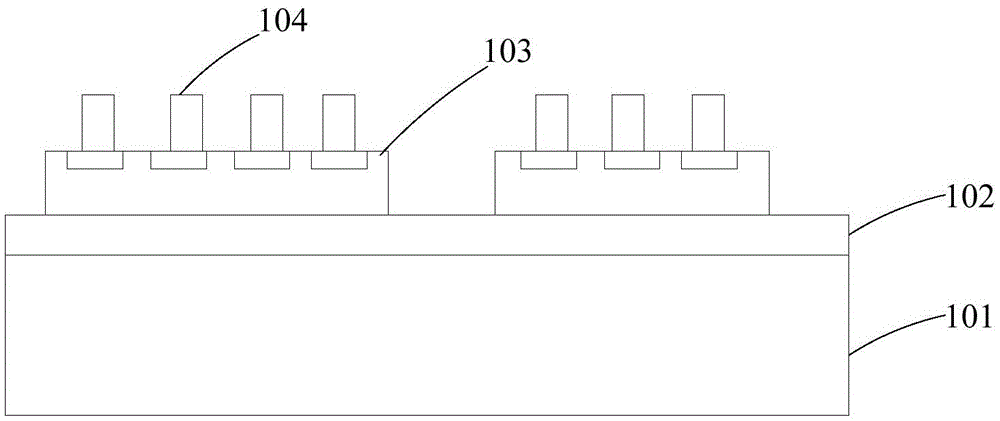

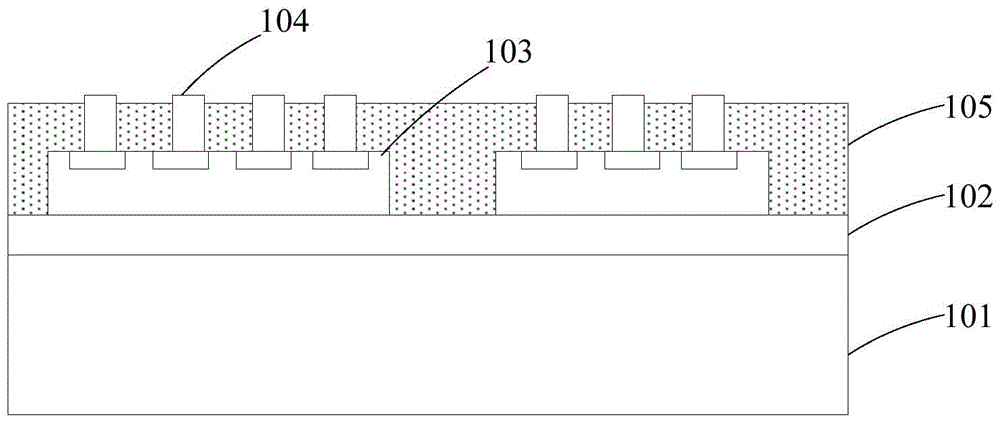

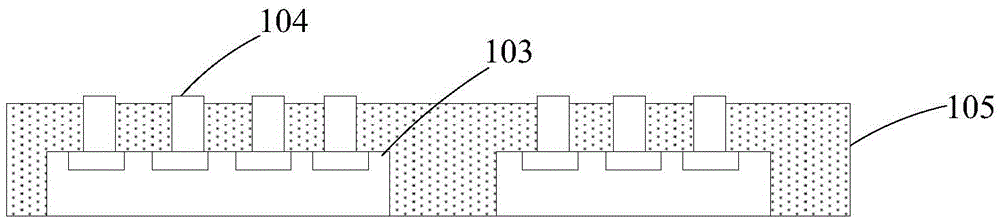

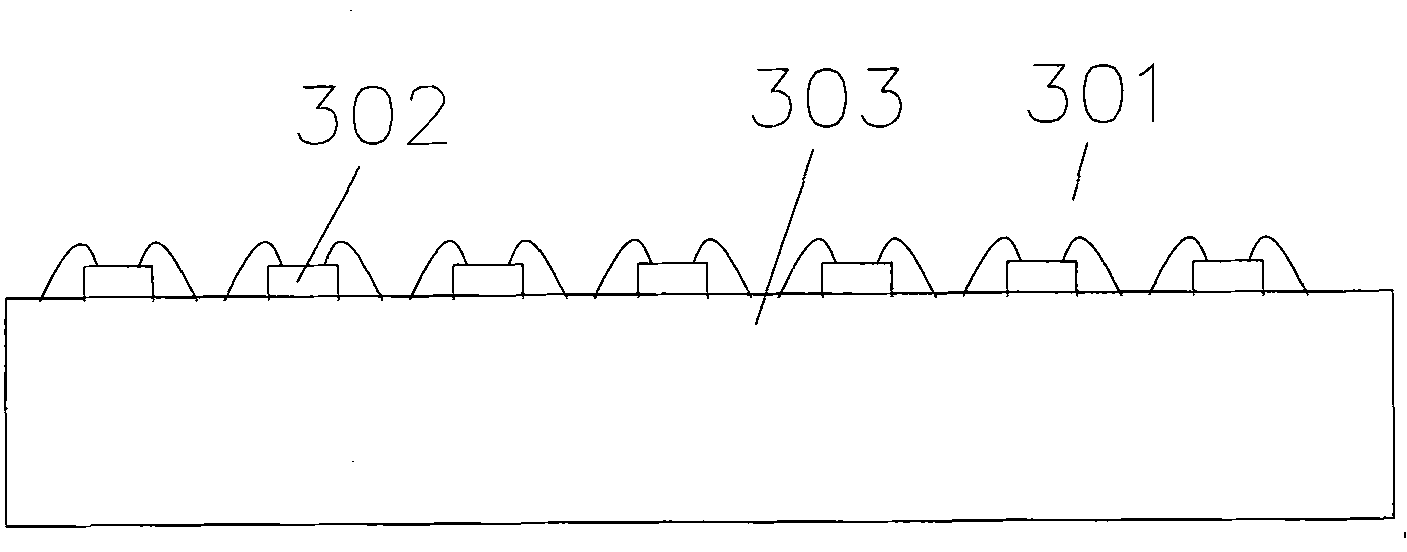

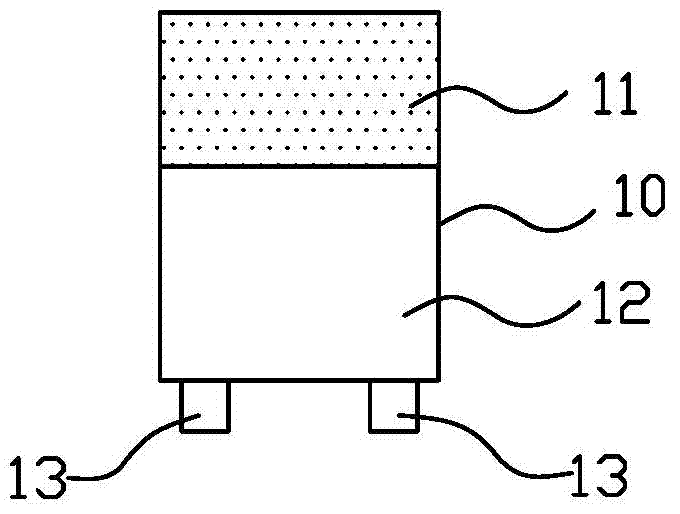

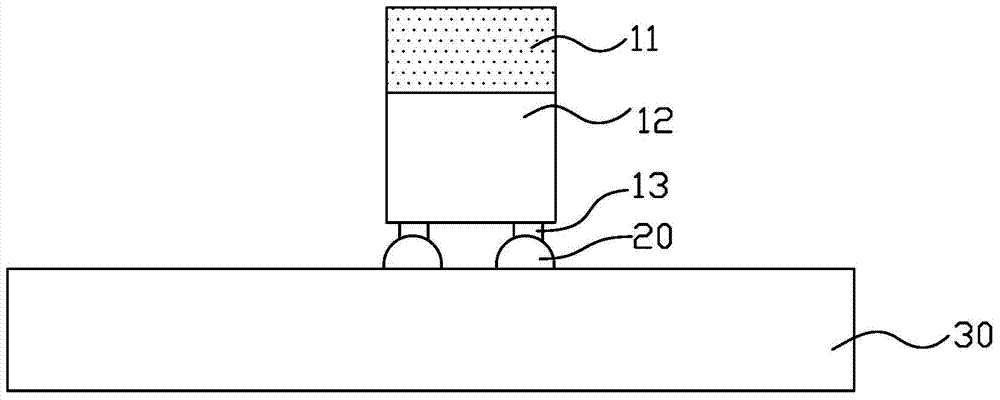

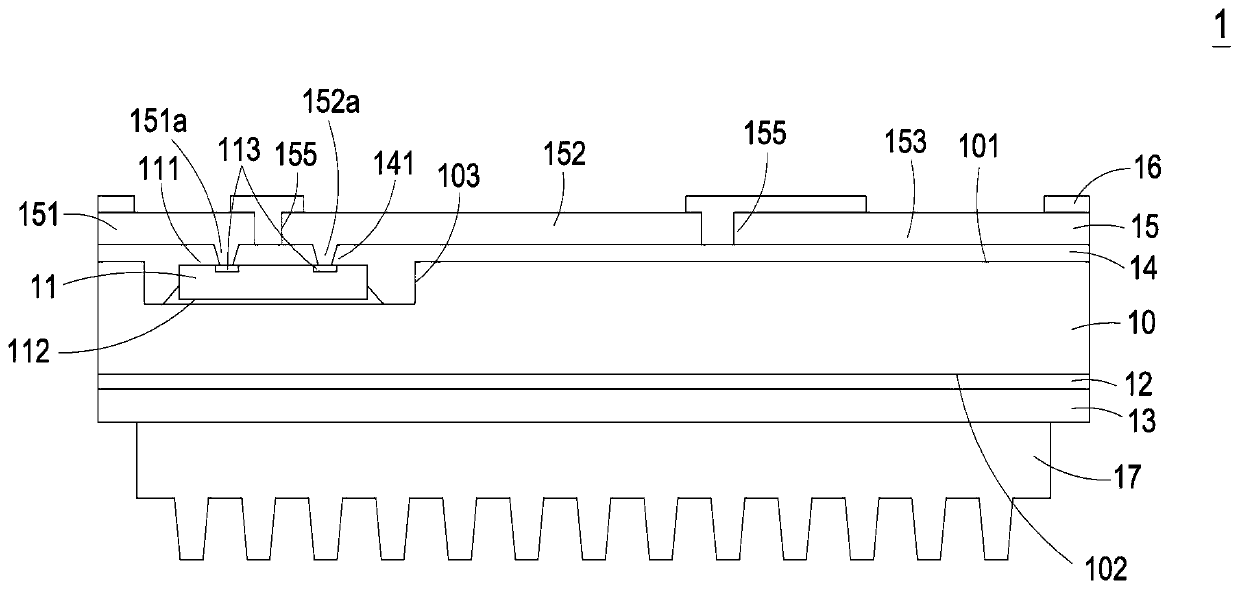

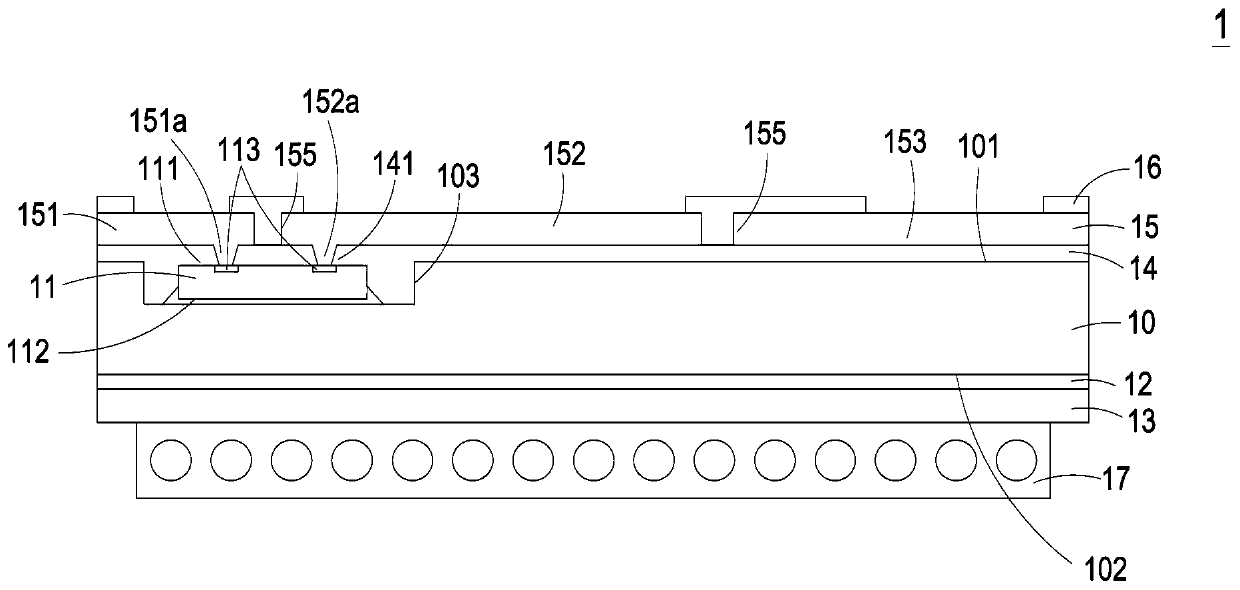

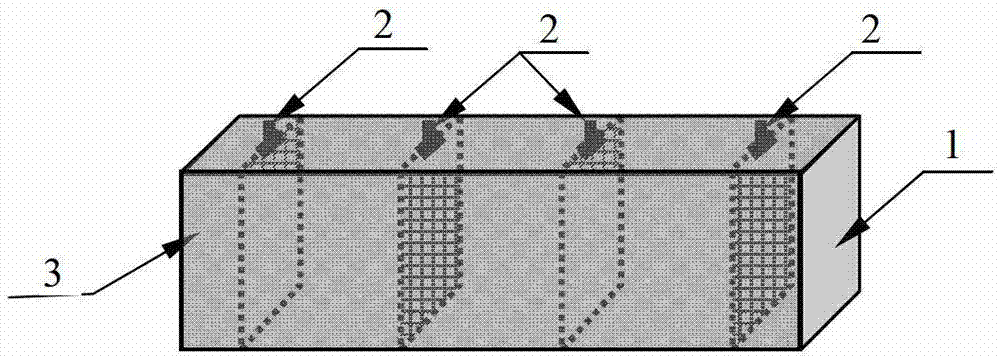

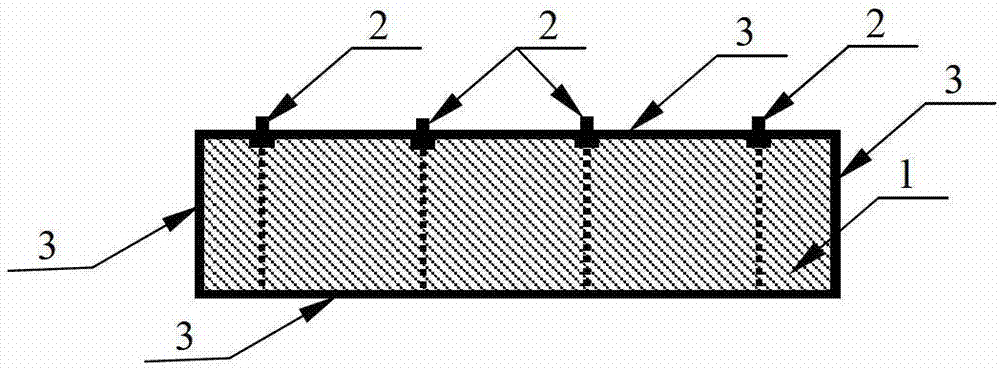

Fingerprint identification chip packaging structure and packaging method

InactiveCN104851813AThe packaging method is simpleReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingEngineering

The invention provides a fingerprint identification chip packaging structure and a packaging method. The packaging method comprises the steps that a substrate is provided; an induction chip is coupled at the surface of the substrate, the induction chip is provided with a first surface and a second surface which is opposite to the first surface, the first surface of the induction chip comprises induction areas, and the second surface of the induction chip is arranged at the surface of the substrate; and a plastic packaging layer is formed at the surfaces of the substrate and the partial induction chip, and the plastic packaging layer is exposed out of the induction areas. Sensitivity of the packaging structure of a fingerprint identification chip is enhanced, the packaging technology is simplified and manufacturing cost is reduced.

