Organic light emitting diode device and preparation method thereof

An electroluminescent device and luminescent technology, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of short life, affect the life of the device, increase the weight of the device, etc., and prevent the erosion of water and oxygen , Good shape retention and high compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

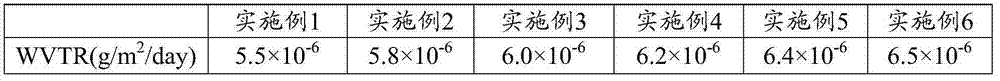

Embodiment 1

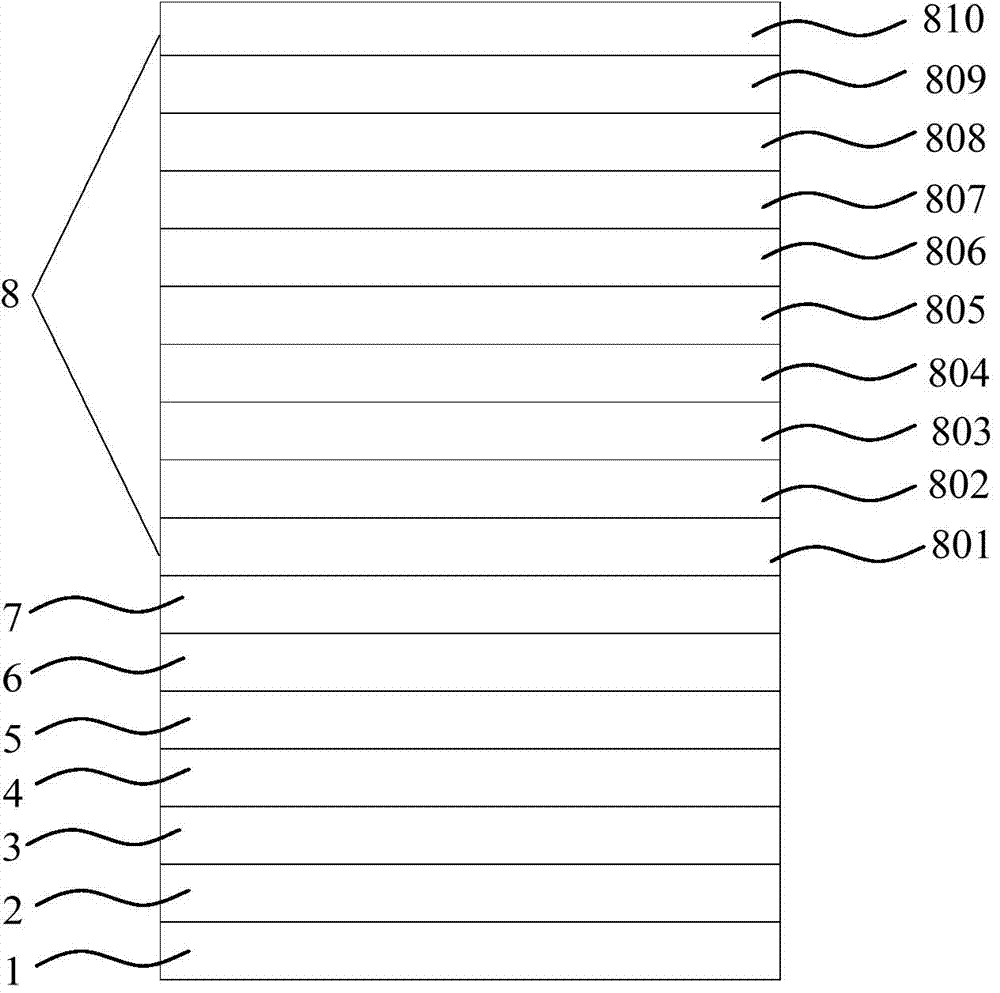

[0062] A method for preparing an organic electroluminescent device, comprising the following steps:

[0063] (1) Pre-treatment of ITO conductive glass substrate 1: put ITO conductive glass substrate 1 into acetone, ethanol, deionized water, and ethanol in sequence, ultrasonically clean them for 5 minutes, then blow dry with nitrogen, and dry them in an oven for later use; The cleaned ITO glass substrate 1 is subjected to surface activation treatment to increase the oxygen content of the conductive surface layer and improve the work function of the conductive layer surface; the thickness of the ITO glass substrate 1 is 100nm;

[0064] Hole injection layer 2: Evaporate MoO on the ITO conductive glass substrate 1 3 The mixed material obtained by doping NPB, the doping mass fraction of MoO3 in NPB is 25%, and the evaporation is carried out by high vacuum coating equipment, and the vacuum degree during evaporation is 3×10 -5 Pa, the evaporation rate is A hole injection layer 2 i...

Embodiment 2

[0082] A method for preparing an organic electroluminescent device, comprising the following steps:

[0083] Step (1) is the same as embodiment 1;

[0084] (2) Place the organic electroluminescent device sample in a plasma-enhanced chemical vapor deposition chamber, the silicon source and carbon source are methyl silane, and the nitrogen source is NH 3 , while passing into H 2 , the flow of methyl silane is 8 sccm, the flow of ammonia is 24 times of the flow of methyl silane, H 2 The flow rate is 205sccm, and the thickness of the silicon nitride carbide layer is 140nm;

[0085] (3) On the silicon carbonitride layer, an inorganic barrier layer was prepared by atomic layer deposition, and the material of the inorganic barrier layer was Al 2 o 3 ;

[0086] A preparation cycle for preparing an inorganic barrier layer is:

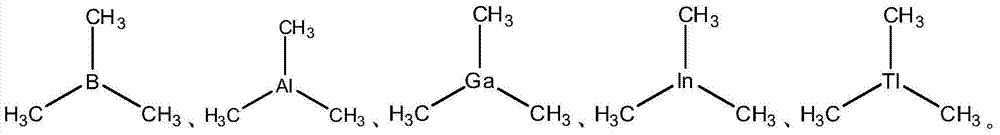

[0087] (a) Al(CH 3 ) 3 The nitrogen gas is injected into the deposition chamber of the atomic layer deposition system and deposited on the silicon carbo...

Embodiment 3

[0095] A method for preparing an organic electroluminescent device, comprising the following steps:

[0096] Step (1) is the same as embodiment 1;

[0097] (2) Place the organic electroluminescent device sample in a plasma-enhanced chemical vapor deposition chamber, the silicon source and carbon source are methyl silane, and the nitrogen source is NH 3 , while passing into H 2 , the flow of methyl silane is 6 sccm, the flow of ammonia is 21 times of the flow of methyl silane, H 2 The flow rate is 210sccm, and the thickness of the silicon carbide layer is 140nm;

[0098] (3) The inorganic barrier layer was prepared by atomic layer deposition on the silicon carbonitride layer, and the material of the inorganic barrier layer was Ga 2 o 3 ;

[0099] A preparation cycle for preparing an inorganic barrier layer is:

[0100] (a) Ga(CH 3 ) 3 The nitrogen gas is injected into the deposition chamber of the atomic layer deposition system and deposited on the silicon carbonitride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com