Microelectromechanical system micromirror package

A system of micro-mirror and micro-electromechanical technology, applied in circuits, electrical components, electrical solid-state devices, etc., can solve problems such as large structure and inapplicability, and achieve the effect of improving production efficiency, saving costs, and facilitating miniaturization and integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

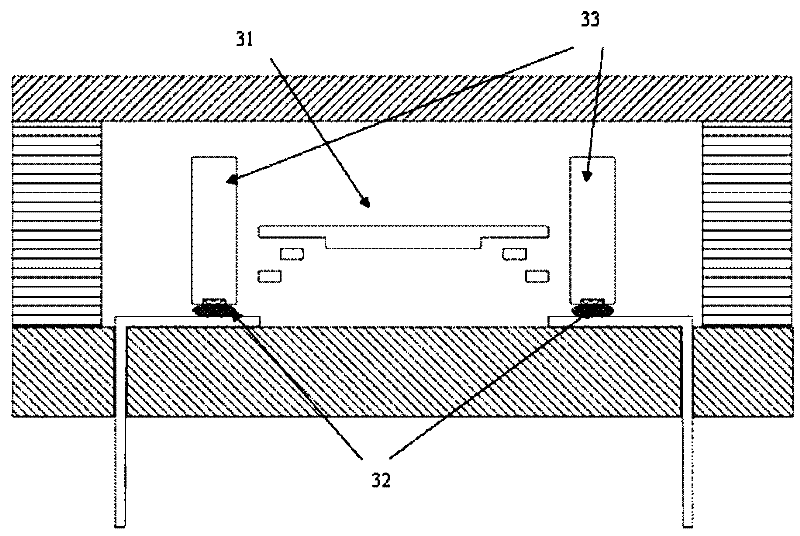

[0036] Such as Figure 4 As shown, the microelectromechanical system micromirror is packaged in an airtight cavity formed by the top transparent cover sheet 40, the silicon frame 44 around the micromirror, and the bottom substrate 45. The top transparent cover sheet and the bottom substrate 45 do not have electrical connections. The plate 47 faces the same direction as the micromirror mirror surface 43, and a through hole 46 is opened on the top transparent cover sheet, and the through hole is facing the pad 46 on the micromirror chip. The upper surface of the top transparent cover sheet has an optical coating 41 and a coating window 42, and the coating window 42 is facing the micromirror mirror surface 43; the lower surface has an inwardly recessed cavity.

[0037] Figure 5 Shown is a bulk micromirror with a different orientation between the pad and the micromirror mirror surface. The microelectromechanical system micromirror is packaged in a closed cavity composed of a top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com