Owner:CHINA WAFER LEVEL CSP

Packing box and method for thin film solar cells

Owner:CNBM CHENGDU OPTOELECTRONICS MATERIAL

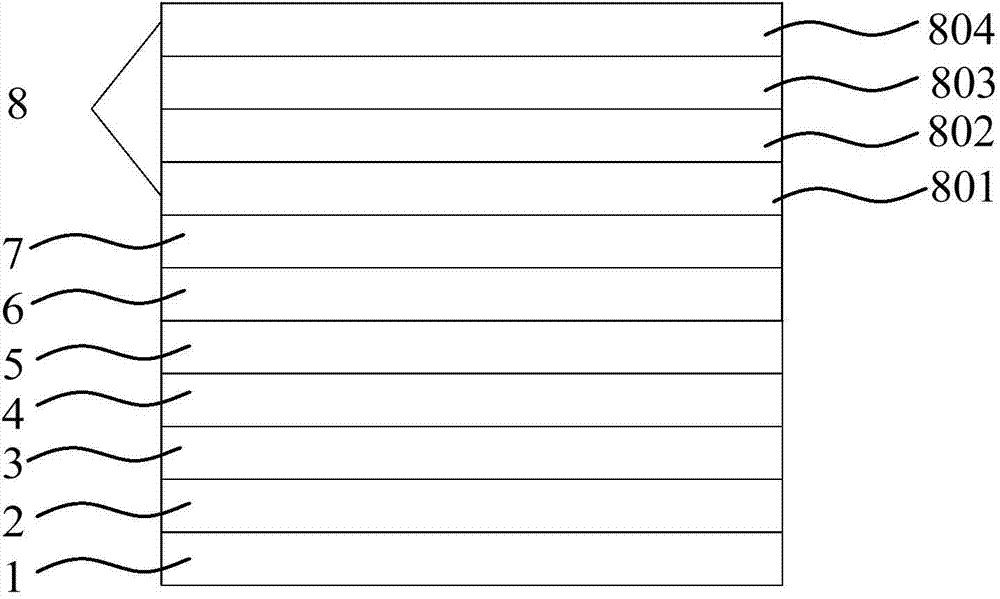

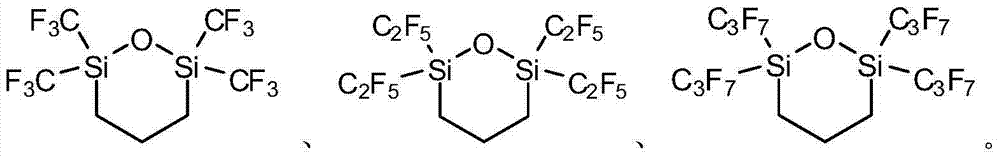

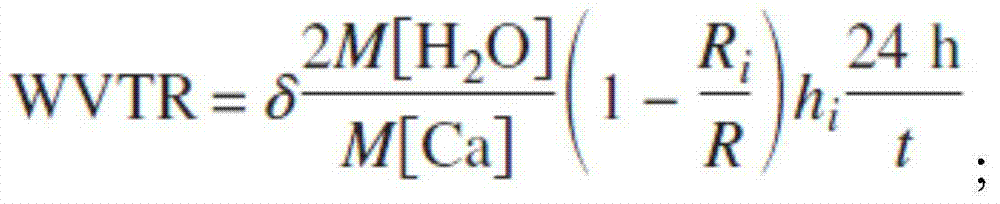

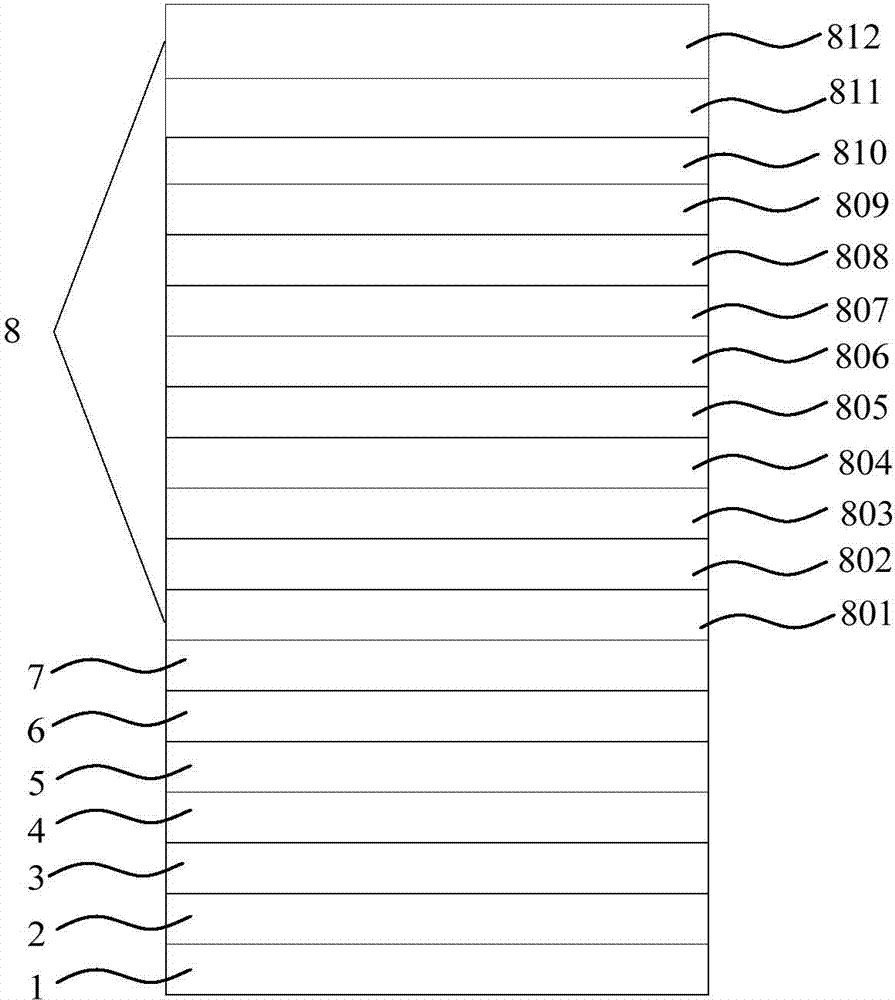

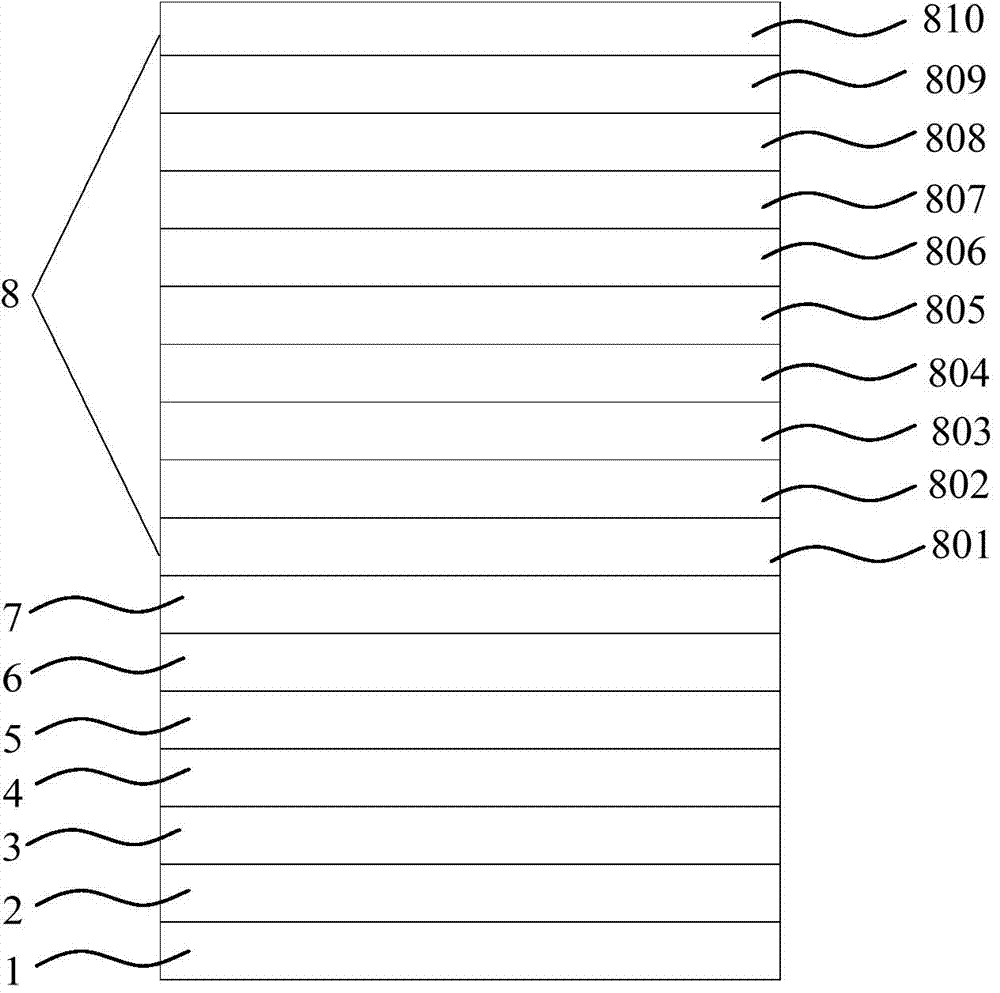

Organic electroluminescent device and preparation method thereof

InactiveCN104518134AImprove the blocking effectExtend your lifeSolid-state devicesSemiconductor/solid-state device manufacturingHole injection layerOxygen

The invention provides an organic electroluminescent device. The organic electroluminescent device comprises an anode conductive substrate, a cavity implantation layer, a cavity transmission layer, a luminescent layer, an electron transmission layer, an electron injecting layer, a cathode layer and a packaging layer which are successively stacked. The anode conductive substrate and the packaging layer form an enclosed space, and the cavity implantation layer, the cavity transmission layer, the luminescent layer, the electron transmission layer and the electron injecting layer and the cathode layer are accommodated in the enclosed space. The packaging layer comprises a protective layer, a fluoride layer, an organic silicon layer and a poly(ethylene terephthalate) membrane which are successively stacked. The invention further provides a preparation method of the organic electroluminescent device. According to the invention, the method can effectively reduce corrosion caused by oxygen and steam to the organic electroluminescent device, forms effective protection of the organic function material of the device and electrodes, and can substantially prolong the life of the organic electroluminescent device. The method is especially suitable for packaging a flexible organic electroluminescent device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

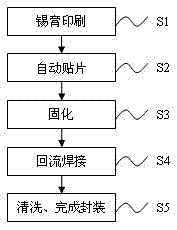

Flip LED chip packaging method and flip LED chip using packaging method

ActiveCN104752595ASimple processComplete EncapsulationSemiconductor devicesReflow solderingSolder paste

The invention discloses a flip LED chip packaging method. The method comprises steps: an epitaxial slice of the flip LED chip is firstly made; a thin film is fixed at the top part of the epitaxial slice; electrodes are made on the epitaxial slice so as to form a flip LED chip; a solder paste is arranged on a substrate to enable two electrodes of the LED chip to be contacted with the solder paste respectively, reflow soldering is then carried out on the substrate and the LED chip on the substrate, and thus the electrodes of the LED chip are soldered on the substrate; and the thin film is heated and melted during the reflow soldering process and coats the LED chip, and then the thin film is cooled and cured to form a packaging layer. In addition, the invention also provides a flip LED chip using the packaging method. The flip LED chip packaging method and the flip LED chip using the packaging method have the advantages of a simple production process.

Owner:LEEDARSON IOT TECH INC

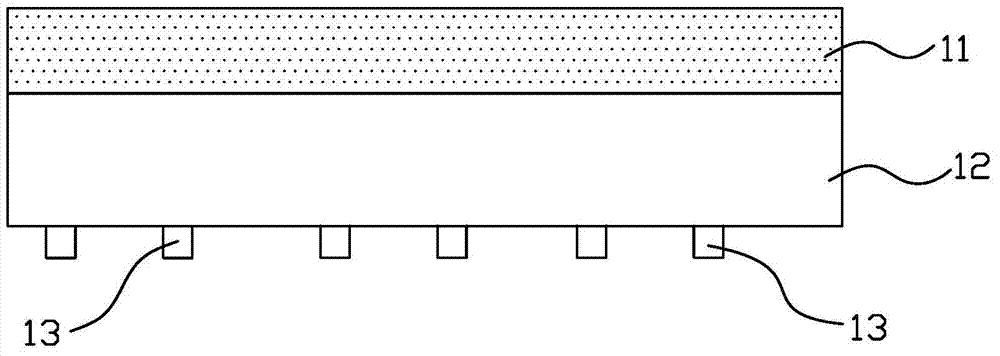

Encapsulating method of flexible OLED device

InactiveCN107565047AThe packaging method is simpleEasy to operateSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringOxygen

The invention relates to an encapsulating method of a flexible OLED device. The encapsulating method comprises: (1), placing an OLED sample prepared in advance between two good barrier films; (2), stacking or manufacturing an air suction laser above the OLED sample; and (3), carrying out barrier film encapsulation by means of hot-pressing contact or adhesion. The encapsulating method has advantages of great simpleness, great easiness in operation, low cost, short period, good sealing performance, and good water and oxygen insulation effect.

Owner:FUZHOU UNIV

Package structure and packaging process

PendingCN111180434AReduce thicknessImprove cooling efficiencySemiconductor/solid-state device detailsSolid-state devicesInsulation layerEngineering

The present invention provides a packaging structure. The package structure includes a carrier, at least one electronic component, a first insulation layer, a heat spreading layer, a second insulationlayer, plural re-distribution blocks, a passivation layer, and a heat dissipation device. The electronic component is disposed in a recess of the carrier and has plural conducting terminals. The first insulation layer is formed on a second surface of the carrier. The heat spreading layer is formed on the first insulation layer. The second insulation layer is formed on a first surface of the carrier. The re-distribution blocks are formed on the second insulation layer. Each re-distribution block includes at least one conductive via disposed in the second insulation layer and in contact with corresponding one of the conductive terminals. The passivation layer is formed on the re-distribution blocks and covers portions of the re-distribution blocks. The heat dissipation device is disposed onthe heat spreading layer.

Owner:DELTA ELECTRONICS INTL SINGAPORE

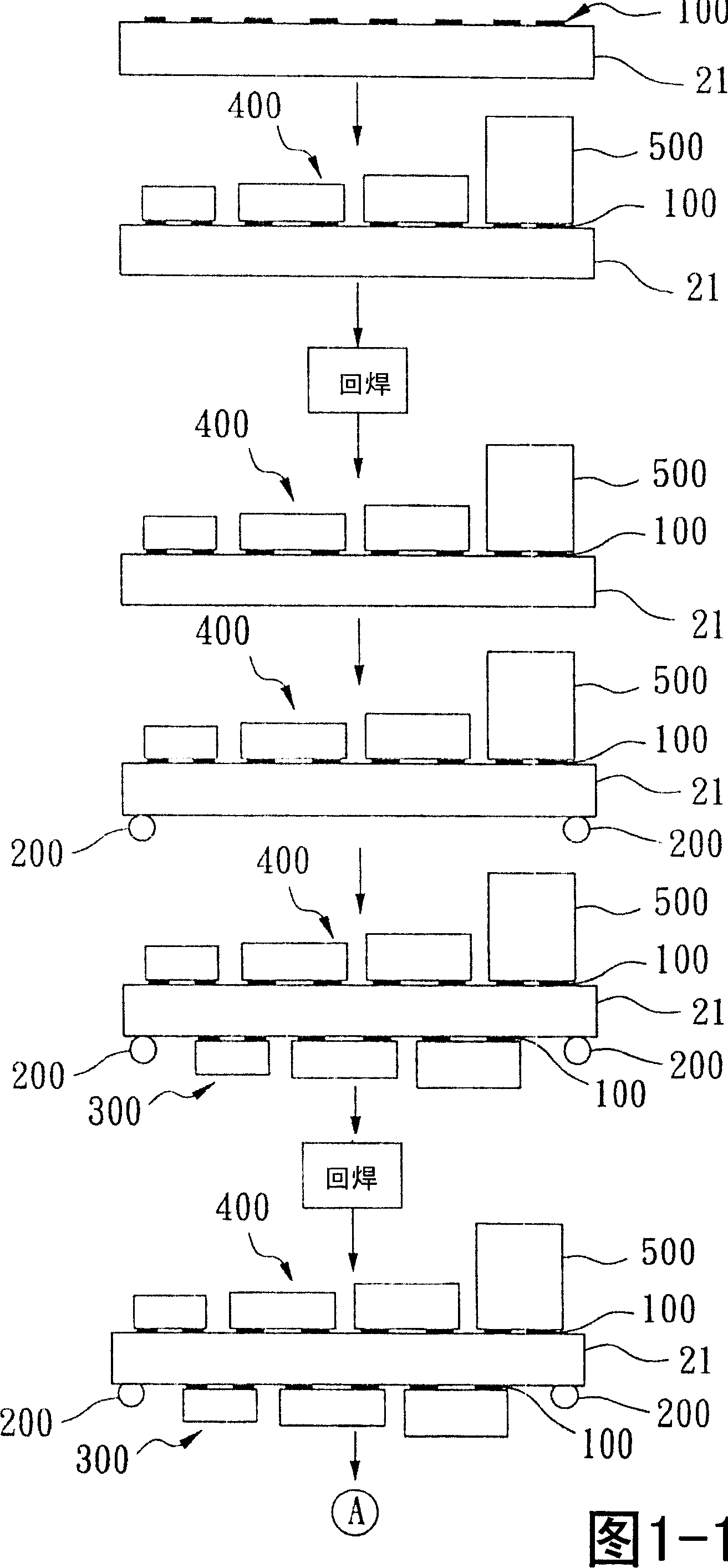

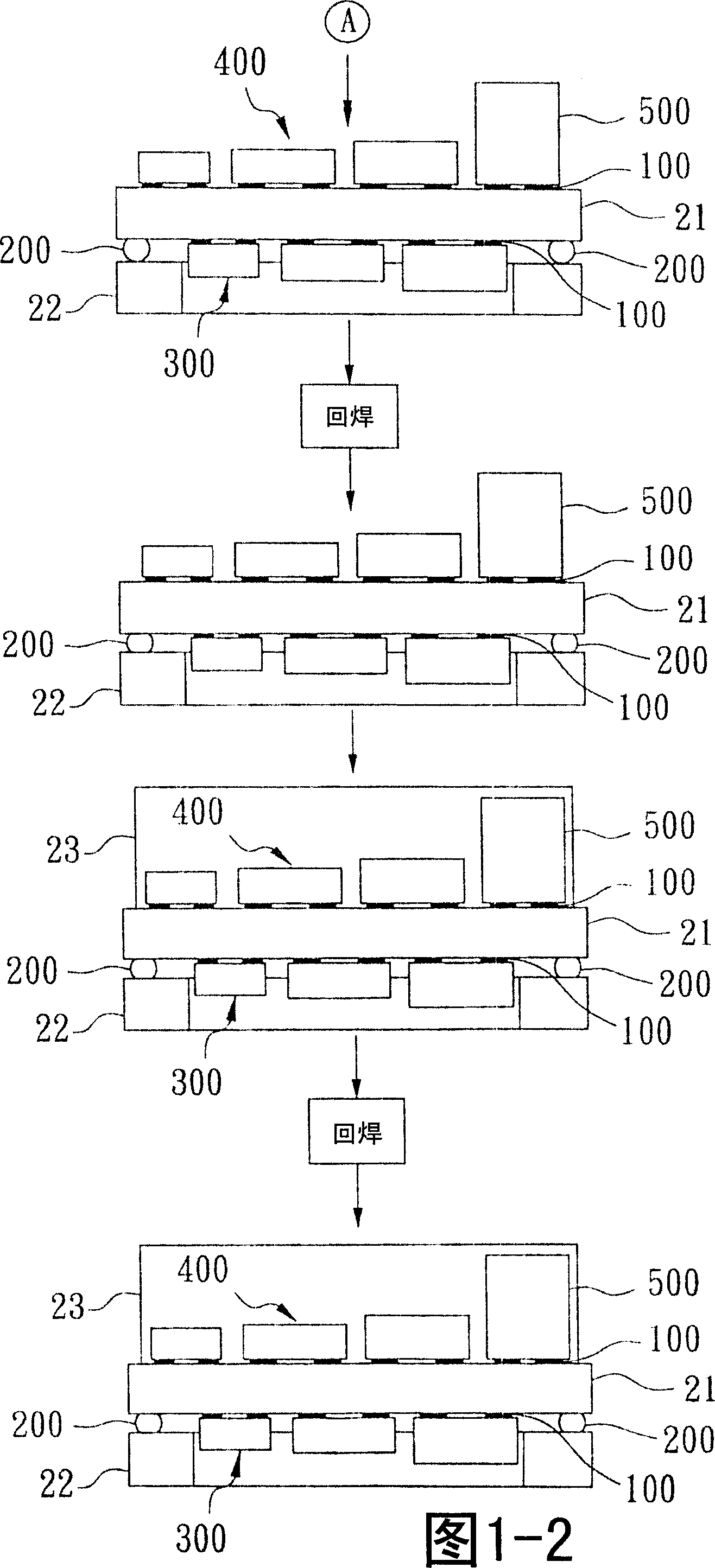

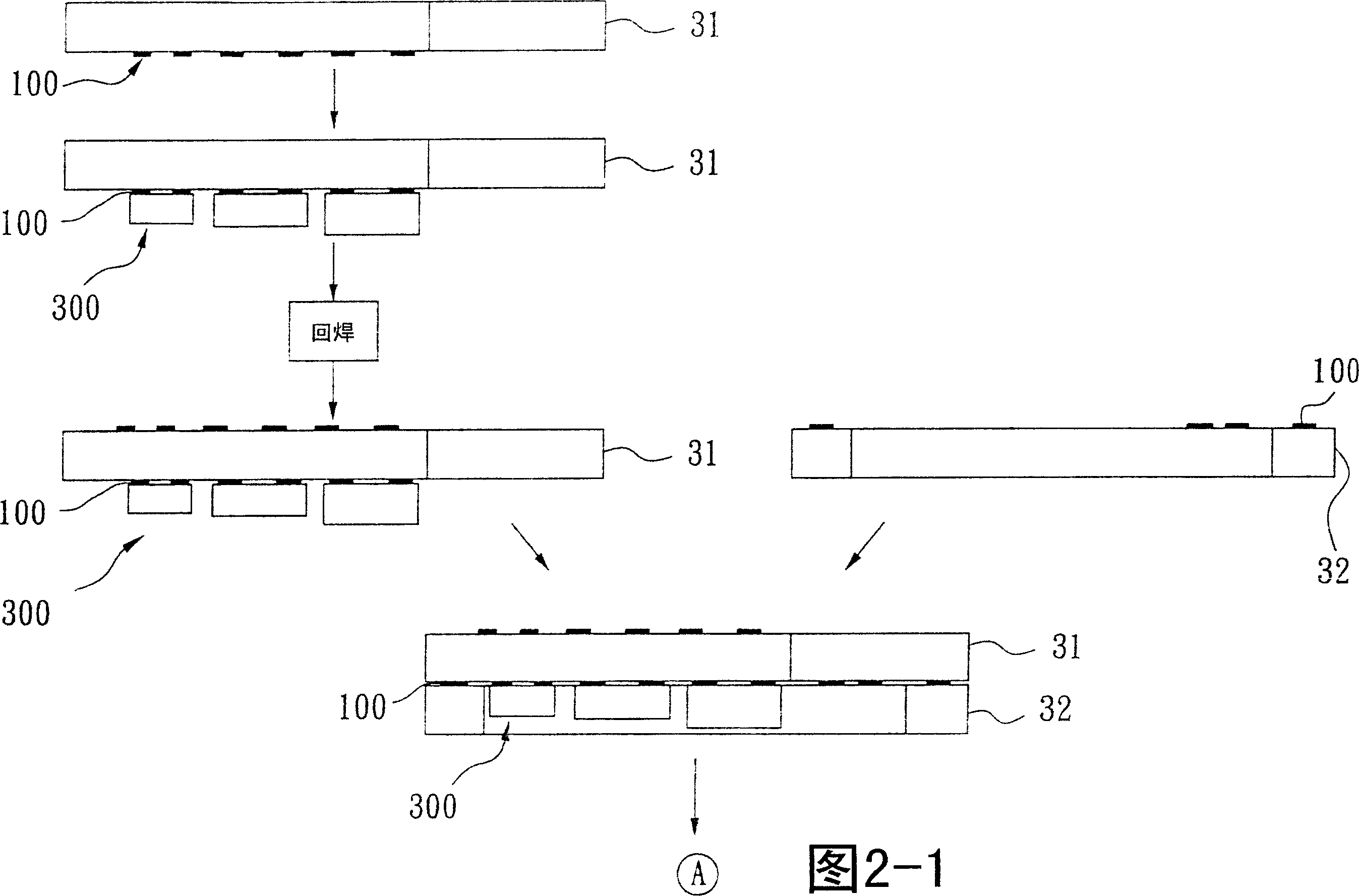

Encapsulation method of dual base board electronic module for the radio communication

ActiveCN101035415AThe packaging method is simpleSmall sizePrinted circuit assemblingSemiconductor/solid-state device manufacturingElectricityEngineering

The encapsulated method is apply printed stannous oilment congruence assemble upper and nether substrate, and bring to bear preconcerted press decrease total thickness of upper and nether substrate, at one time, synchronously position Scheduled setting one upper and nether substrate, and after hood the shell of protected the element, then can through once welding course simultaneous fix up each other upper and nether substrate and Electrical Connectors, multi-electronic component and filter component difference set on tip of upper and nether substrate, and shell fix up on the face of the upper substrat, and that can predigest all process of encapsulation, and gain the electromodule which have been cutted dimension.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD

Pressurized pipeline type water purifier and packaging method thereof

ActiveCN105585161AReduce in quantityImprove assembly efficiencyWater/sewage treatment by irradiationSpecific water treatment objectivesWater leakageTap water

The invention provides a pressurized pipeline type water purifier and a packaging method thereof. The pressurized pipeline type water purifier comprises a front composite filter element and a composite RO (reverse osmosis) membrane reverse osmosis filter element, wherein a tap water inlet is formed in the front end of the front composite filter element; a pure water outlet and a concentrated water outlet are formed in the rear end of the composite RO membrane reverse osmosis filter element. Pure water is obtained through matched use of the front composite filter element and the composite RO membrane reverse osmosis filter element, the two filter elements are directly connected or connected through a connection pipeline, common PE (polyethylene) pipeline connection in an RO filtering machine is eliminated, water leakage points and the number of filter flasks are reduced, and the assembly efficiency of the water purifier is improved. The front composite filter element is connected with a pressurizing device, during quick water production, initially filtered water enters the pressurizing device from a low-pressure water outlet for pressurization and then flows into the composite RO membrane reverse osmosis filter element through a central high-pressure water outlet pipe, the water production capacity is improved, an RO membrane can be washed, and the service life of the RO membrane is prolonged.

Owner:RICHU DONGFANG SOLAR ENERGY

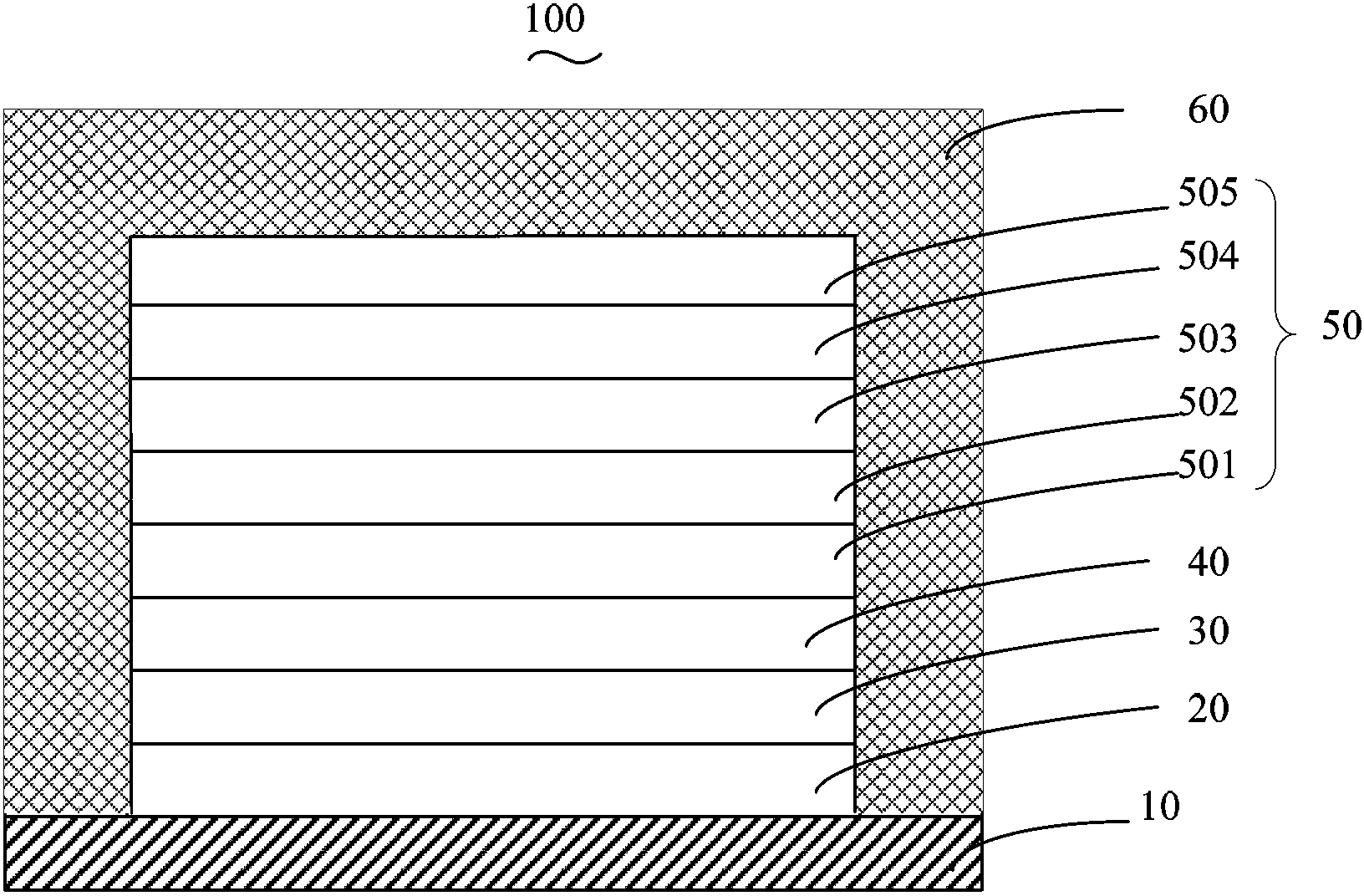

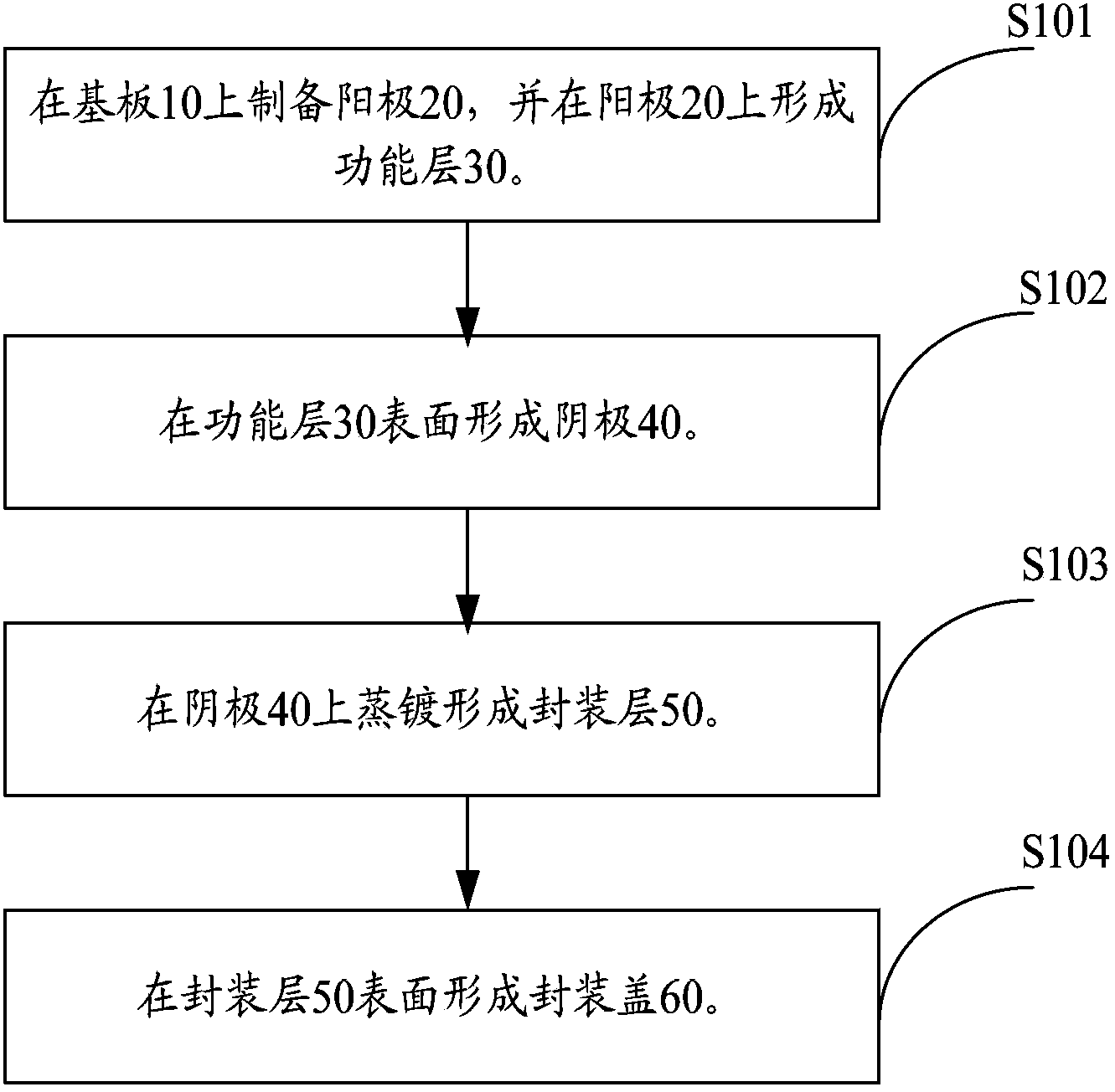

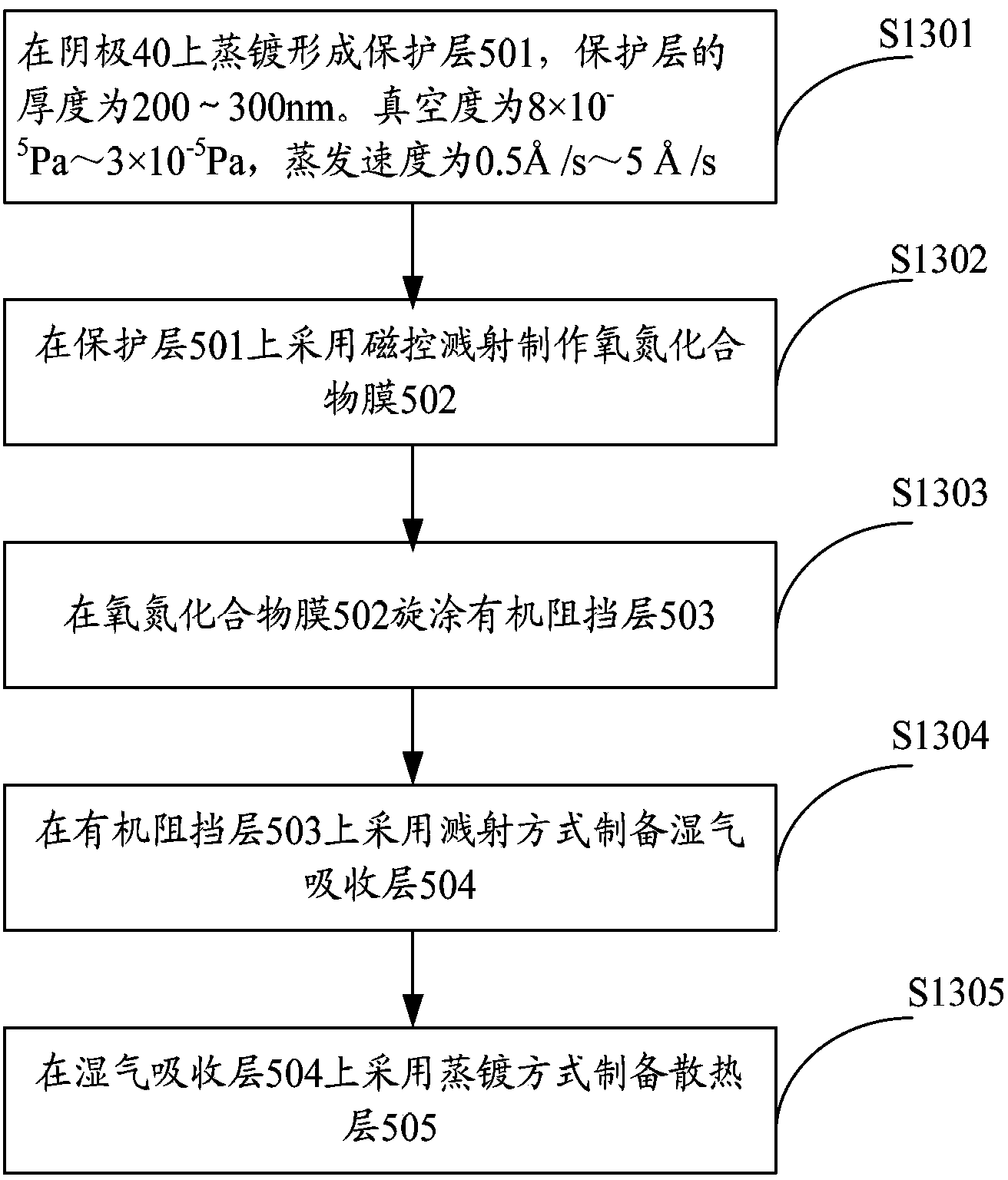

Organic light-emitting device and preparation method thereof

InactiveCN103855321AReduce erosionExtend your lifeSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringOxygen

Provided in the invention is an organic light-emitting device comprising a substrate, an anode, a functional layer, a cathode, a packaging layer, and a packaging cover. The substrate, the anode, the functional layer, the cathode, the packaging layer, and the packaging cover are successively laminated. The substrate and the packaging cover form an enclosed space; and the anode, the functional layer, the cathode, and the packaging layer are accommodated into the enclosed space. The packaging layer successively includes a protection layer, an oxygen-nitrogen compound film, an organic blocking layer, a moisture absorbing layer, and a cooling layer; and the oxygen-nitrogen compound film is an oxide film doped with nitride. In addition, the invention also provides a preparation method of the organic light-emitting device. With the method, erosion on the organic light-emitting device by moisture and oxygen can be effectively reduced, so that the device organic functional material and the electrode can be effectively protected and thus the service life of the organic light-emitting device can be obviously prolonged. The method is especially suitable for packaging of a flexible organic light-emitting device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

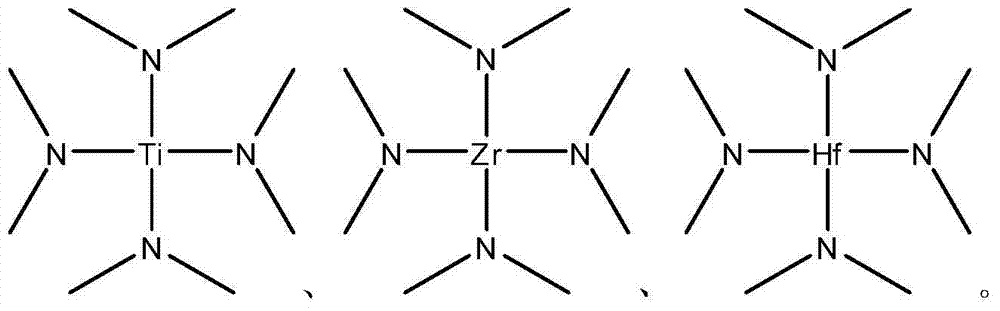

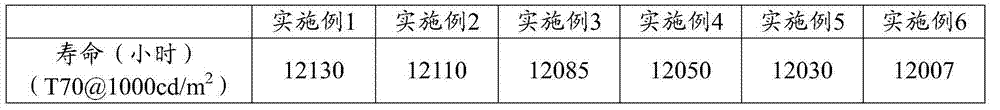

Organic light emitting diode device and preparation method thereof

InactiveCN104518154AReduce erosionExtend your lifeSolid-state devicesSemiconductor/solid-state device manufacturingFlexible organic light-emitting diodePhthalocyanine

The invention provides an organic light emitting diode device. The organic light emitting diode device includes an anode electric conduction substrate, a hole injection layer, a hole transport layer, a light-emitting layer, an electron transport layer, an electron injection layer, a cathode layer and an encapsulation layer which are stacked to one another sequentially; the anode electric conduction substrate and the encapsulation layer form a closed space; the hole injection layer, the hole transport layer, the light-emitting layer, the electron transport layer, the electron injection layer and the cathode layer are accommodated in the closed space; and the encapsulation layer includes hybrid barrier layers and inorganic barrier layers which are stacked sequentially, wherein the hybrid barrier layers are made of a mixture of phthalocyanine, fluoride, an organic material and an oxide, and the inorganic barrier layers are made of titanium dioxide, zirconium dioxide or hafnium dioxide. The method provided by the invention is especially suitable for the encapsulation of flexible organic light emitting diode devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Encapsulation structure and method of micro electro mechanical system device

InactiveCN107055456AImprove air tightnessThe packaging method is simpleDecorative surface effectsSolid-state devicesMicroelectromechanical systemsAir tightness

The invention discloses an encapsulation structure and method of a micro electro mechanical system device. The encapsulation structure of the micro electro mechanical system device comprises a first wafer and a second wafer; the first wafer is provided with a first central region and a first marginal region surrounding the first central region; the second wafer is provided with a second central region and a second marginal region surrounding the second central region; a first closed space is formed between the first central region and the second central region by correspondingly binding the first binding structure of the first marginal region and the second binding structure of the second marginal region together, namely, the micro electro mechanical system device in the first wafer is located in the closed space; the encapsulation structure of the formed micro electro mechanical system device is excellent in sealing; and the manufacturing procedure of the second wafer is simple and easy and free from additional processing. Therefore, the encapsulation structure of the micro electro mechanical system device disclosed by the invention is good in air tightness, simple and easy in encapsulation method, and low in production cost.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Carbon nanometer tube cement based composite material sensor encapsulating method

InactiveCN103033207AThe measurement data is reliableStrong bondMeasurement apparatus componentsCorrosion resistantCarbon nanotube

The invention discloses a carbon nanometer tube cement based composite material sensor encapsulating method. A protecting cover is covered on a carbon nanometer tube cement based composite material sensor metal binding post. A thin layer of coating or adhesive substances is evenly painted on each surface of a sensor prismoid, wherein the coating or the adhesive substances are corrosion-resistant, heat-insulating, humid-preventing, insulating, and capable of being hardened. Before the coating or the adhesive substances are completely hardened, roughening is conducted on the surfaces so as to enable the surfaces to be rough enough. The protecting cover is removed from the carbon nanometer tube cement based composite material sensor metal binding post, and a sensor is encapsulated after the coating is completely hardened. After encapsulated through the method, the carbon nanometer tube cement based composite material sensor has the advantages of being corrosion-resistant, heat-insulating, humid-preventing, insulating, and the like, is not influenced by outside environments in project structure health monitoring, is reliable in detected data, and reduces detection errors. Moreover, the sensor can be firmly adhered to concrete environment media.

Owner:SHANDONG UNIV OF SCI & TECH

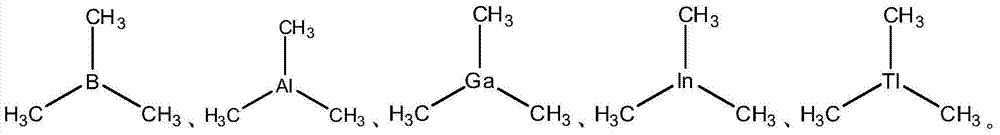

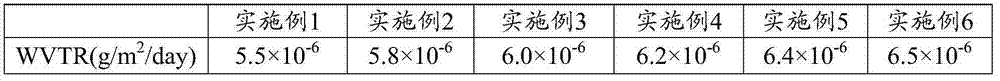

Organic light emitting diode device and preparation method thereof

InactiveCN104518110AHigh purityGood shape retentionSolid-state devicesSemiconductor/solid-state device manufacturingFlexible organic light-emitting diodeIndium

The invention provides an organic light emitting diode device. The organic light emitting diode device includes an anode electric conduction substrate, a hole injection layer, a hole transport layer, a light-emitting layer, an electron transport layer, an electron injection layer, a cathode layer and an encapsulation layer which are stacked to one another sequentially; the anode electric conduction substrate and the encapsulation layer form a closed space; the hole injection layer, the hole transport layer, the light-emitting layer, the electron transport layer, the electron injection layer and the cathode layer are accommodated in the closed space; and the encapsulation layer includes silicon carbonitride layers and inorganic barrier layers which are stacked sequentially, wherein the inorganic barrier layers are made of boric oxide, aluminum oxide, gallium oxide, indium oxide or thallium oxide. The method provided by the invention is especially suitable for the encapsulation of flexible organic light emitting diode devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com